I did two things today. I cut some new nameplates for my freelance 5" gauge 0-4-0 because the ones I did before looked far too big when I went to put them on. Should have printed them out for a trial but I didn't have to loco home until last weekend.

The new nameplates gave me a chance to try holding the brass down on the MDF with masking tape and superglue. It worked well and held the brass flat. The superglue let go in a few places allowing a small amount of lift. On one plate this wasn't significant because it was off the end of the job and on the other I noticed it before I started so flooded some more glue in there and weighed it down for about 20 mins. I noticed a small unmachined fragment in the lower void of the 'E' after a coat of black paint so that needs cutting down manually later once the paint dries.

There was one exciting moment when I went to profile around the outside of the plate and forgot to change Cut2D's default feed units of mm/sec to mm/min! I'm assuming the table moved at it's max rate but the 2mm cutter didn't break… I was equally relieved and impressed. The finish was rubbish though.

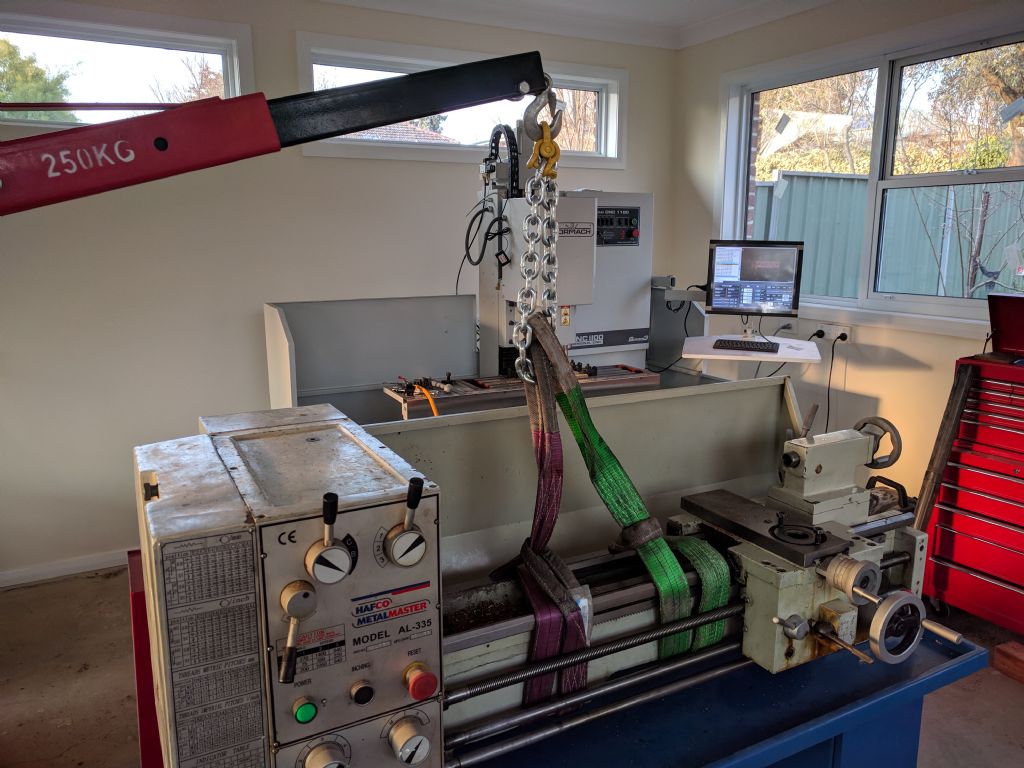

The other thing I did was move the lathe off the wooden blocks and further away from the mill to re-open the passage between the two so I can get around them easily. The move went without incident this time. The lathe is still a bit unsteady at the tailstock end so that part of the stand is obviously not much good. When it was on the blocks I could just move one of the two tailstock end blocks by hand with no resistance.

I think some adjustable feet might be a project in the near future unless the batch of brake parts I make on it soon come out ok, in which case I'll leave it alone. I really hate working on the machines or tooling rather than the project or loco I'm trying to build.

That was actually all yesterday. Today I am going to fix that little unmachined bit on the nameplates, fix a piece of plywood to the bottom of a tool cabinet that is of such appalling quality the castors screws simply pulled out while moving it around (don't but tool cabinets via eBay!), and perhaps making a start on the CAM for the weight reduction pocketing of the sandboxes I made last week. It would be quicker to do it manually but I need to learn to use my new machine for something other than faux-cast plaques.

David.

Tim Taylor 2.