Having a breaker bar around and a set of sockets can be useful at times Brian. You may already have a socket set. If you buy a breaker bar look for a very long one.

Parts like these really need making together. Having the holes pre drilled makes things more difficult but does set the centre distance for you.

Given that the holes are there personally I would turn something up that was a close fit in them. Use that in one pair of holes to align them and probably make it long enough to allow it to be held in the drill chuck to align them to that as well. Remove and then ream that hole. Fit a short piece of the final shaft in that hole and then ream the other.

If the drilled holes could be enlarged a touch I would drill before reaming as it will help the reamer produce a more accurate hole. Even when set up like this there will probably still be some miss alignment relative to the holes and drill spindle.

There are all sorts of problems though.

Vice jaws may not be square – the ones you have aren't suitable but it looks like you could make some plain ones for it. Aluminium would be ok. In my view anyway or use steel.

The drill table is probably not square to the drill.

Other than the jaw shape these aren't a problem providing that the shaft holes are parallel to each other which they will be of done in the same setting. They may cause a problem if the little end is a very close fit width wise.

I don't think I would try sticking them together so you could use the ledge on your vice jaws.  Feel free to try it though.

Feel free to try it though.

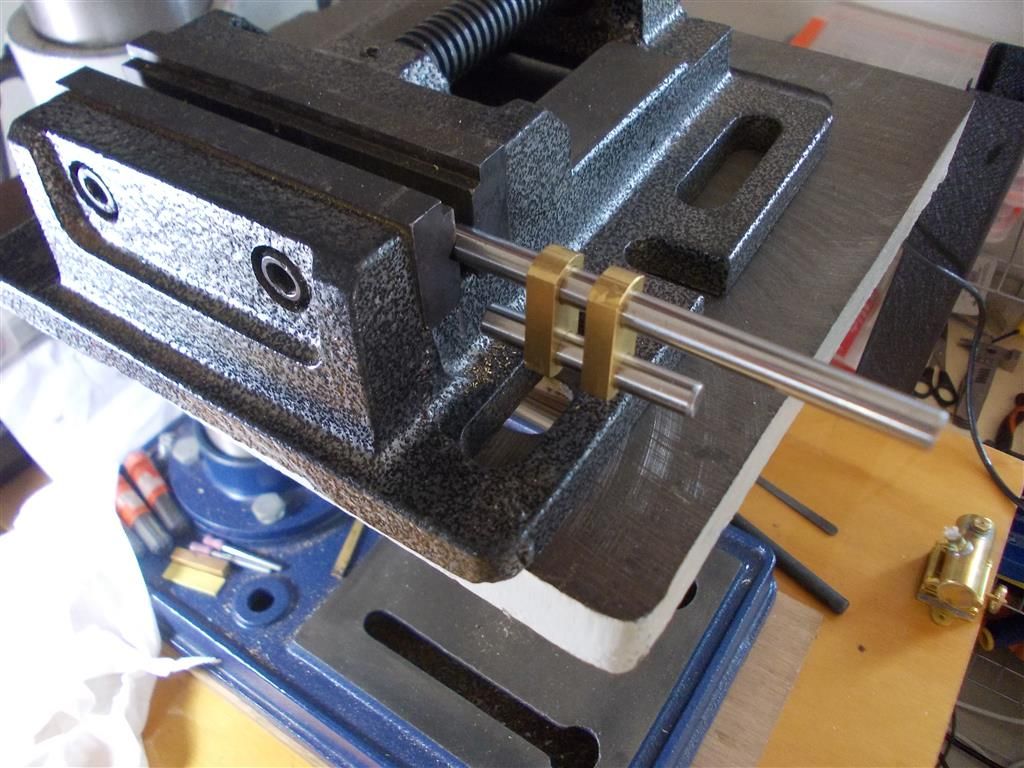

Rather than make new vice jaws you could keep your eye open for vices like this

**LINK**

They generally are dead square all round if used and dated. Some have small V's on one jaw for round work but they are not positioned or sized so that they can't be used for square stuff. I usually drill onto MDF or a bit of scrap aluminium or what ever I can find when drilling straight through in a vice like this. MDF is generally rather flat and parallel over short distances anyway.

As loctite will gap fill a bit you could try aligning the main shaft holes as described and re reaming the little end. Then loctite up while they are both held correctly in a vice.

John

–

Brian John.

Feel free to try it though.

Feel free to try it though.