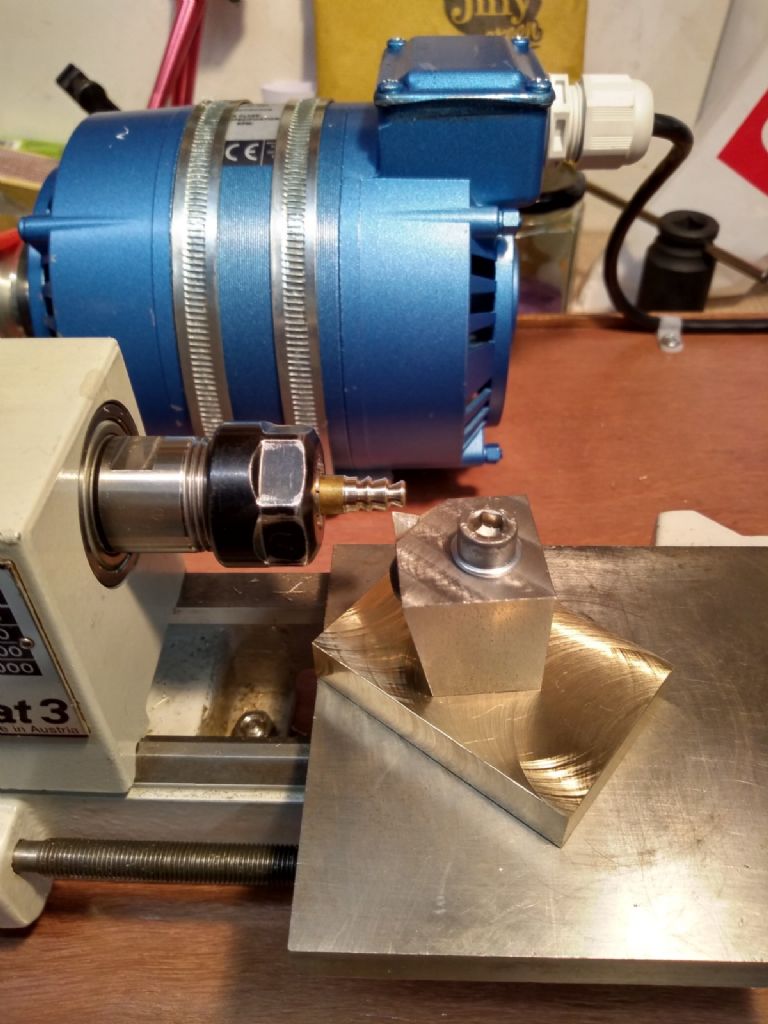

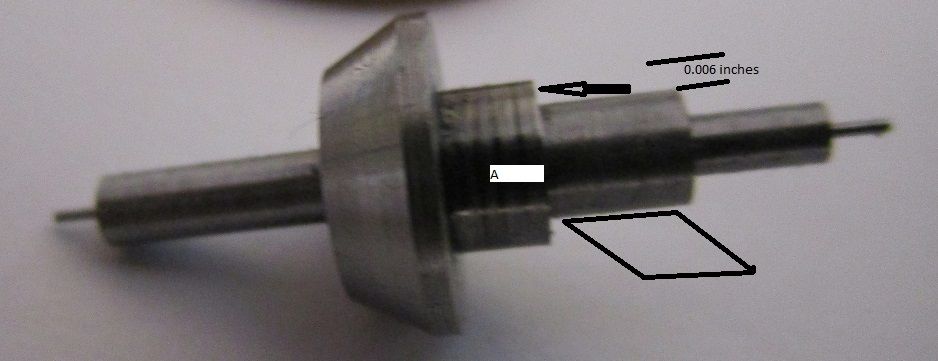

Hi, I have been learning to use my Sherline lathe whilst simultaneously attempting to make a balance staff for a platform escapement off a clock. I have now largely succeeded as you can see from the photo of the first one i made from mild steel for practice. I have been using quality brazed carbide cutters upon recommendation and founfd this advice largely holds as the cutters have held their edge and no chips can be seen.

Hi, I have been learning to use my Sherline lathe whilst simultaneously attempting to make a balance staff for a platform escapement off a clock. I have now largely succeeded as you can see from the photo of the first one i made from mild steel for practice. I have been using quality brazed carbide cutters upon recommendation and founfd this advice largely holds as the cutters have held their edge and no chips can be seen.

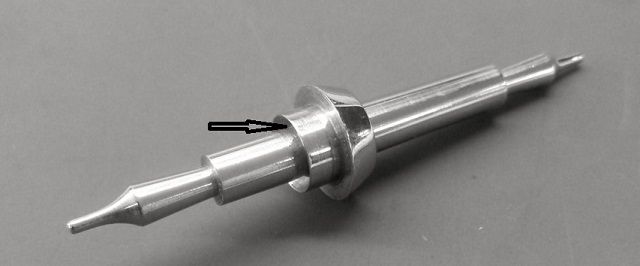

So why the post well if you look at the photo one of the things it is necessary to produce is an undercut shown with the arrow. Baring in mind the cutter has to enter the shoulder without reducing the shoulder length on A you can understand with only a few thou this is delicate work. I would add I do this machining under optics otherwise not possible. Various questions arise as to possible improvements to cutters used as follows;

1. The cutters I have used are termed super carbide as they resist chipping and hold their edge, they come pre-sharpened. However they are U.S products (Micro-100) do we make anything equivalent?

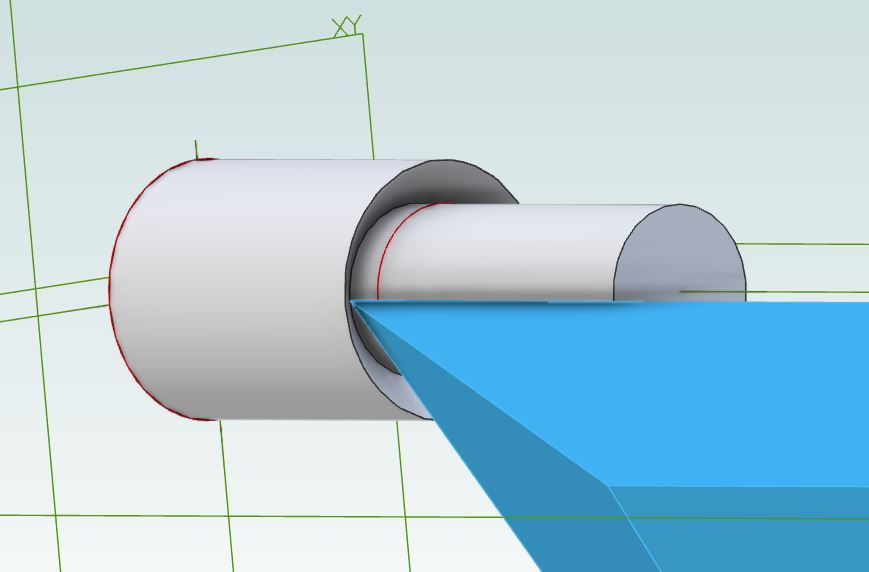

2. Posters have argued that aluminium inserts could be used to machine silver steel that being the case I have been wondering if the 35 degree aluminium rhombus in a suitable holder would be suitable for machining the undercut having a sharp angle. I realise that sharper angles wear more quickly just wondered if only used for this small usage whether it is suitable. If it is can anyone suggest a holder for the V shape rhombus for something usable on the Sherline. The Sherline comes with 1/4 inch tool posts but there are 5/16 and 3/8 posts which I also have.

Regards

Chris

Ian P.

Ian P.

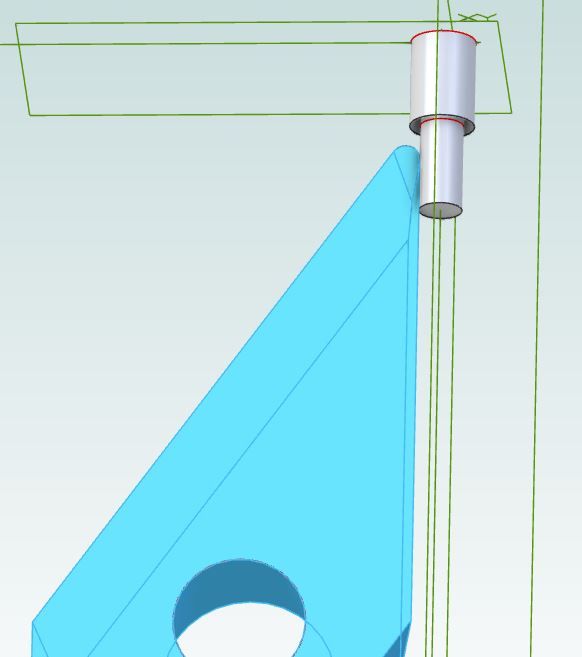

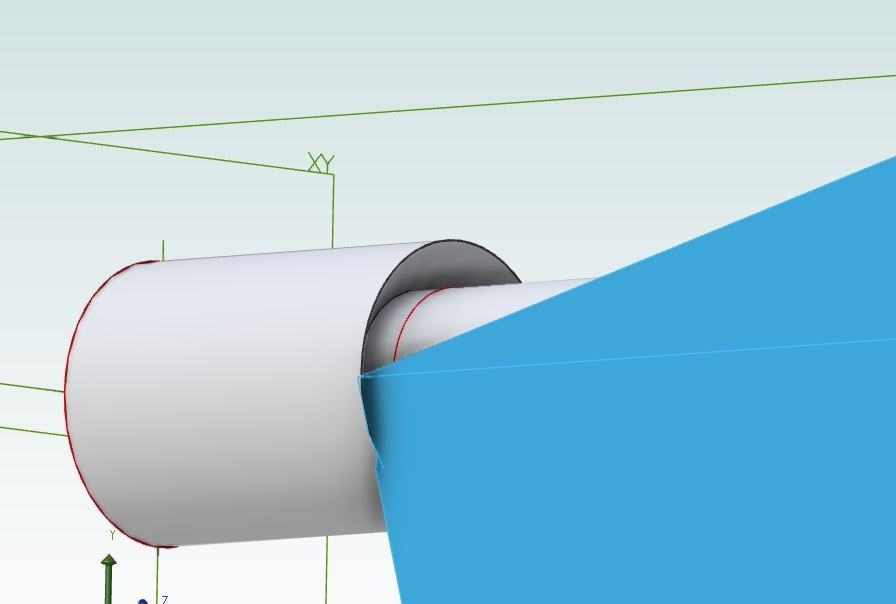

tool – here is a description of one I made for the Unimat.

tool – here is a description of one I made for the Unimat.