Gentlemen (ladies?), my first post here so please make allowances.

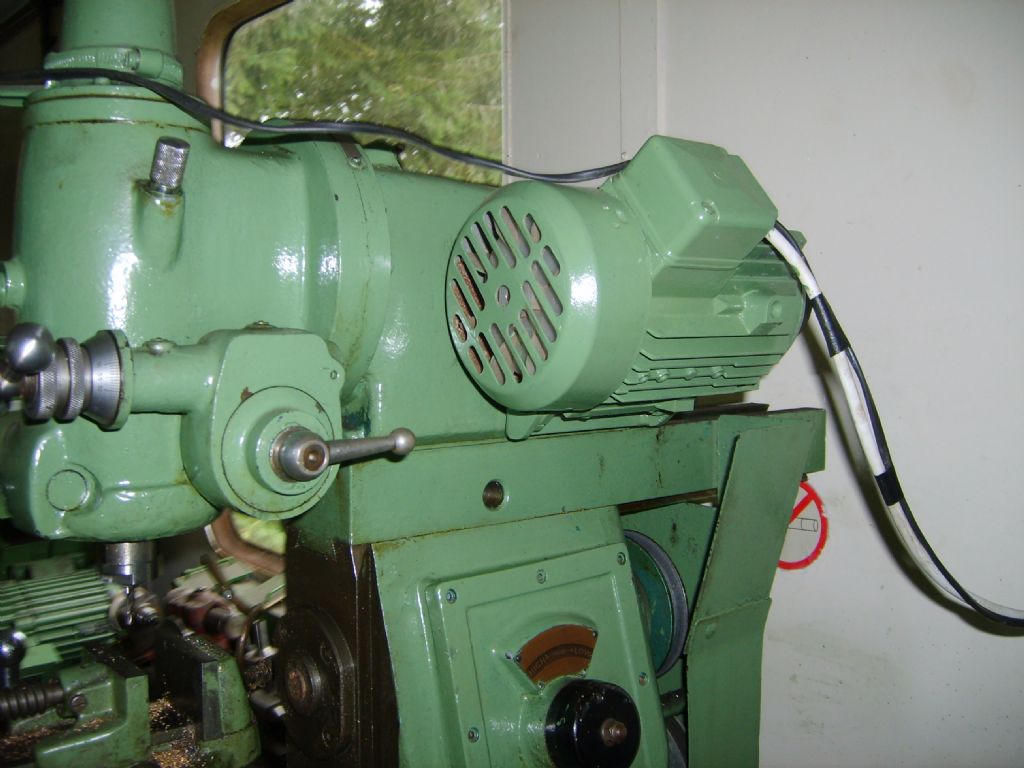

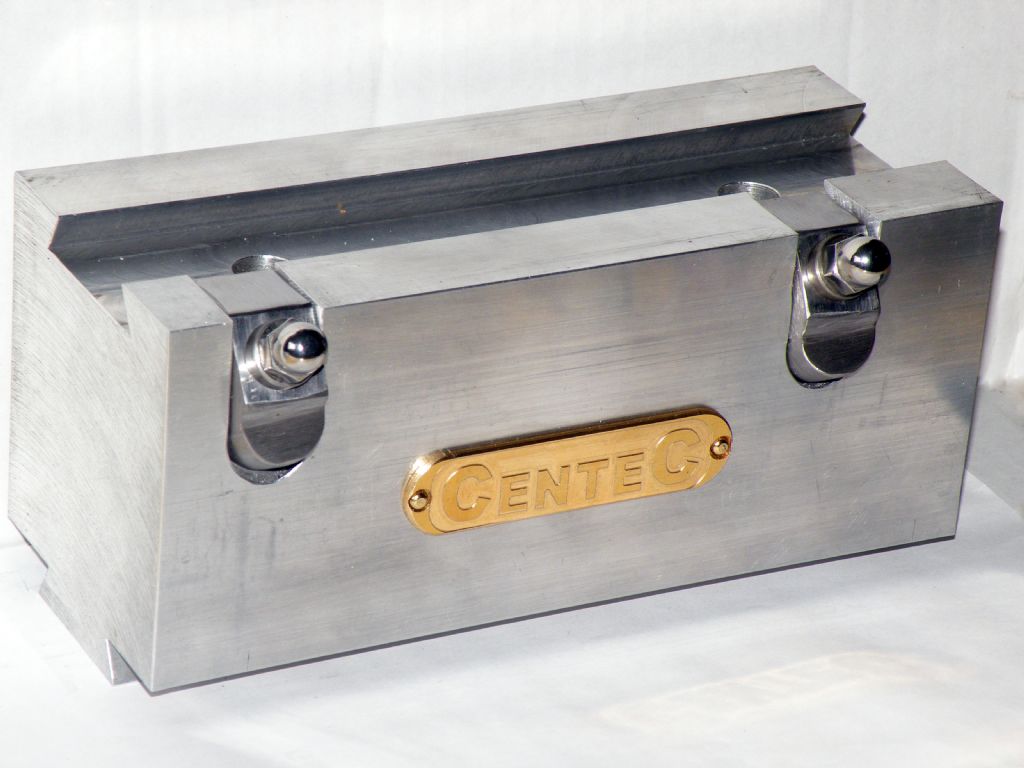

I am the fortunate owner of a Centec 2b milling machine with mk3 vertical head. I would like to add a raising block,not so much to increase capacity as to avoid the daunting job of lifting the head on and off. A member on this site kindly showed pictures of some he used to make but said firmly that he wouldn’t be making any more and Tony Griffiths(lathes.co.uk) hasn’t got any in stock and is unsure whether he will again.In any case I can ill afford the £340 or so required for something that will be used only now and then.

So my next thought was to make one myself,either from a block of ‘continuously cast’ iron or by making a cored pattern and getting it cast(I’m more experienced with wood than with metal).Either way it means a big lump of iron.

So…plan C. The existing overarm is redundant as soon as the raising block exists. It already has one of the dovetails and most of the bulk required and my idea is to cut the top off it like a boiled egg-along the top off the Centec name panel probably- and graft a piece on top in which to mill the top dovetail. I think that with care it could be done without looking too bad.

My questions then are:

Will it work?

Will the overarm casting distort and become useless as soon as it’s cut. It’s 50-60 years old so ‘seasoned’ and I wouldn’t be cutting that much of it away.

The idea is to hold the parts together with Epoxy and screws from underneath,would filling the hollow section with,say,epoxy concrete be a good plan.?

Anyone know a helpful foundry?, I live in North Wales.

And finally,is it a sin to butcher a good bit of old British engineering like this.?

All advice and opinions gratefully received.

Brian H.