Hello Ramon, (Tug)

It is good to hear from you, and yes it has been a long while now. Jean and I are both OK, being one of the vulnerable ones, we have both been shielding since the end of February last year. Long before we were required too.

We both hope everything is OK with you?

As regards retirement up until this last year in lockdown, I had wondered how I ever found the time to hold a job down. I do however miss not being at the Oncology unit doing my bit, especially now.

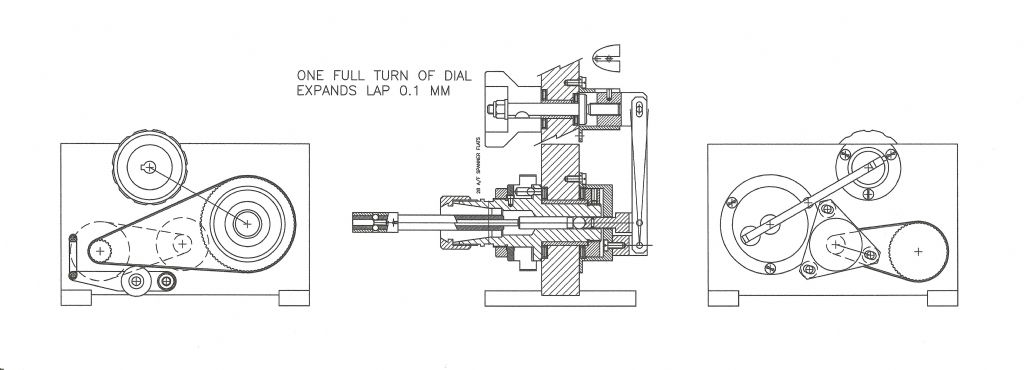

I have to agree with you as regards making the Honing Machine. I have struggled with the actual designing process just because of the current situation, let alone when it comes to actually making the machine. In order to complete another project it would be handy to have this machine. That is all that is spurring me on at the moment, plus I think it would be of benefit to others.

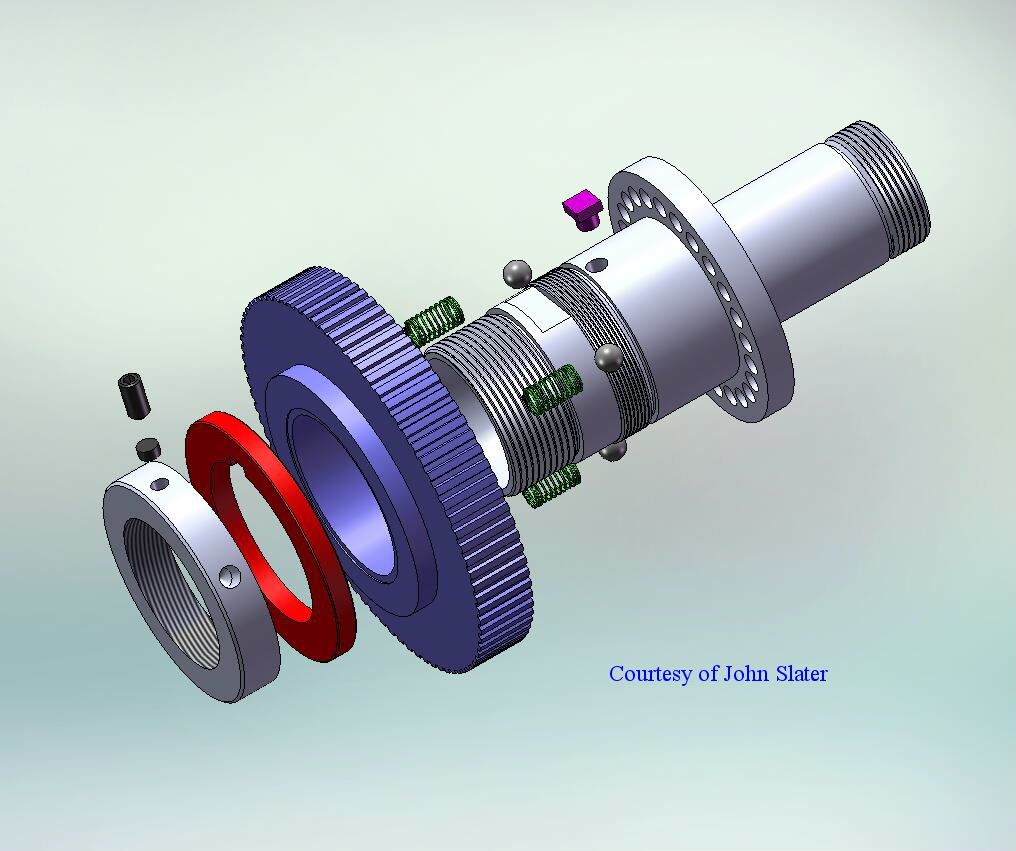

Having the lap larger at the centre is an advantage as it is easier to detect by "feel" if one end of the part is larger than the other. One old Patent sent down by John shows the laps with a very distinct barrel shape in the hole.

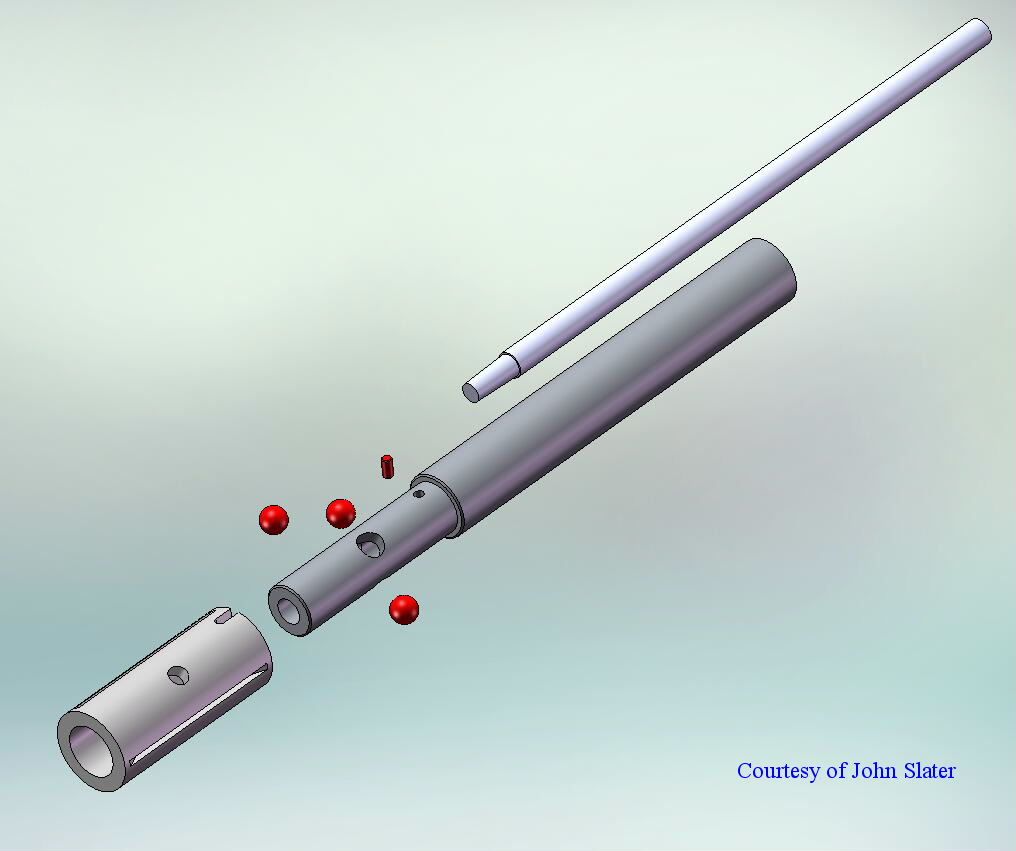

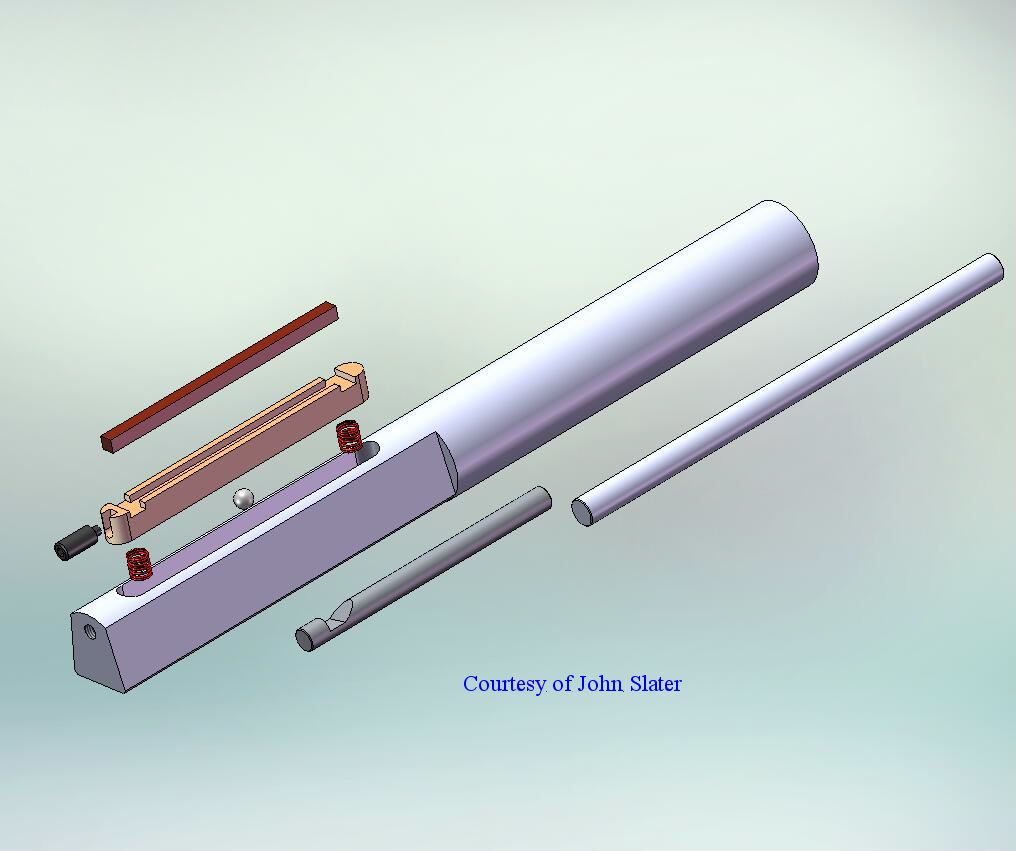

One real problem is trying to lap a blind bore. With this design the adjustment balls can be located almost at the end of the lap. The slits in this case would be open and confined to the end of the sleeve. This would allow the lap chance to lap just on the end. This is something where you are in the "Lap of the Gods" with a parallel lap, (sorry about the pun, it was not intended) .

From using the Sunnen and Delapena machines, honing stones are often manually modified in this way to concentrate the cutting action in one particular area.

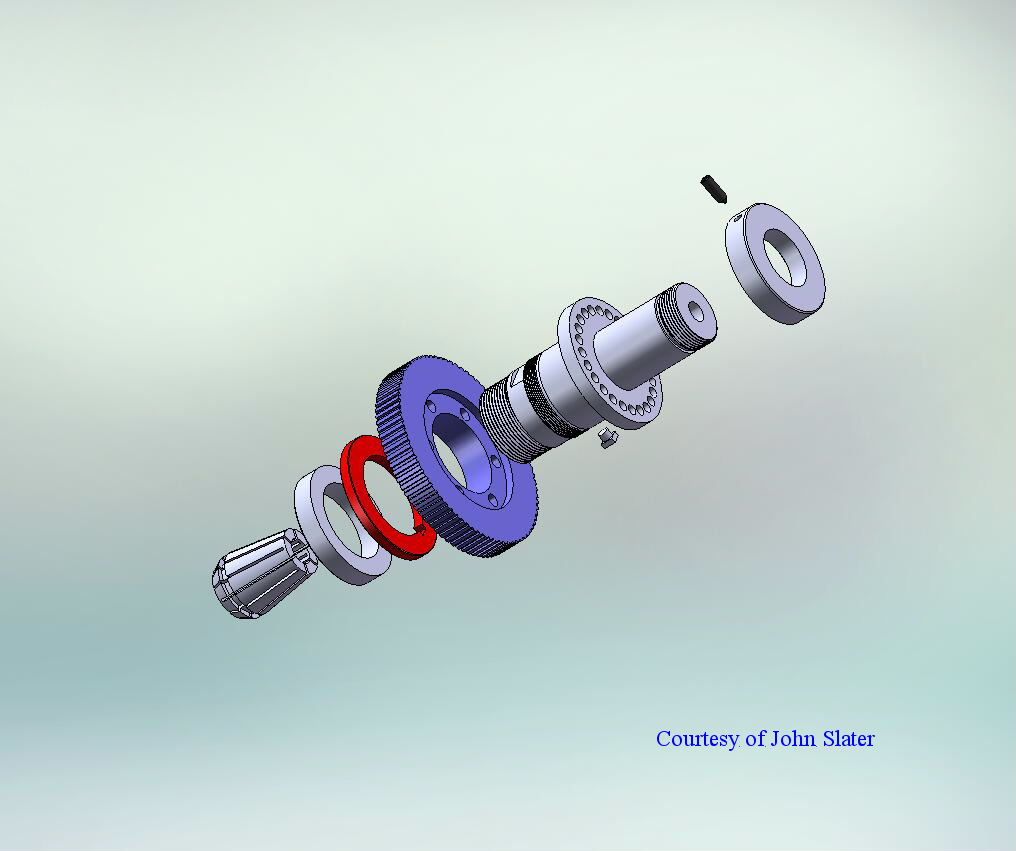

The smallest lap so far designed for this machine, which is still minutely adjustable, is 4.75 mm diameter, this size does not use balls, and again the design can be adapted to do blind bores.

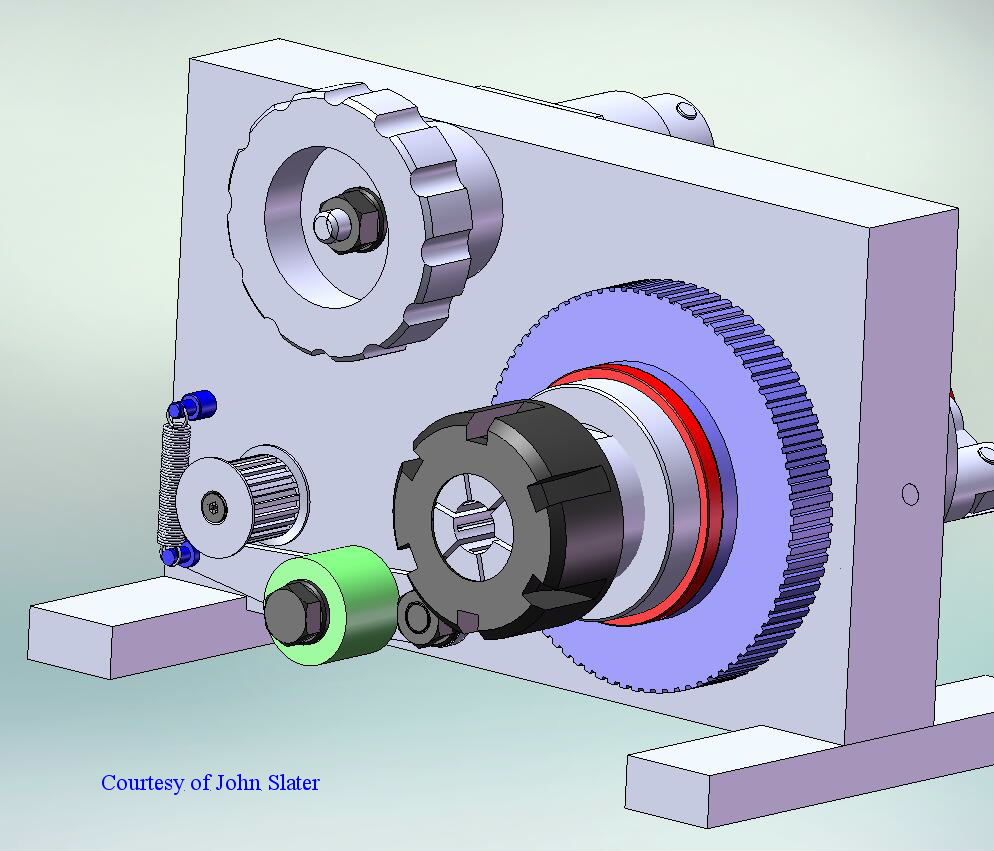

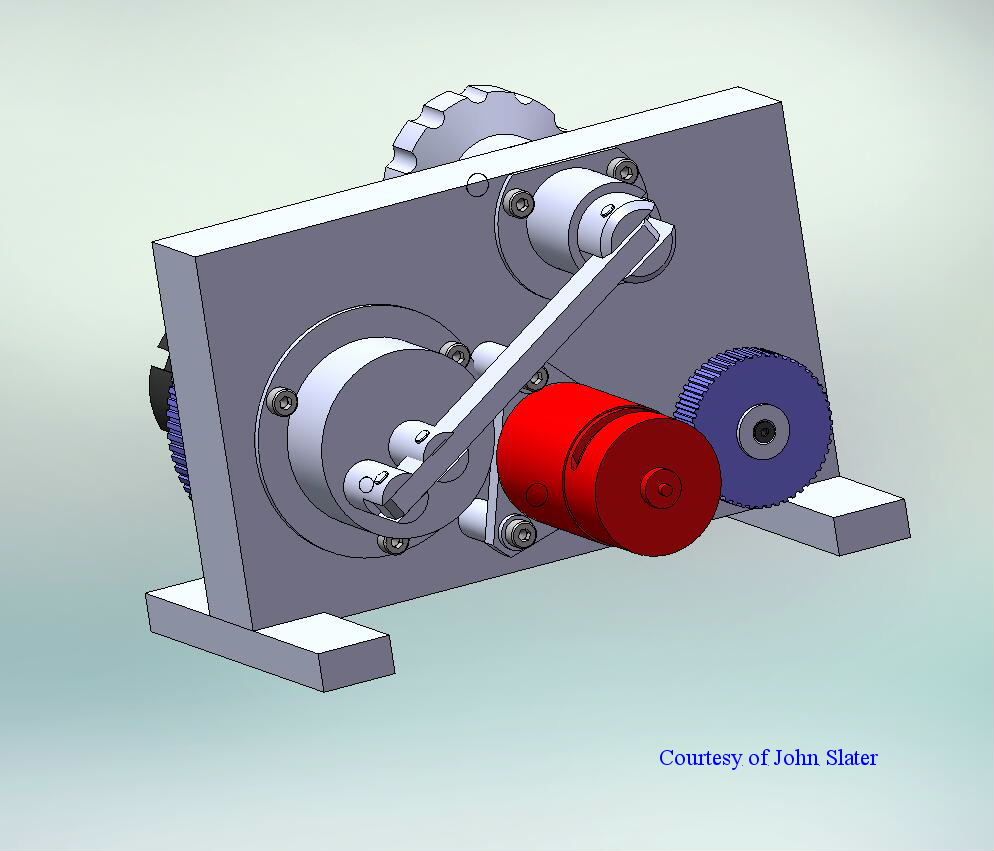

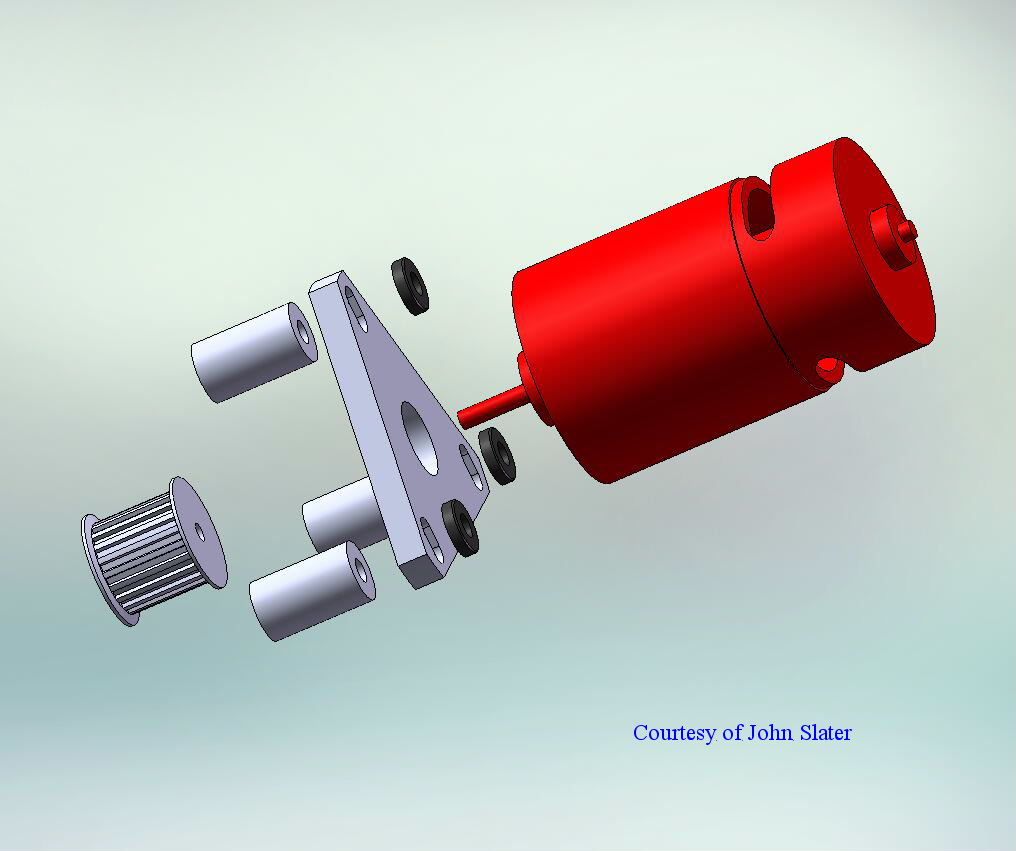

A couple of things I have forgotten to add earlier is the design incorporates an adjustable spring loaded ball clutch, similar to those on a Cordless Drill. This was something John said would be good to have and after thinking about it I had to agree with him. Especially as I would not want to put forward a design which could do someone an injury.

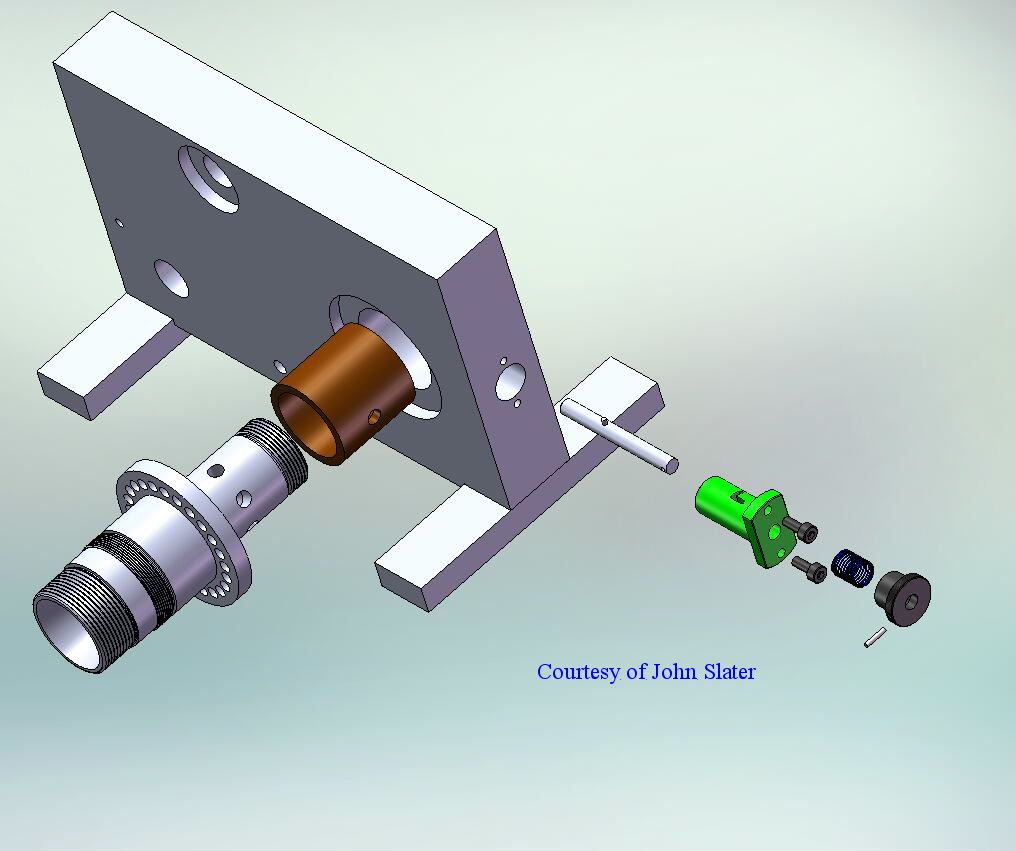

Another feature not shown is a spring loaded Spindle Lock. While a spanner flat is included just behind the collet closing Nut thread. It was decided to offer a hands free lock on the De-Lux model, should any constructor want one.

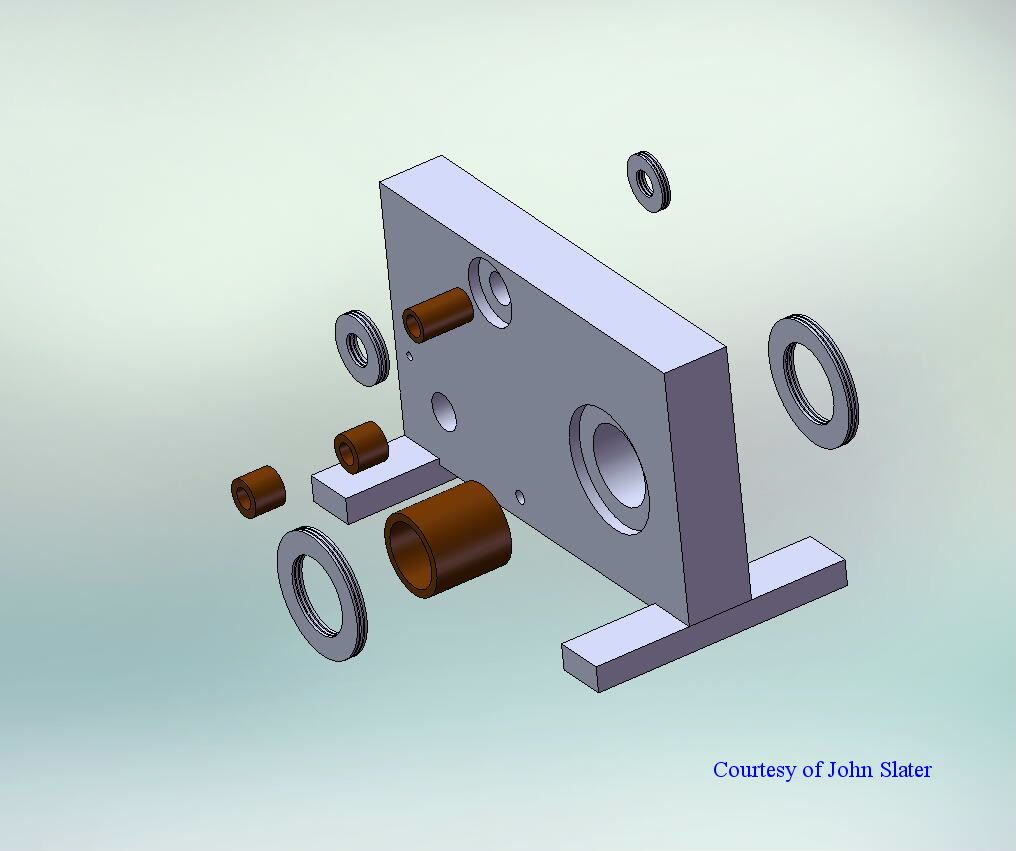

No doubt in due course we will have some 3D views which will explain things better.

Regards

Gray,

Graham Meek.

up to 11.2 mm (7/16"

up to 11.2 mm (7/16"