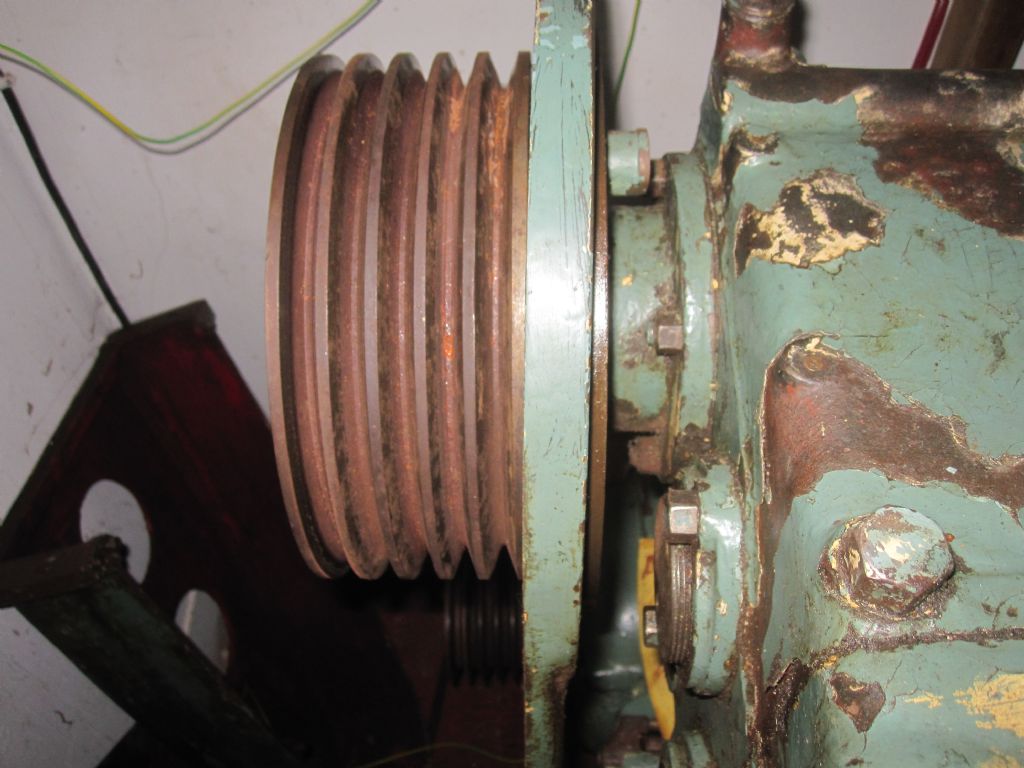

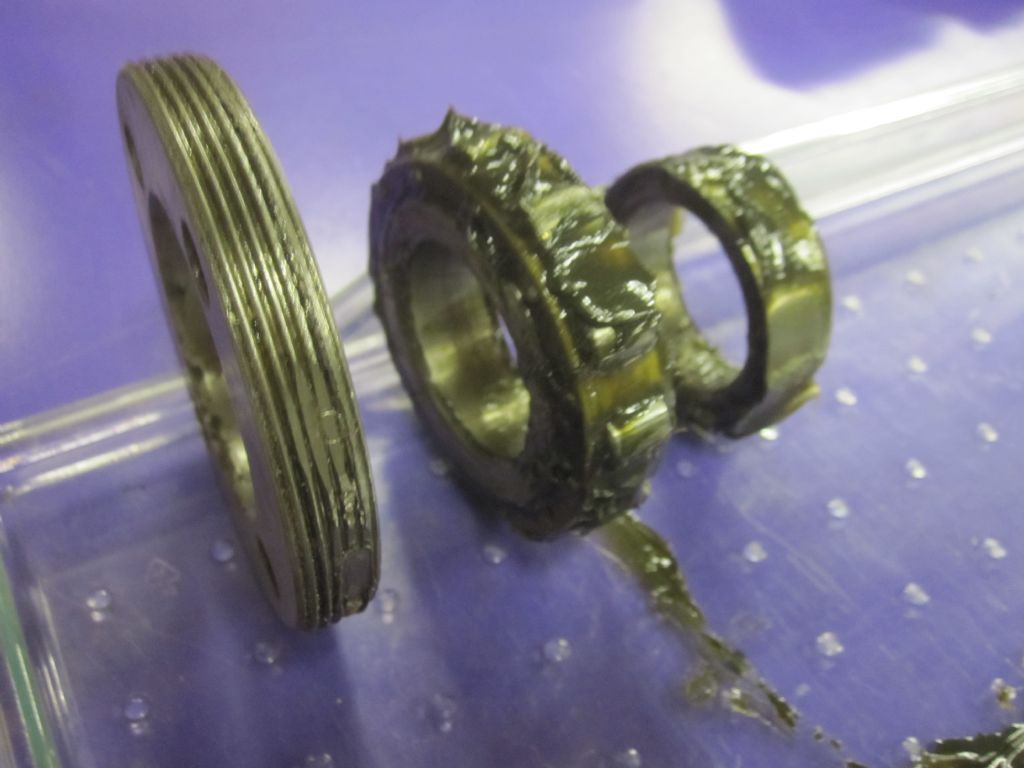

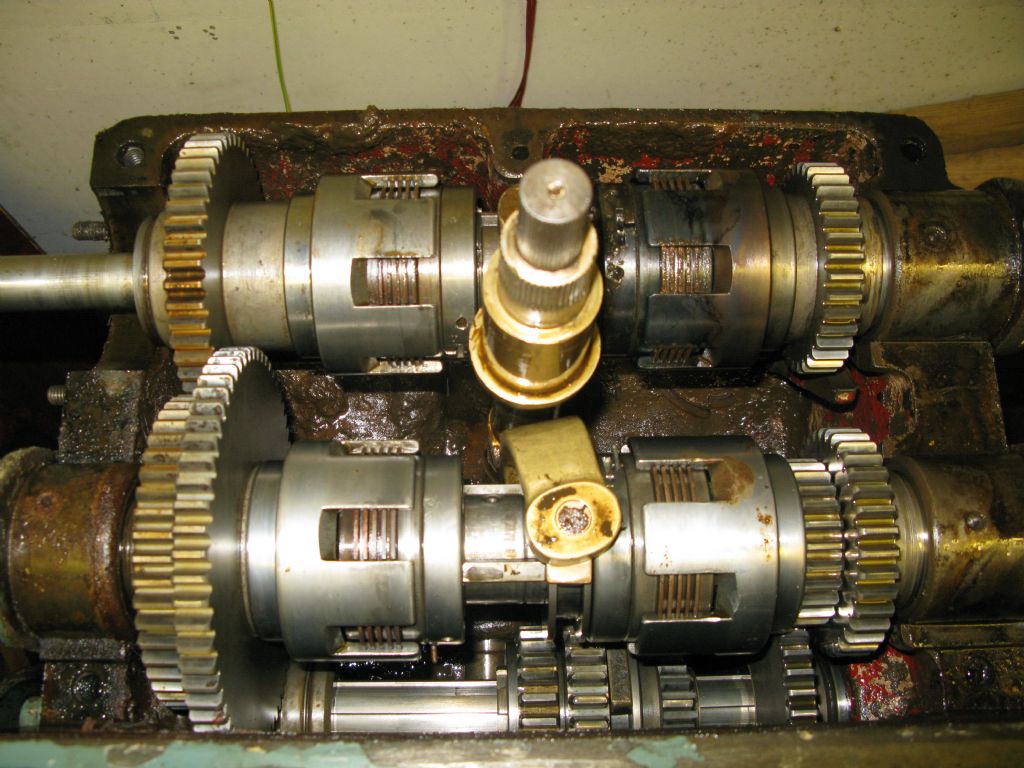

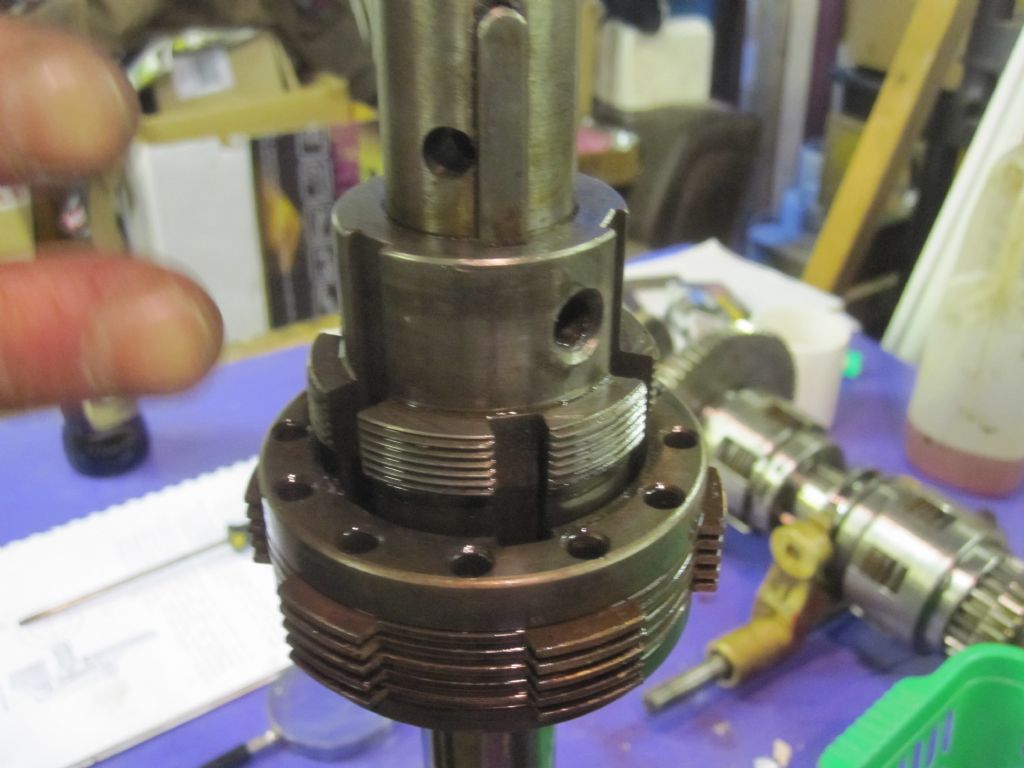

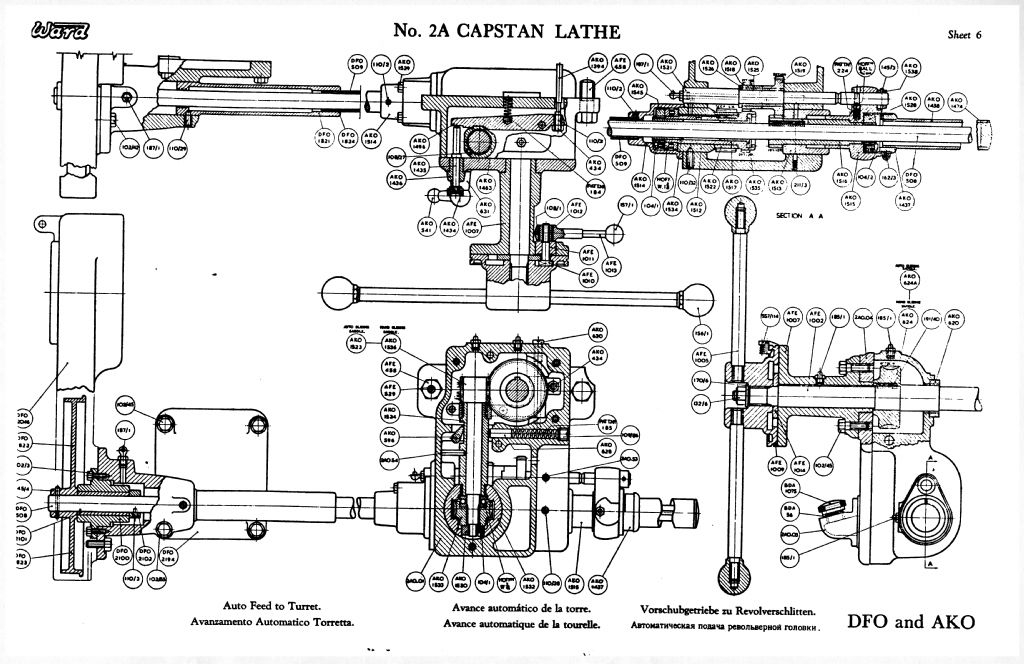

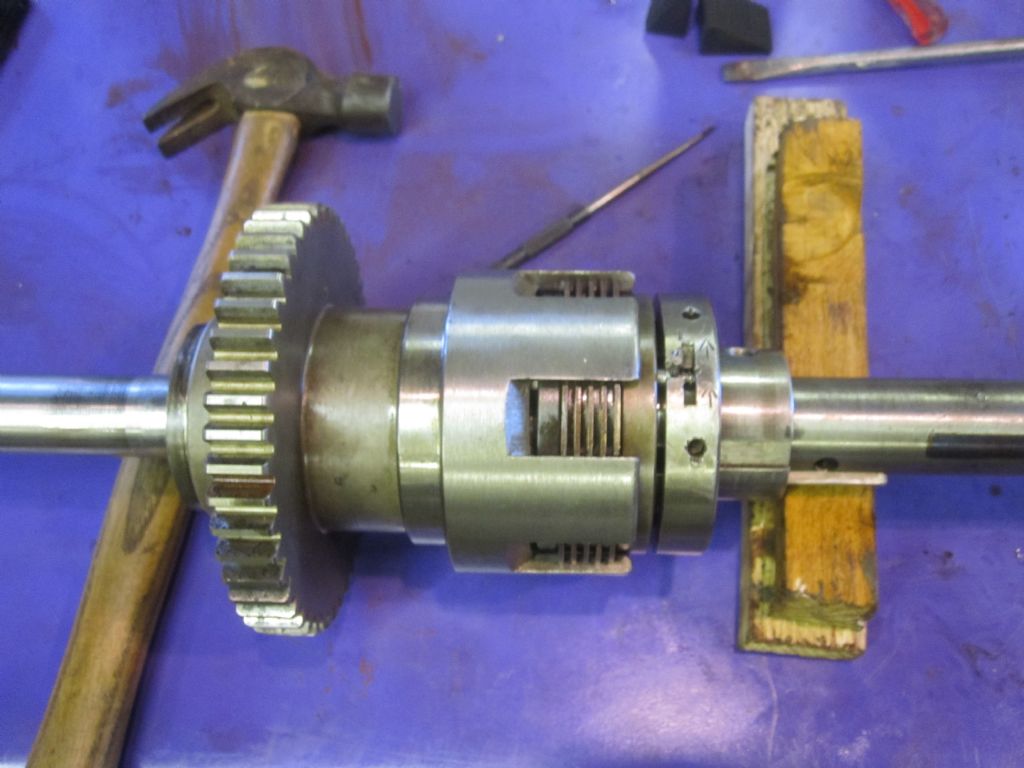

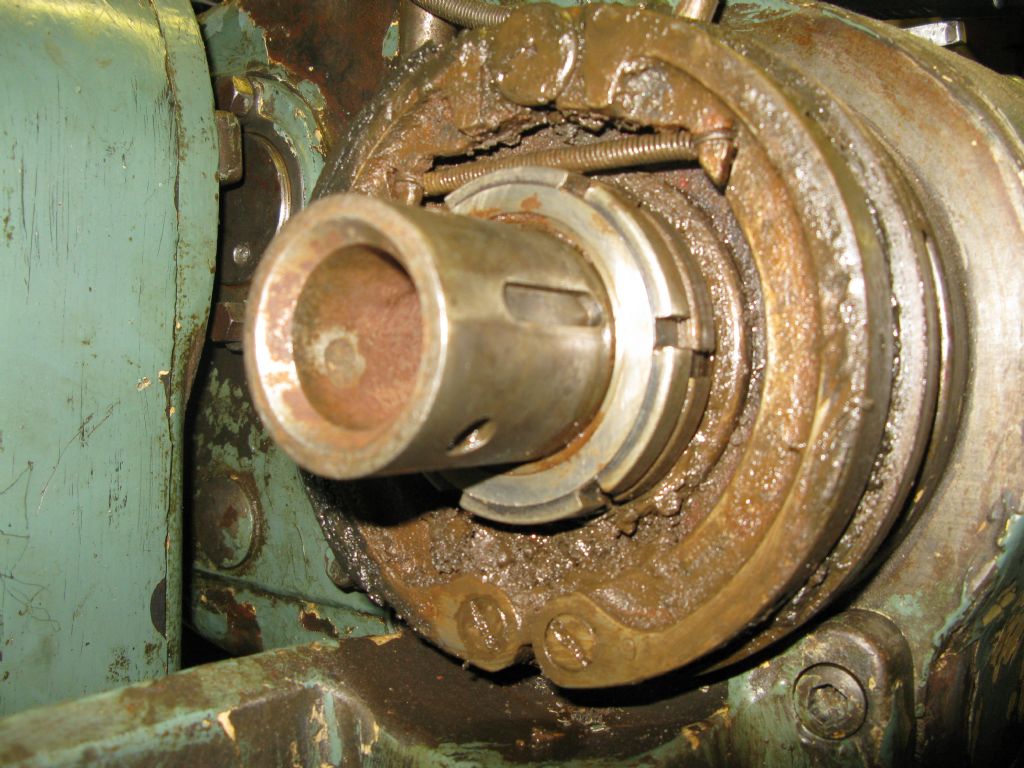

Cutting a lead weight for my Lehman seismometer. . The oil pump still only feeds a drip onto the clutches . I recut the piston on my myford and overcut it, doh! , not as bad as the first time, but by 0.1mm dia. and it still doesnt really pump fully. we will ream the cylinder and take more care next time. The pump CAM also has a rim on it so might be worn so not really pumping to full capability. The cam is on a tapered spline so options are to replace whole or build up from weld and regrind. Once the gearbox is at full speed the oil splashes pretty freely anyway.

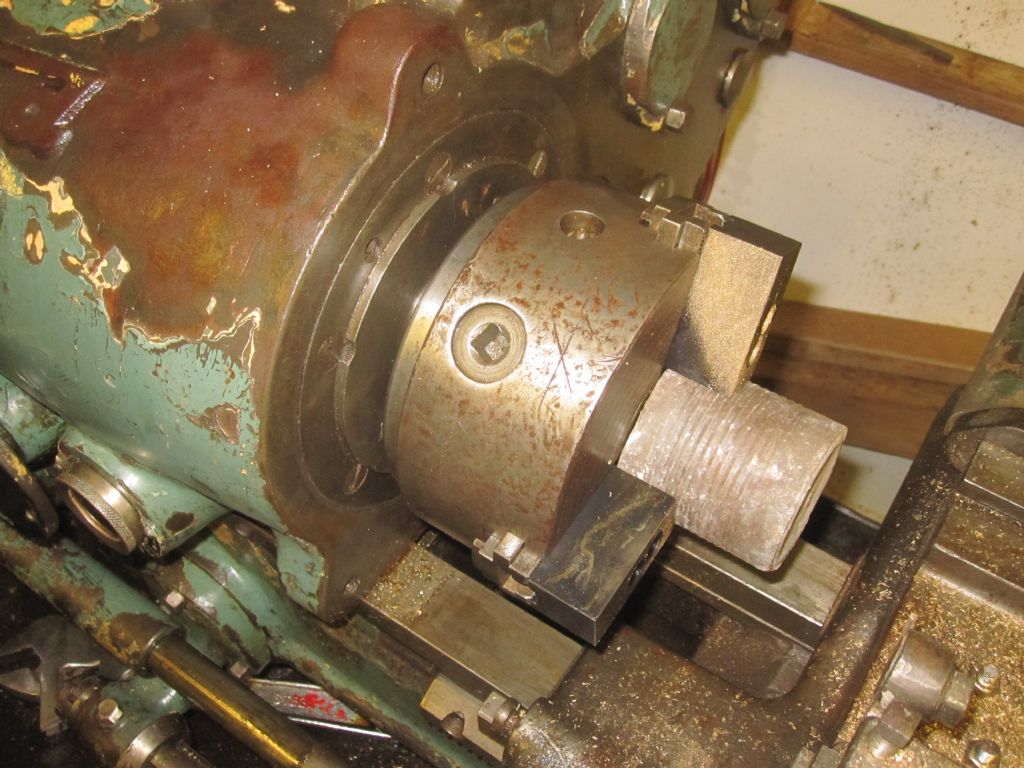

The tin cast lead weight in the Jacobs 3 Jaw chuck with new jaws, not shamfer cut for small bars.

Parting it off obviously too fast, it melted the lead and ripped it from the jaws.

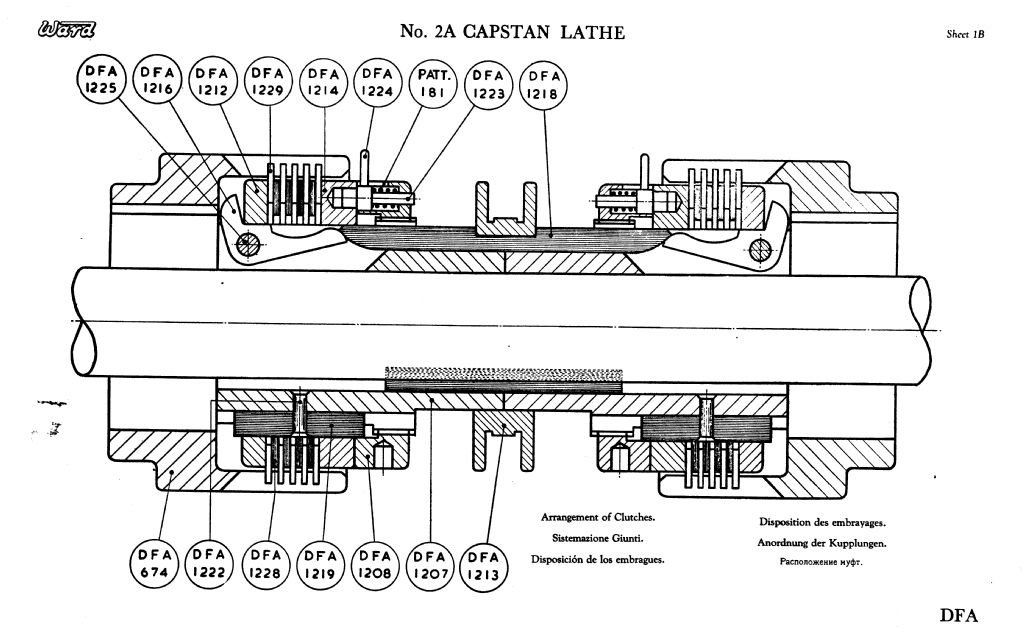

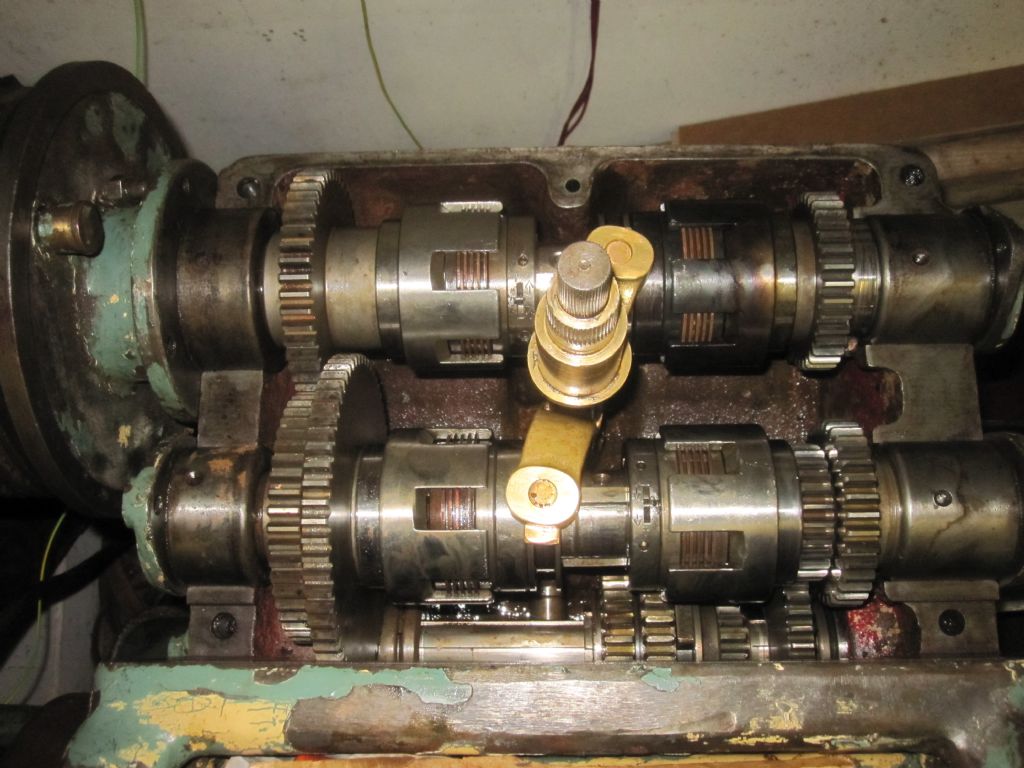

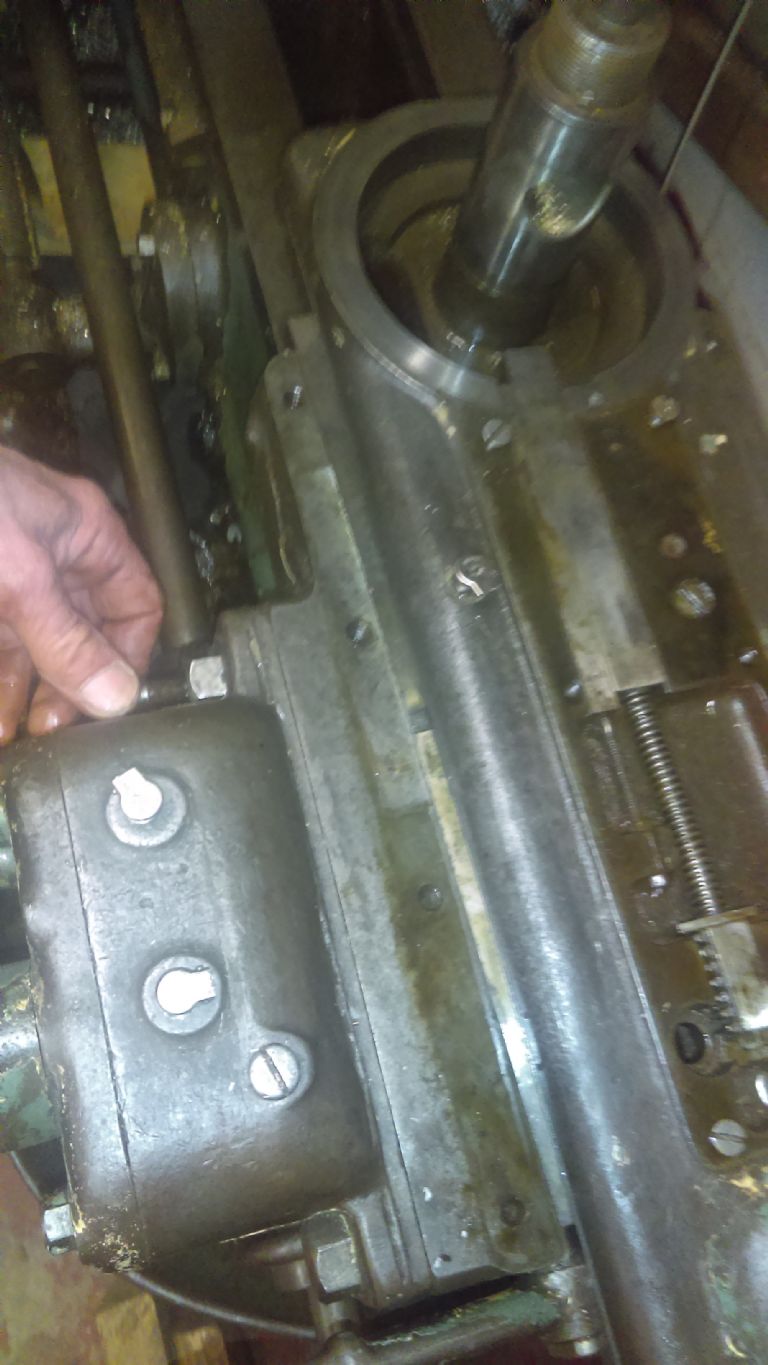

But tonight we ran the lathe through all combinations of clutches and gearbox settings. fast forward, fast reverse, slow forward, slow reverse. for all three gearbox settings. and it behaved beautifully.

The oil feed is still a concern .

BUT now we can move on from input to reward ! . what can it do for us !!!

well we need tooling. , the Turret has 1" holes with a larger diameter recess I assume is the tolerance part. we have two kinds of turret fixings. only one has a boss that engages with the recess in the turret .

Does anyone know the name of this fixture, with the boss. we would like to put morse taper 2 and 3 drills in, live centres, etc. .

Bill asked me if we has spent £1000 8 months ago could we have bought a machine that has the same capability as this one. well yes a colchester , ect.ect. but we would not be where we are today ,And with DRO and CNC and a new cross slide this machine can do anything we want .It might cost £1000 to add those things but we will have a one hell of a machine. And our machine might have made spitfires.

James Tarff.