@Marcus: Michael is correct, it's just the colour balance that is off (I took the photo under my desklamp, which has a tungsten bulb). The bolt is most definitely steel.

@Neil & @mechman48: You are both right, the beefy leaf spring (350mm long, 35mm wide, 3mm thick) is there to hold the blade firmly against the shearing edge on the platform. Again, the angle of the blade is the critical paramater; if it doesn't pass the edge at exactly 90&#deg; the paper will be sqeezed and folded instead of neatly cut (and angle it the other way and it will hit the platform!). So the bolt has three jobs: 1) to give the blade a point to swivel around 2) to keep the blade laterally in position 3) to maintain the correct blade angle. Radial position is not critical; a small amount of radial movement won't affect the cutting action.

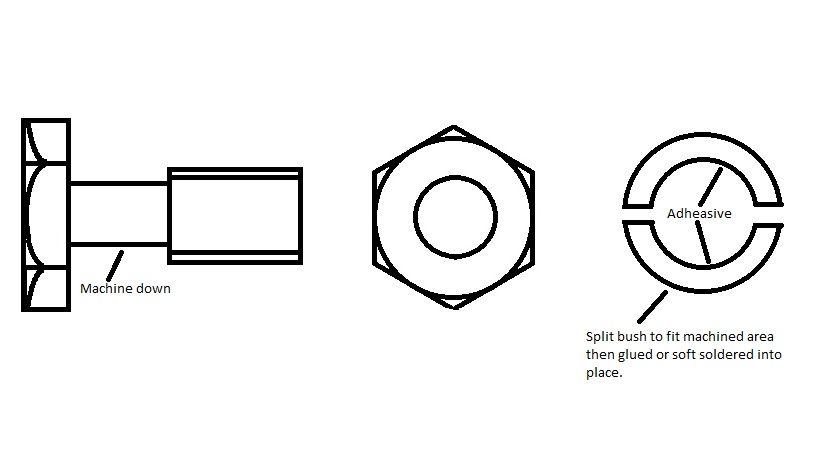

Now the main problem with the worn bolt is that the head has been thinned on one side from friction against the leaf spring – this means it is unable to force the end of the spring flat, which severly reduces the amount of pressure the spring exerts on the other end. The base of the spring needs to be forced flat against the bearing sleeve on the blade to do its job properly. If I was to reuse the bolt I would have to find some way to make the underside of the head flat, but I only have a small bench grinder and an angle grinder – I doubt I would be able to get a satisfactory result with either!

@Bodgit: Thanks for the suggestion, but I don't have oxy/acetylene gear, just a small propane torch, so I don't think I can braze steel. Even if I could, I don't have a lathe either, so wouldn't be able to turn the bolt afterwards.

@Chris: Many thanks for looking – I suspect you may be right about 1/2" bolts not being 1/2" at the shoulder. A brass bushing would be ideal, but I would have to enlarge the hole in the blade's mounting sleeve, which I don't think I can do. A very thin shimming tube that is slit open might be the best option, but again I do not know where I might find such a thing!

@Keith: Hehe, yeah, that's a typo, and I did search for "Whitworth". You and many others have suggested contacting "a professional bolt supplier" – indeed that was exactly why I posted my question here; to get some suggestions on "professional bolt suppliers". You make it sound easy to find one, but it hasn't proved all that easy to me! The 1/2" bolts from Cromwell tools look great, but unfortunately they have BSF fine thread which won't fit. They are also a tad pricey @ £12 each, but that would have been acceptable if only it would fit!

Thanks again to everyone for your kind help!

Russell Eberhardt.

Russell Eberhardt.

The bolt is a 1/2" diameter, with a 1" threaded section, probably UNC, possibly BSW(?). Since it acts as the hinge for the blade it needs to have a smooth shoulder (also 1/2" dia) and be made from some wear resistant alloy. Here are a few photos:

The bolt is a 1/2" diameter, with a 1" threaded section, probably UNC, possibly BSW(?). Since it acts as the hinge for the blade it needs to have a smooth shoulder (also 1/2" dia) and be made from some wear resistant alloy. Here are a few photos:

I should get a set of gauges really; this isn't the first time I've been confused over a thread! Thanks for your suggestions, and for pointing me in the right direction, thread wise.

I should get a set of gauges really; this isn't the first time I've been confused over a thread! Thanks for your suggestions, and for pointing me in the right direction, thread wise.