While the comments on split-dies and splitting solid dies may represent a preference, I don't think that is the answer per-se to the OP's problem. I commonly use solid dies for threads up to larger sizes than 8 mm with no problem at all even on relatively tough material. I feel sure it's not the type of dies that's causing the problem, probably – as others have stated – die quality.

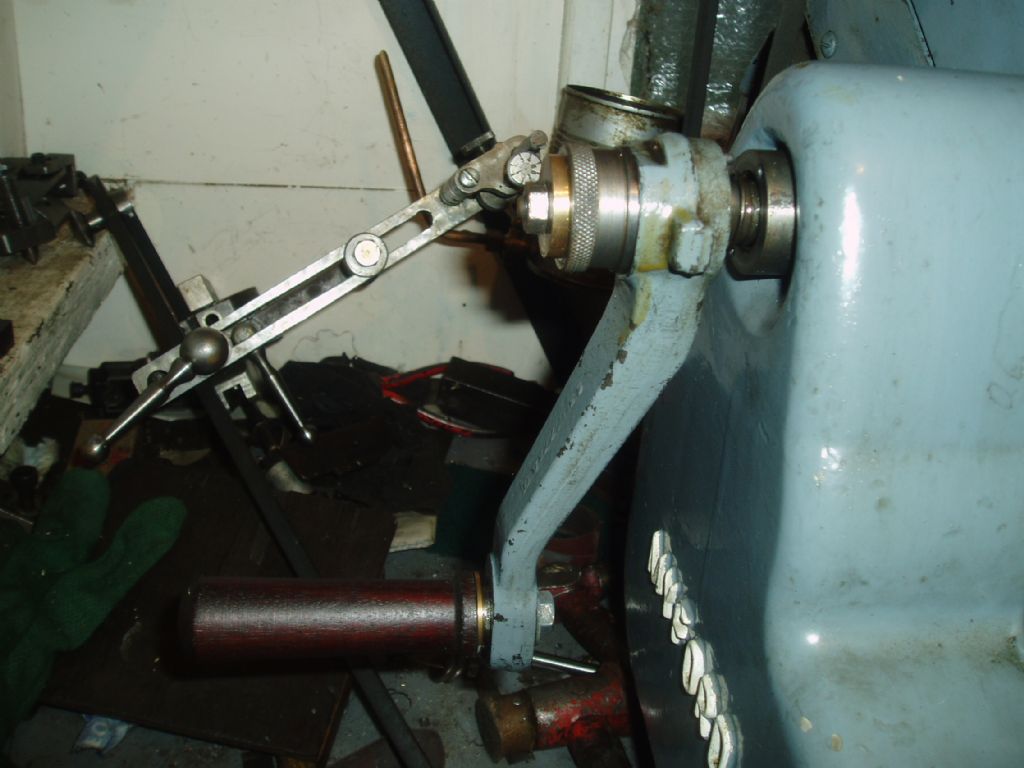

I chamfer the work and do apply support and pressure via the tailstock .A fair pressure is required for starting the thread (but no more than is often used in drilling). I sometimes reduce the work dia a little from nominal but only for "difficult" or very soft materials. Depending on material and size, I can often run the 3-ph controller down to zero, apply pressure with the tailstock and crank up the speed until the work rotates and the die starts to cut.

I was brought up in the UK on split dies and was somewhat perturbed to find them a bit scarce when I moved to Canada. These days, either type are readily available but I've got used to solid dies and actually prefer them except if I'm concerned with thread fit or for unusual conditions. I also prefer split dies if I'm hand threading in the vice. If using split dies make sure the die-holder is a good fit – it's quite easy to break the die if the holder is a bit oversize …. been there, done that.

[I was also brought up in the UK on hand chasing lathe-cut threads. hand chasers are unobtainable here these days (if they ever were)].

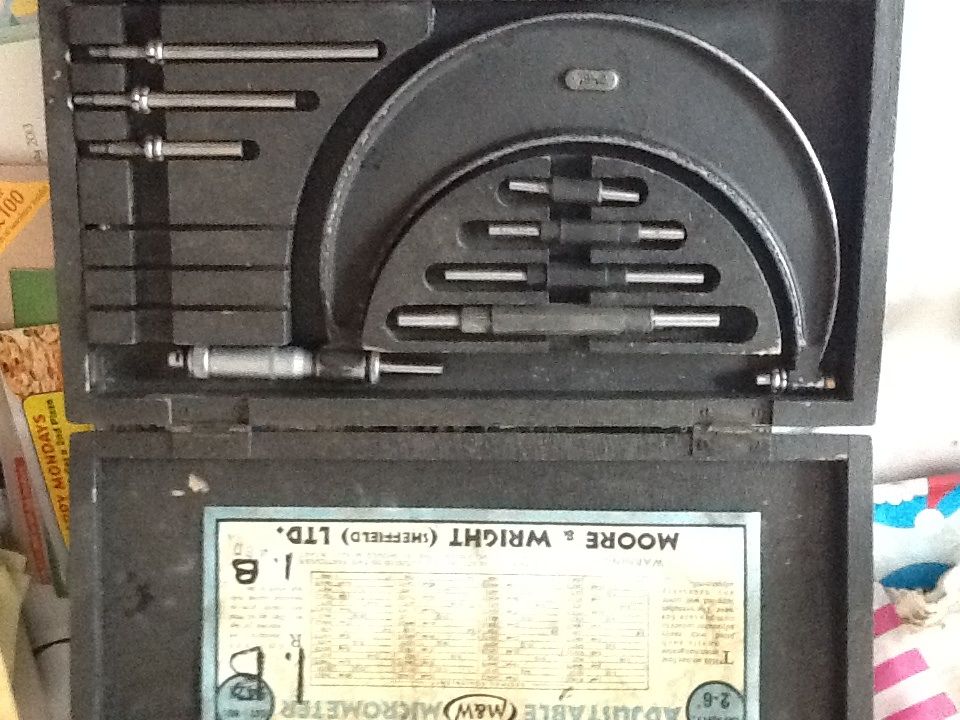

Most of the dies here have a decent lead-in chamfer on one side and virtually none on the other side for threading up to a shoulder.(on a second pass of course)

Edited By Sid Herbage on 05/08/2013 01:36:09

Michael Gilligan.

Michael Gilligan.