Hi Piero, I think the best answer to your question about where do the bits fit is to suggest you need a copy of Brian Wood's book, Gearing of Lathes for Screwcutting, which gives chapter and verse on the subject. ARC have copies, and so did Amazon the last time I looked.

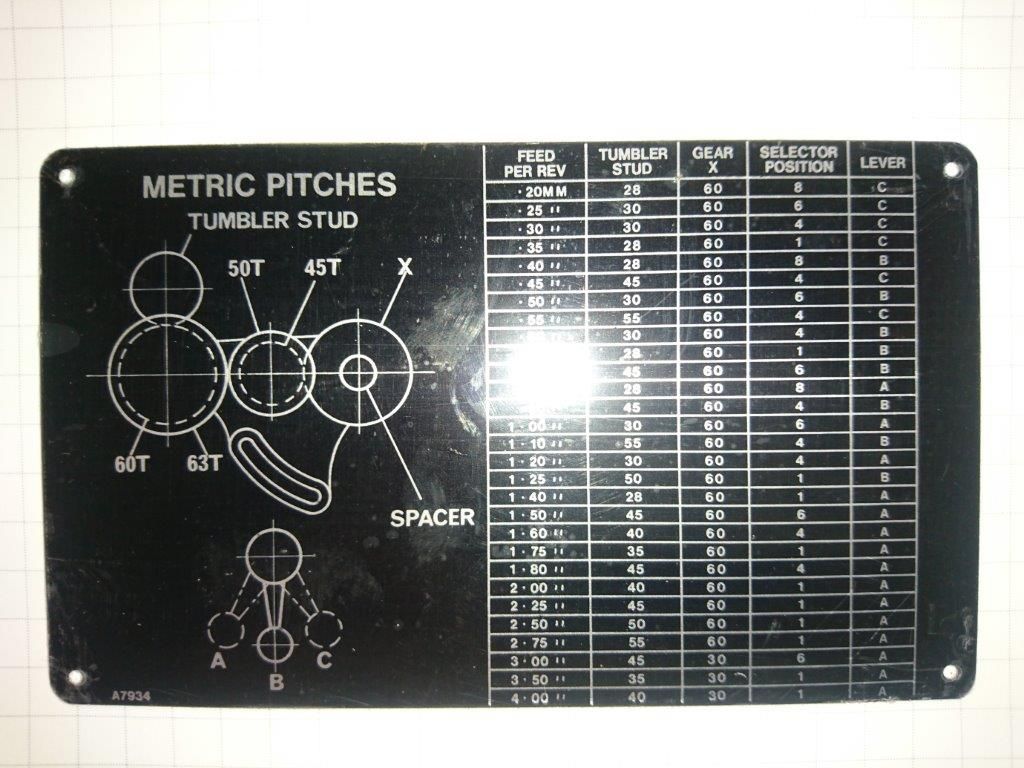

Essentially the gear train that carries the drive from the lathe mandrel down to the gearbox input gear is removed, and replaced with a selection of gears of different tooth numbers, all as per the appropriate label as above.

The standard banjo on which the gears are mounted isn't slotted, so this limits you to only using the original gears. To be able to use others (as per the label) you need the gears AND a different banjo. The one that Myfords sell, and which has been called the "Metric Conversion Kit", fits in place of the standard gear mounting carrier and allows change wheel trains to be built up in much the same way as you would in the old days before the quick change gearbox was invented. The difference here is that the slotted "Metric conversion kit" banjo lets you keep the quick change gearbox AND change the input ratios. That's what the labels above are showing.

The other half of the metric adaptor kit is a selection of change wheels of some funny looking numbers, as detailed on the labels above. If you would like to list the wheels you've got lurking in a box we can tell you what you can do with them, and whether they belong as a set with the metric conversion kit. (And for which version of the Q/C gearbox!)

Brian's book explains in more detail.

Myford users being inventive so – and – so's, along came the idea of keeping the original fixed spacing gear carrier, and changing the input gear (mandrel gear) to adapt the ratio between the mandrel and the lead screw. It happens that an extremely close approximation to the "correct" ratios can be achieved for a wide range of metric pitches just with a small handful of input gears. For the later gearbox, most of the metric pitches you'd likely want are achieved with a 33T and a 34 tooth gear, mounted on the 10351 tumbler adaptor as detailed above. John Stevenson pioneered this, and the gears to do it need are available from Myford. But it doesn't work for you and me – read on.

The big advantage of this technique is that you get to keep the fine feed ratios. If you fit the "metric kit" you lose the facility of the fine feed. The metric pitches you get are an approximation to the "true" metric pitches, but that's also true of the pitches you get with Myford's metric adaptor kit. Some of the approximate results are actually better than the original design, and (as Brian's book examines) you need to consider the limitations of the lathe's accuracy as well.

For your lathe – and mine – this doesn't work, as the early gearbox does not have the built in 2:1 speed reduction of the later gearbox, so if you set up the gear train as for the later box you cut a thread of twice the pitch you expect.

All is not lost, we know how to fix it. If you want to get involved with this we can explain further, but you really need to see Brian's pictorial explanation of what is going on first, as the adaptations to make it work with your earlier gear box assume an understanding of the overall system and also some rather creative gear cutting which John Stevenson devised.

Hope this makes sense,

Rgds Simon

Piero Franchi.