If the wear on the axle box was due to connecting rods or crank pins, it seems like the wear would be forward and aft as the axle box was pulled and pushed.

But, since it looks like the wear is in the up and down direction, one would think it was due to some fault in the suspension.

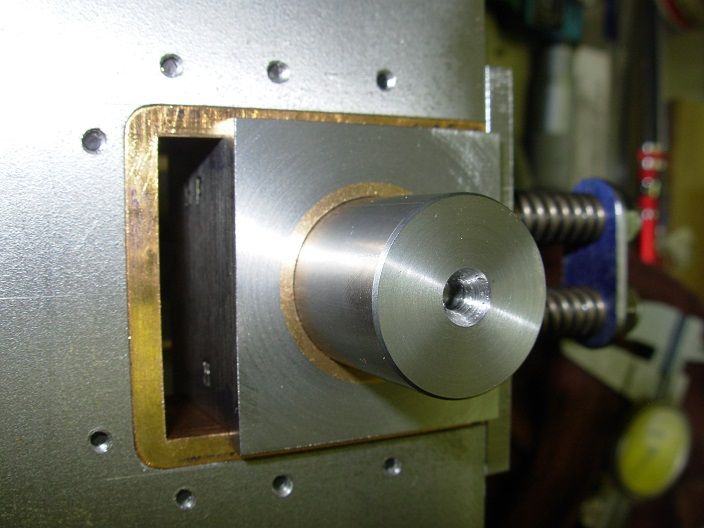

Stewart, I have oilite bushings in my axle boxes. It's not yet clear if I should have used bronze. In any case, I machined my axle boxes using an angle fixture bolted to a face plate in the lathe. Each axle block was clamped into the angle fixture and machined in the exact orientation that that each would be in the locomotive.

Using this type of a fixture, you could bolt up the axle block, of the pair, that has very little wear and dial it in to adjust the angle fixture. Then put the poorly worn one in, and re-bore it for bushings. Otherwise, the worn axle box leaves you very little for a reference to rebore it.

I did this for all of my axle boxes from the start and they turned out perfectly. Attached should be a photo of one of the boxes being bored and a photo with a test axle going through the bushed axle box and through the axle box on the other side.

David

Edited By David Wasson on 03/03/2018 00:34:12

Stewart Hart.