James,

Sorry for the delay in responding.

I have now had a chance to dig my workshop notes out on this rebuild – unfortunately I no longer have any photographs (the curse of mobile phones that get broken, lost, or stolen!) but from my notes I measured the distance between the bearing shoulders of the spindle quill and also the depth of the retaining circlips, the upper (AC bearing) clip gave a +0.004" clearance on bearing outer race width. I did consider packing this but eventually settled for 'as it was' condition.

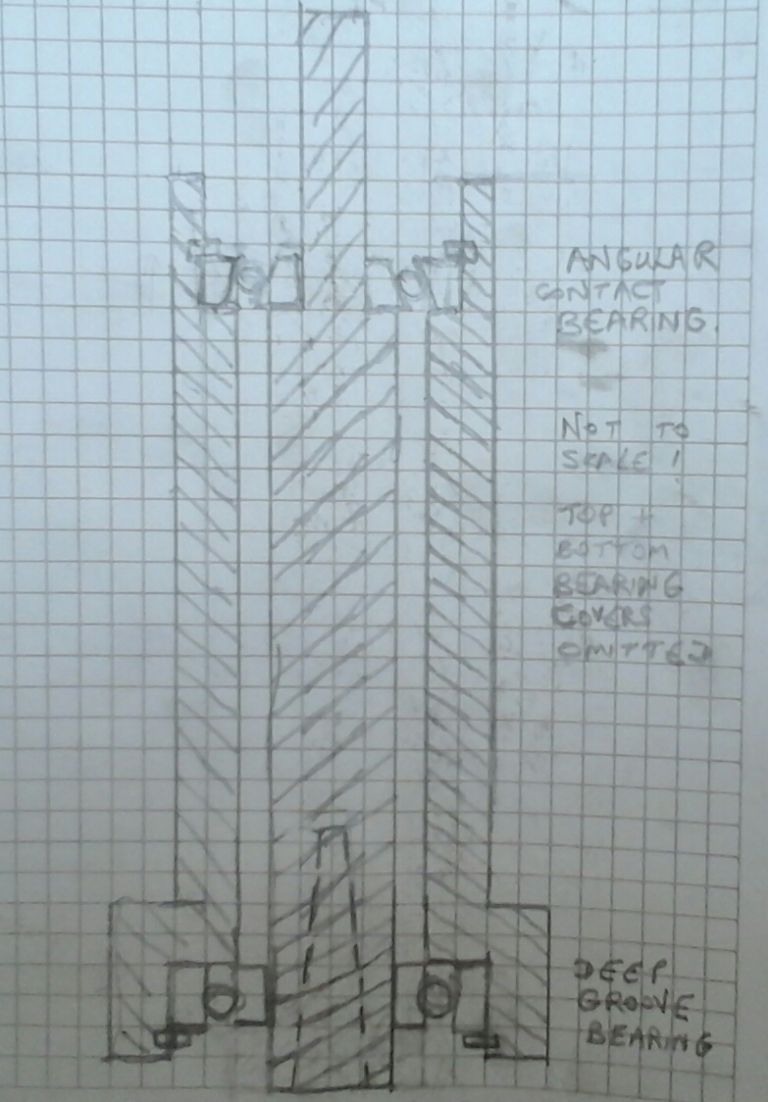

The way I see it the AC bearing supports the mandrel and the lower DGB 'floats' to accommodate the upper bearing. I used a Hoffman RLS8-V3 DGB and a SKF 7302 BEP AC. With it all assembled the end float was zero – I believe the end float you have experienced may have been caused by the AC bearing wearing through lack of lube, this will introduce end float. I would certainly recommend you check the gap between the top retaining circlip and bearing to ensure a close fit. A spring 'wobble' washer could be used if it is excessive. Also worth replacing the circlip if it is damaged in any way.

Let us know how you get on.

Have you any response about a manual?

Martin

PS – my method of assembly was to press in the AC top bearing into the quill, then supporting the inner race of the AC press in the mandrel which had the DGB bearing pre-fitted to the quill shoulder dimension, when the DGB outer race was ready to go into its housing I tapped it in gently as the mandrel was still under load. The upper bearing was as I said in the earlier post an 'easy' fit due to the corrosion from being in the elements. The drill has been fine with a very quiet spindle and no overheating.

Edit for PS

Edited By Oily Rag on 19/08/2021 18:31:05

Pete..

Pete..