Andrew

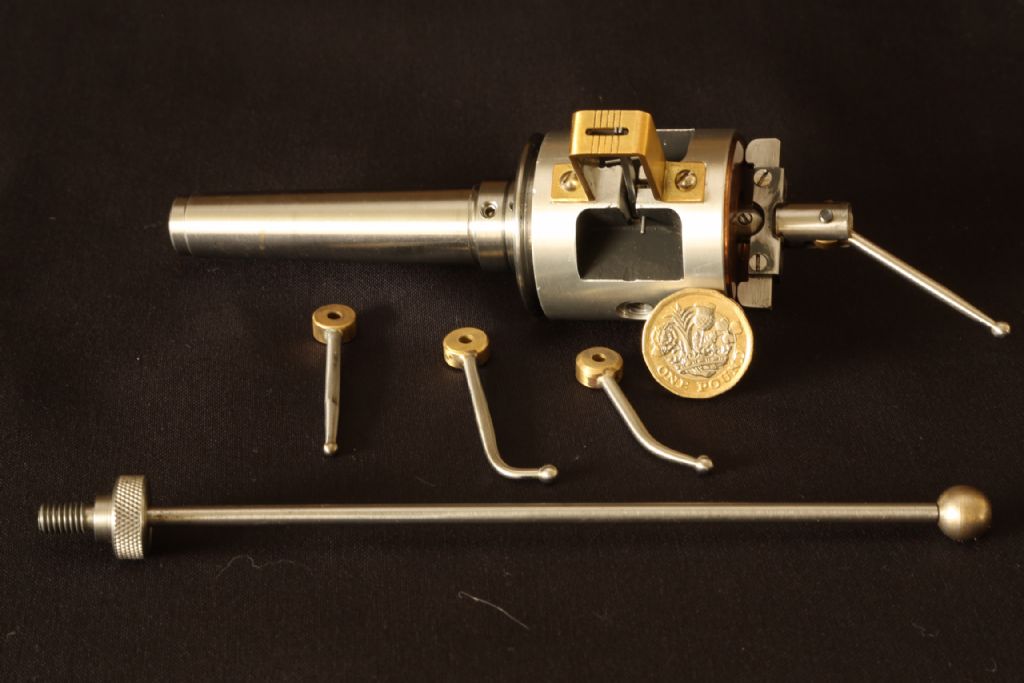

To be fair quoting useful accuracy figures for the typical "Blake knock off" co-axial indicators is difficult because the actual dial calibration depends on the length of the probe fitted and its operating angle relative to the workpiece.

Its non linear too.

Basically just a dial indicator with a double sided rocker drive to change probe tilt variations due to assymetry between workpiece and indicator into vertical displacement that the dial gauge can read.

The Hamier is a seriously different instrument as it actually has measurement capabilities rather than being a pure null indicator.

Blake, who invented the thing, claim 5 thou per division of a 40 division dial when using a 2" long probe with a centering accuracy within 0.0002" for the premium version and 0.001" for the economy one. The website implies that a 0.0005 thou per division dial gauge is fitted. **LINK**.

Out in the real world its easy enough to test by introducing a known sideways displacement after you have it centred and seeing how much the indicator needle displacement varies by. Even centred it seems impossible to avoid a trace of needle flicker even with a very smooth surface.

I went through a test procedure with mine shortly after buying it and concluded "not bad for cheap crap, I can use it." The big imponderable is just how true the rocker pivot rotational axis is relative to the machine axis as any error will induce a constant offset into the centre of the needle flicker range. Mine probably has an error but its manageable with short probes. Long probes have other frustrating issues to work round.

If you concentrate it is possible to get a bore centred under the machine spindle with sufficient accuracy that a test piece made concentric to a spigot and held in a collet needs only to be around 2 thou smaller in diameter to quite easily enter the bore. So ± 1 thou appears possible with mine but its harder work than I'd routinely do. Within 5 thou, not necessarily ± 2.5 (!), is more like it and quick to achieve.

It is what it is.

Apologies for typo in first post using TIR when its not really appropriate. Thinking of indicator needle movement without factoring in probe length.

Clive

Edited By Clive Foster on 30/11/2020 22:09:12

Oily Rag.