Hi @Richard! Thanks for the detailed photos. These are really helpful!

Re the caps. I think we need to backtrack a bit here. Something does not feel right after I have read your whole thread again.

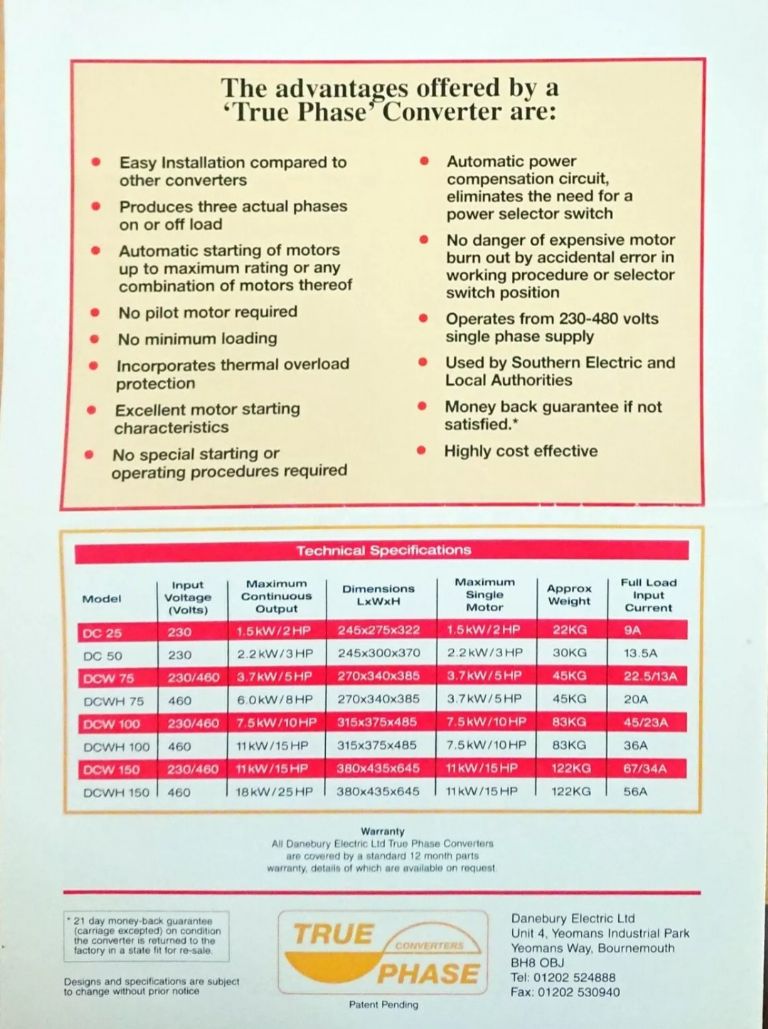

Your RPC needs to be designed to work with your electrical motor installed. Did you do that or did you simply match the lathe's motor to the RPC's output voltage and kW rating and bought the RPC based on those two parameters?

I brushed up on my RPC knowledge and you will need:

1. Two running caps rated at at least 370VAC or higher

2. One starting cap to start the idler motor rated at at least 250VAC or higher.

3. There must be some form of disconnector to disconnect the starting cap after the idler motor has started. You will need to find this and determine what it is. I can be a relay, a timer, a bimetal heat based switch.

4. Overload protector to protect the RPC if it is still running and the mains power goes down and comes back up again while it is still running. I think the orange box is wired for this but not sure.

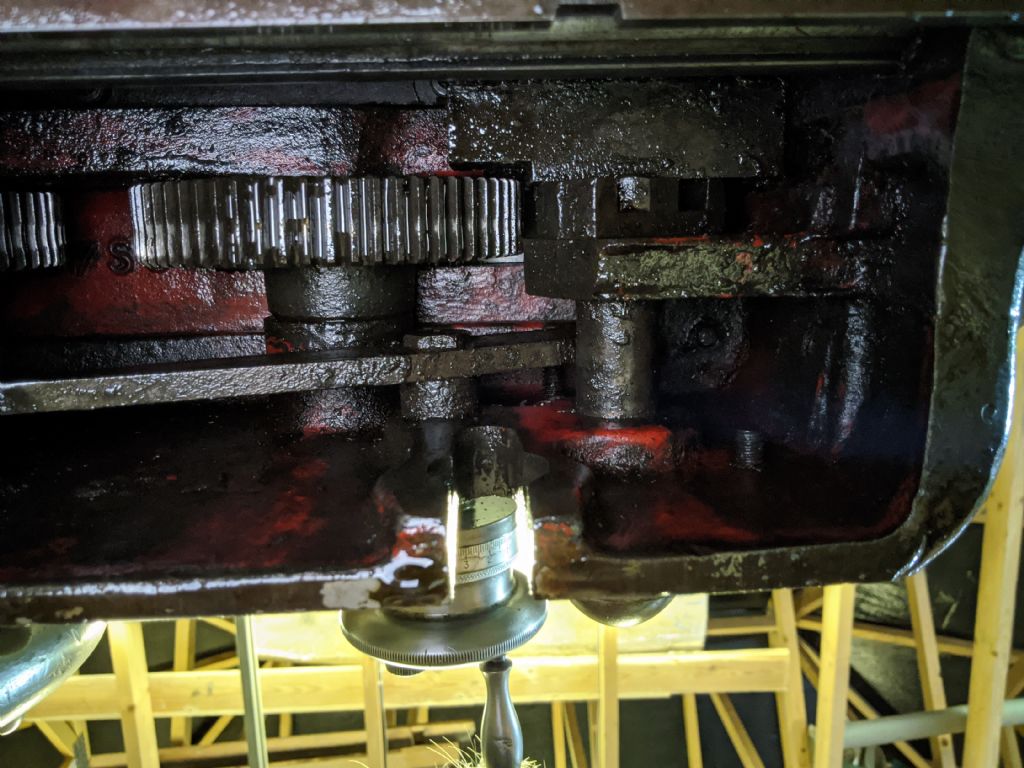

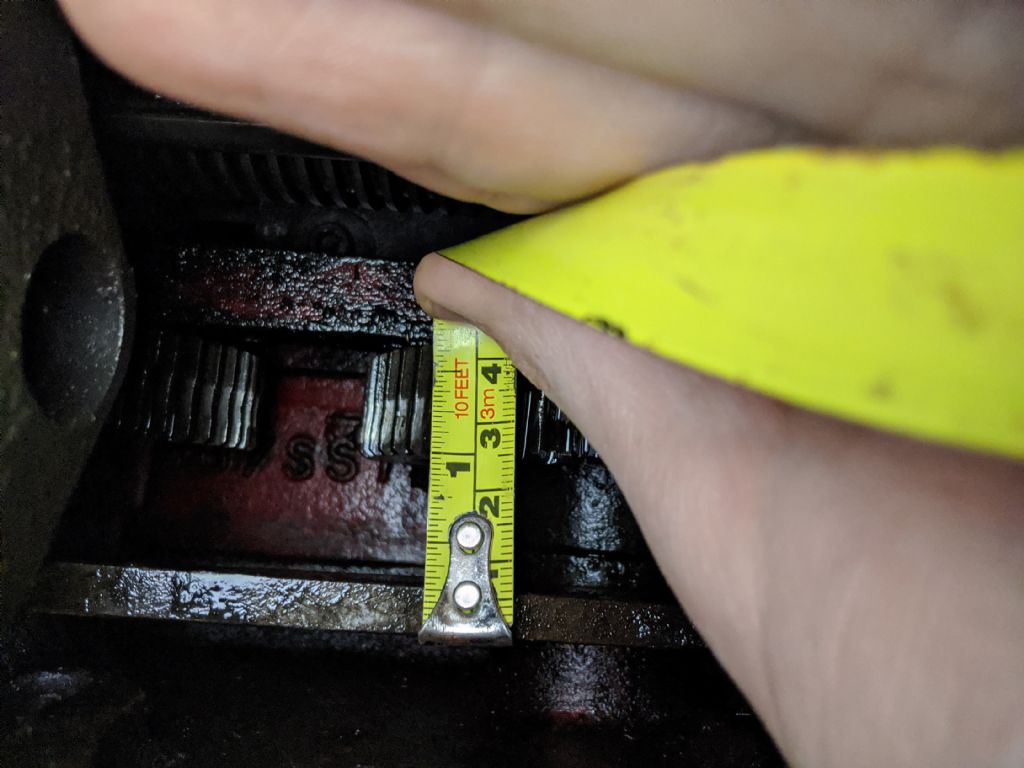

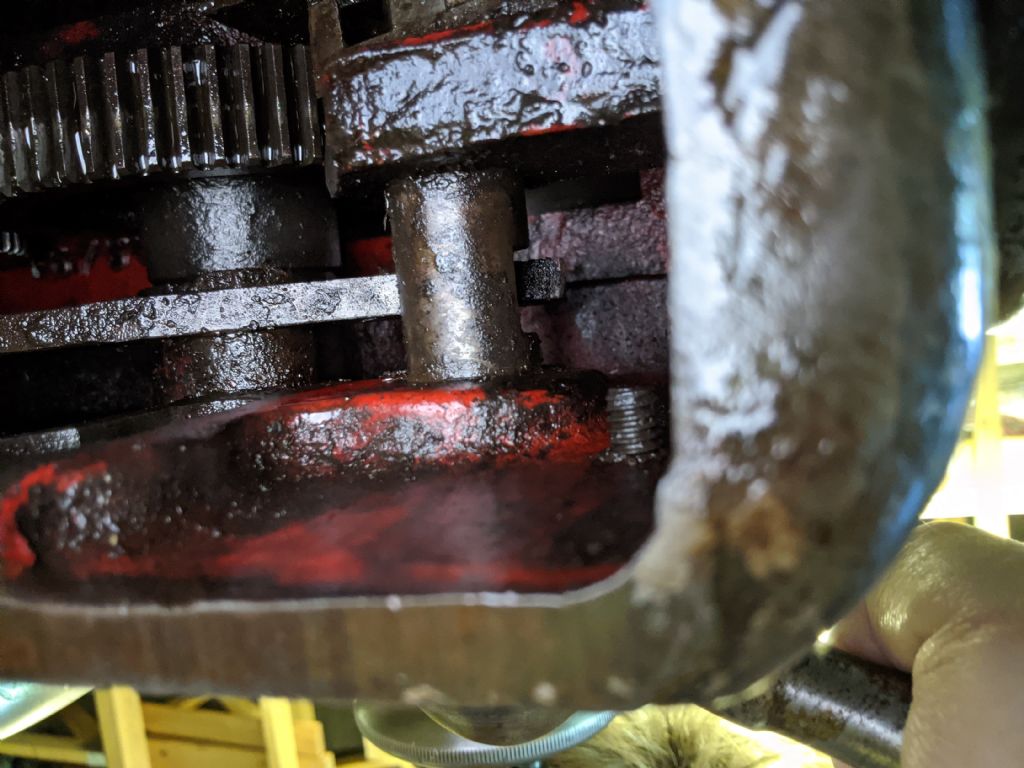

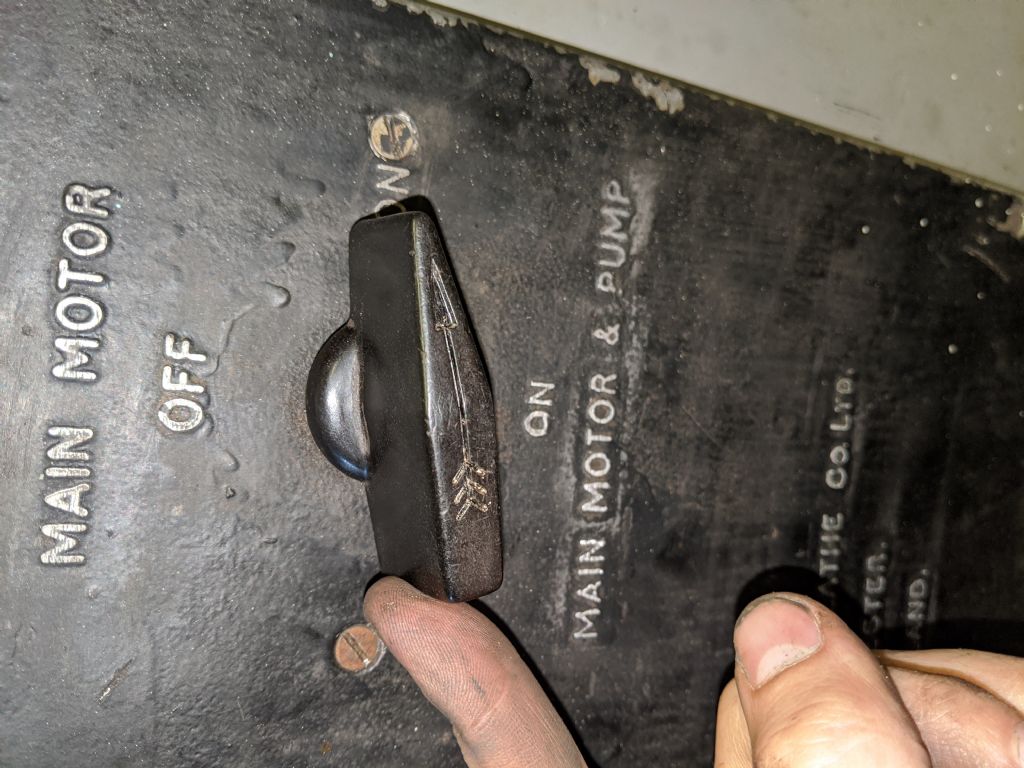

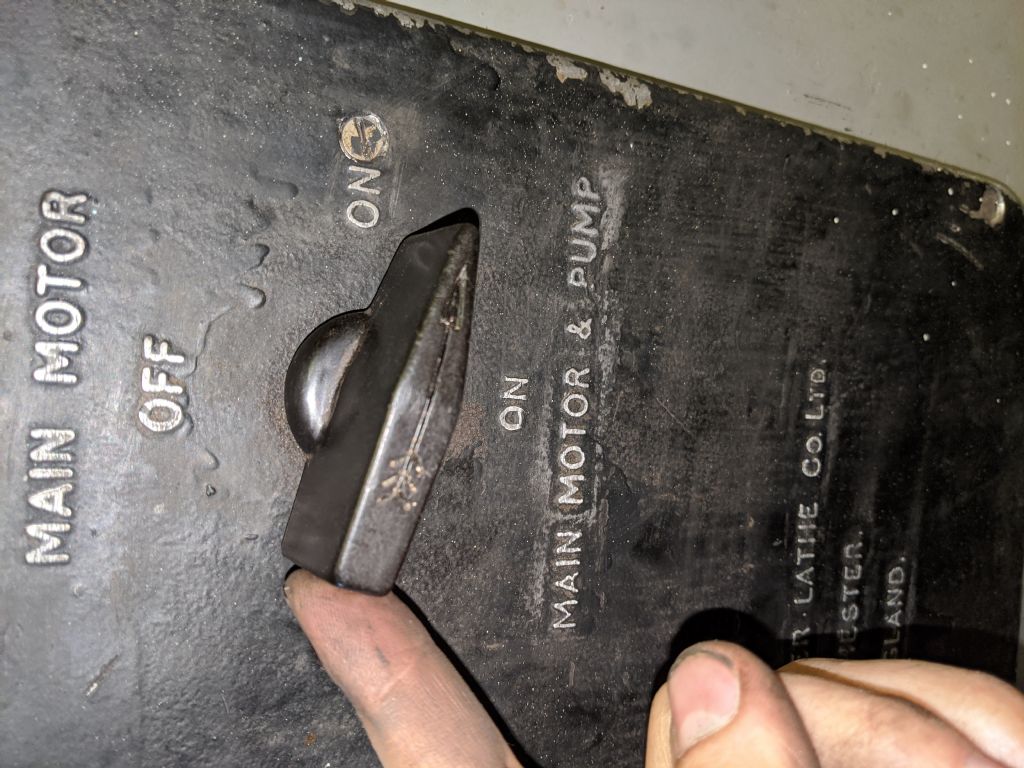

The values of the caps will depend on the type of motor you have installed in the lathe. It looks very old, so I doubt if it is a squarel cage or induction motor.

So you will need to post the specification plates of the lathe motor and the idler motor of your RPC for me.

Then you need to let me know the type of disconnector in the RPC and the specifications thereof.

You will also need to make yourself a cuppa of whatever you drink and trace and draw the RPC's wiring as it is in the big blue box at the moment. In other words you will reverse engineer the existing circuit and produce your own wiring diagram which we can then analyse and check for compliance to your needs.

Lastly the best place to buy your caps would be https://www.surpluscenter.com/Electrical/Capacitors/Motor-Run-Capacitors/ and https://www.surpluscenter.com/Electrical/Capacitors/Motor-Start-Capacitors/ (Not that I know the UK that well, but this is a know source for quality equipment at good prices)

Once we know the details of what we have in place we will have to design the cap values around these. I am very rusted on this as I studied and used this many many moons back when the moon was still blue …

Phil Whitley.