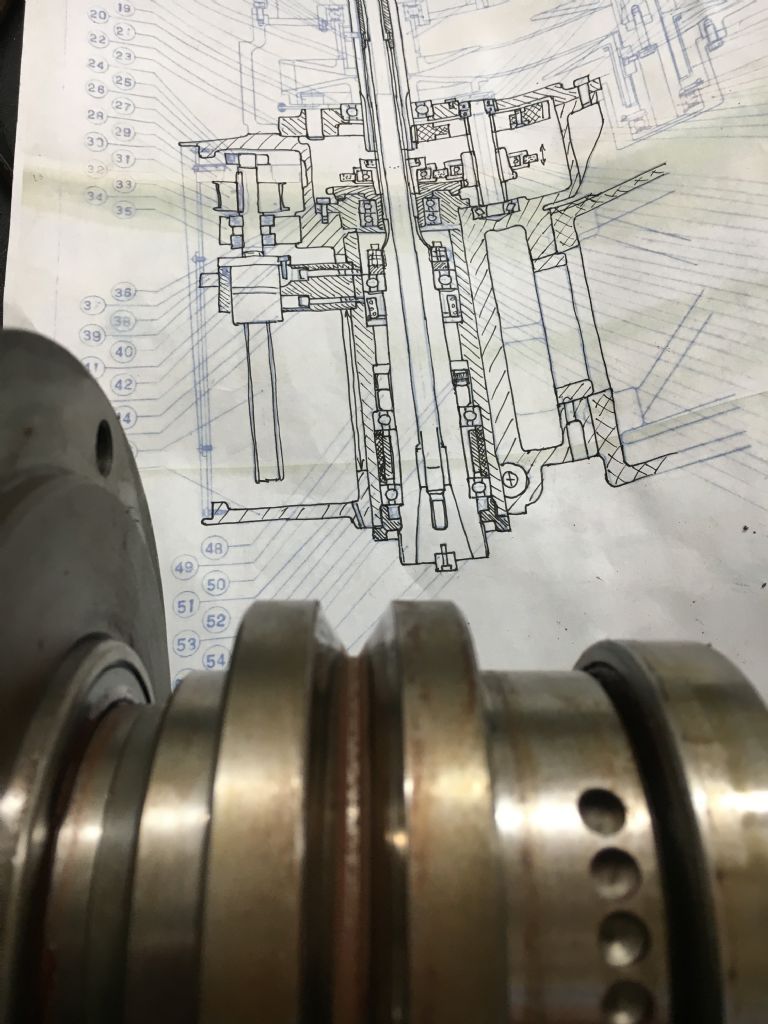

I finally got irked enough by the strange graunchy noise coming from the spindle of my CNC machine to actually do something about it. It's clearly not coming from the actual spindle bearings themselves, yet doesn't sound like the sort of noise motor bearings could make either. Have a listen here. The only way to fix it is to remove the motor and belt housing to have a closer look. There are other benefits to doing so: the belt looks as if it's not long for this world, the back gear assembly is one area I haven't overhauled and I would like to fit a shaft encoder to the spindle so that I can do rigid tapping at some point. Finally, there will come a point soon when I will need to extract the machine from the workshop through the roller doors that are only 7' high. This will require me to remove the motor / drawbar / belt housing etc, so it would be sensible to have a dry run up front. The workshop was built around the machine, so getting it in wasn't a problem.

The main issue is that the motor is big and heavy (50kg?) and is over 2m from ground level. And the belt housing isn't a lot smaller or lighter, being a large cast iron jobby.

Managed to extend the boom of the engine crane sufficiently to reach above the motor and bring it down in a controlled(!) fashion. Ditto the housing. No death, hospital visits or changes of underwear were required.

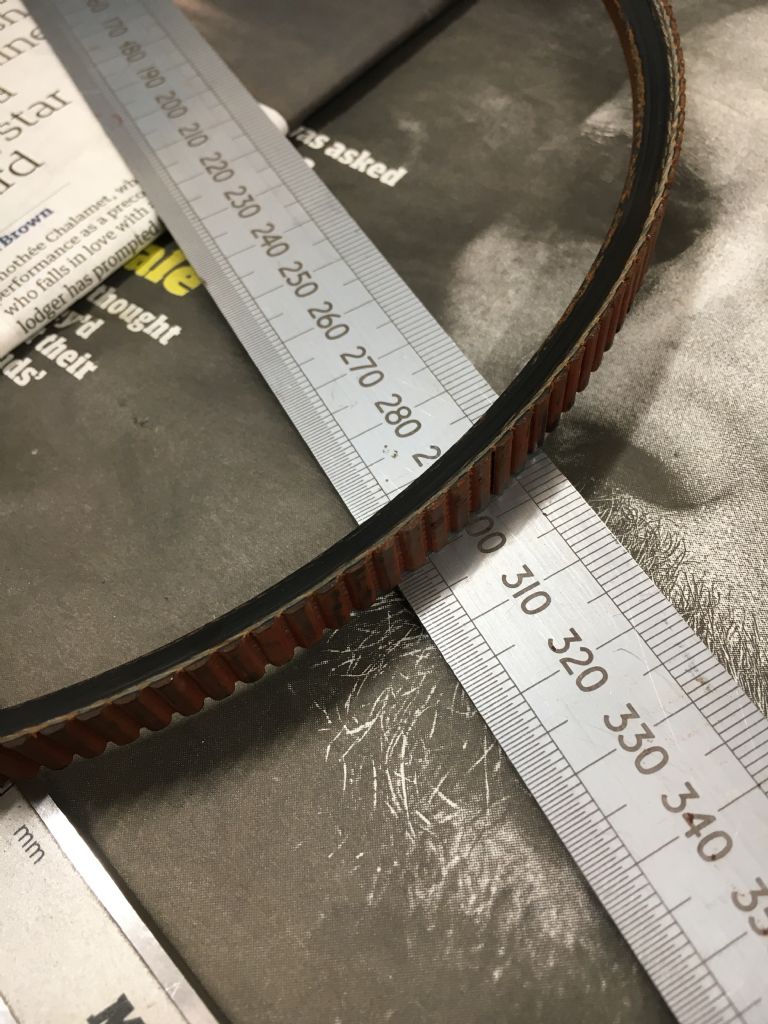

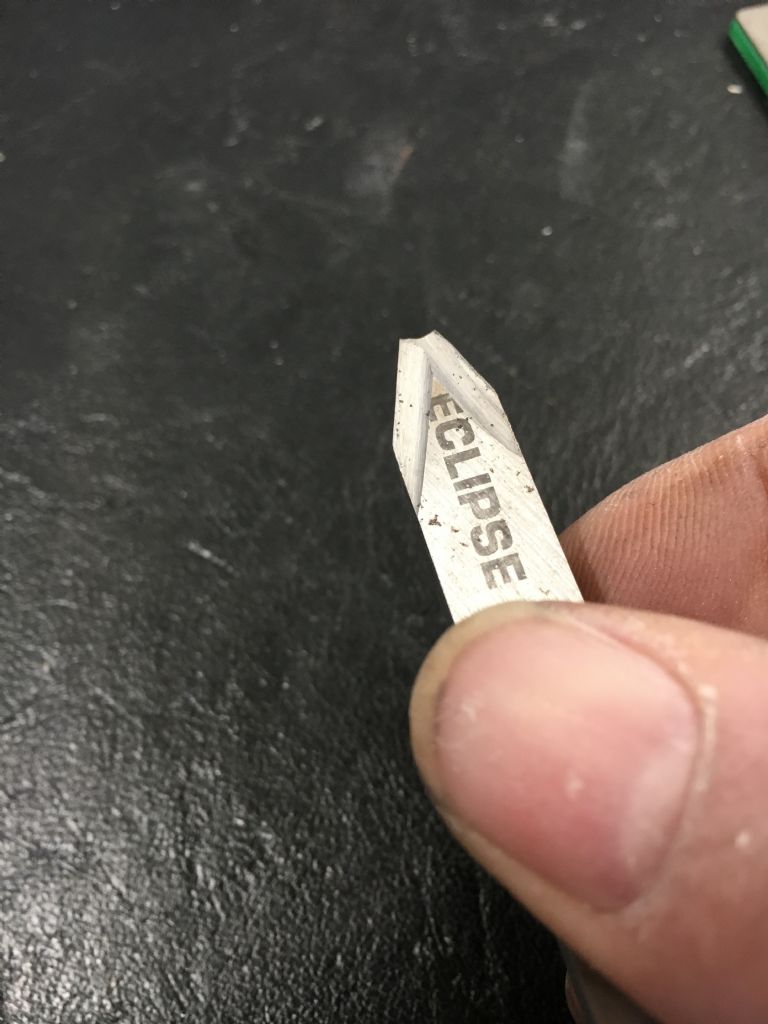

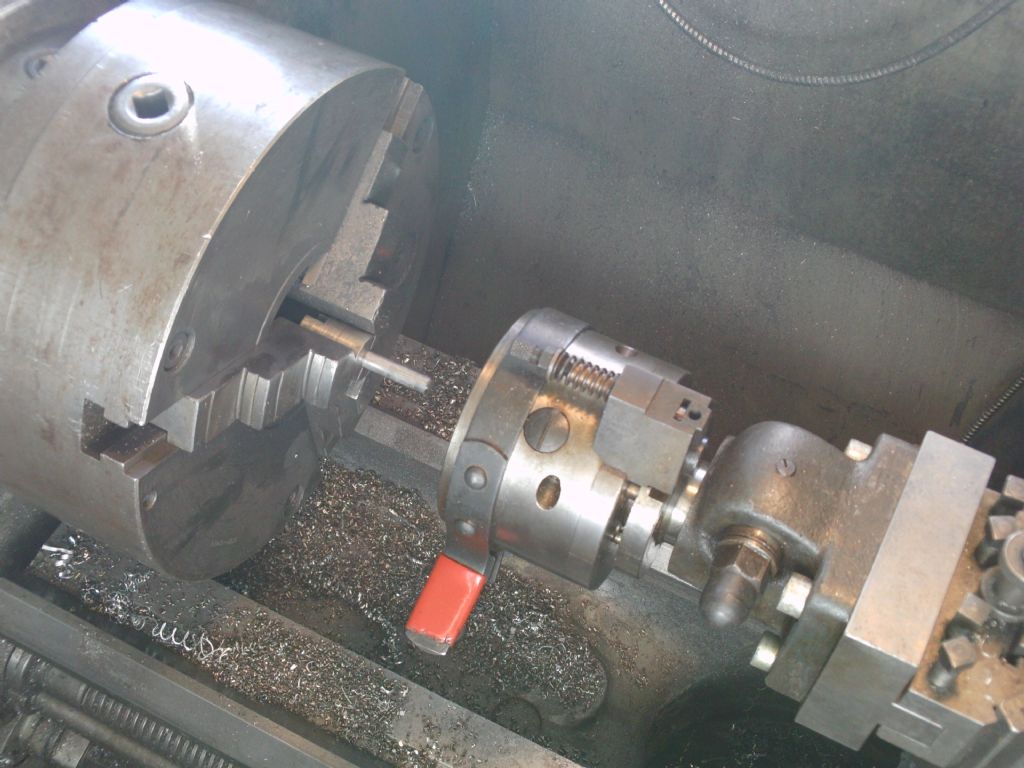

It's now clear that the funny noise was due to the perished belt which is hard and shiny in places. But what surprises me is that it has 60 degree faces on the vees. It measures about 11mm across the top of the vees. Has anyone seen 60 degree vee belts before? It's a new one on me. Having said that, the motor and spindle pulleys are clearly worn in places, so I may as well remachine them to a 60 degree profile.

The next step is to remove a couple of kg of heavy grease from the gear chamber, then degrease everything, check bearings, regrease and reassemble. Before regreasing, i will fit a couple of proximity sensors next to the main spindle gear. By placing these apart by 1/4 of the pitch of a tooth I should get a quadrature signal that indicates spindle direction as well as speed.

Murray

Edited By Muzzer on 08/01/2018 18:50:32

Tim Taylor 2.