First thoughts

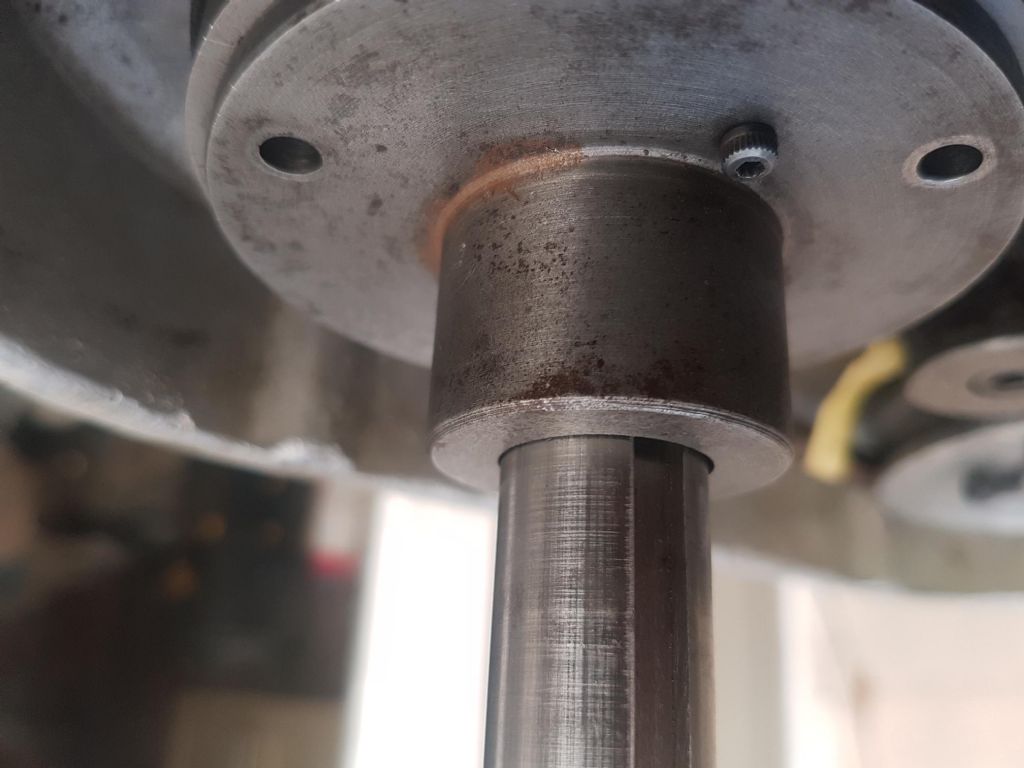

1 ) Your problem stems from the shaft / bush not being a close enough fit.

You need to investigate the fit between shaft and its bearings, at upper and lower ends, not the driving keys!

Possible solution.

Bore out the plate and fit a custom make close fitting bush. (May need doing at both top and bottom? ) Phosphor Bronze or Brass would be suitable materials for the new bush. Retain with and anaerobic such as Loctite, or with a flange and small screws.

Any chance of making the new bush (es ) longer, until travel is not quite reduced? This should improve location, and reduce wear in the longer term.

Is there wear because of a lack of lubrication? As part of the new close fitting (possibly longer ) lower bush could you incorporate a lip type oil seal, to prevent / minimise leakage? The shaft needs to be a good finish. A scored shaft will wreck a bush as you start up. Lightly lubricate the shaft where the seal will run, before installation. The seal should be protected from any sharp edge on the shaft during the assembly process by wrapping masking tape or plastic insulating tape over the edge at the end, before entering it through the lip seal. Once the seal and bush are in place, the tape can be removed.

Worst Case Scenario.

The Shaft is worn as well as the bearings. If so, you may need to think about skimming the shaft to clean it up, finishing with a polish with fine emery, followed by making new custom bushes, as above. M

Make sure that you remove all traces of the abrasive dust.

2 ) The keys only provide the drive to the shaft, NOT location, so do not need to be a particularly close fit.

Although, if you are really that keen, you could make two new stepped keys with the end that locates in the shaft a close fit, with the outer ends just a bit narrower, to be a close fit in the driving plate. Personally, I am not sure that any benefit would be worth the effort

If you are in any way not sure about this, find someone near you who has the experience to do the job with you. Joining a local Model Engineering Club would be a good start.

Where are you located?

Howard

Edited By Howard Lewis on 30/06/2019 08:52:37

SillyOldDuffer.