Thanks for the video & link Peak4, makes sense now. One of the parts they thought belonged to the lathe was the saw table but I said it was from a saw of some sort, not lathe related, so I left it there. I'll pick it up before they toss it, although, as Hopper said, it's a relic of times when angle grinders didn't exist or required two people to operate

Item 8 doesn't seem to be used in the saw. Any idea what it could be for?

Alas, I did not get a 4 jaw chuck, the hunt begins… Maybe blasphemy, but anyone had any luck with the China chucks? I would also like to find a good faceplate.

I recognized part 2 as a knurling tool but was wondering if it was a good idea to attempt any knurling in a lathe that is this small. Perhaps I'm overestimating the force required. It's a nice tool to have though.

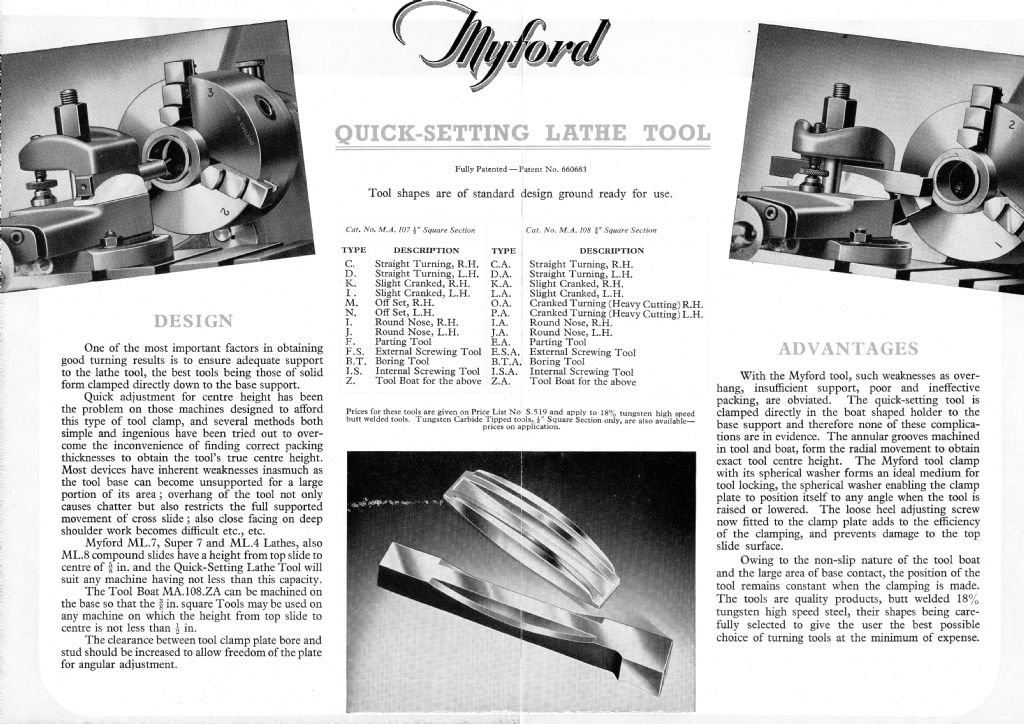

The cutting tools have the letters stamped on them, but the Myford site has a different code for them today it seems. I'll match them up later.

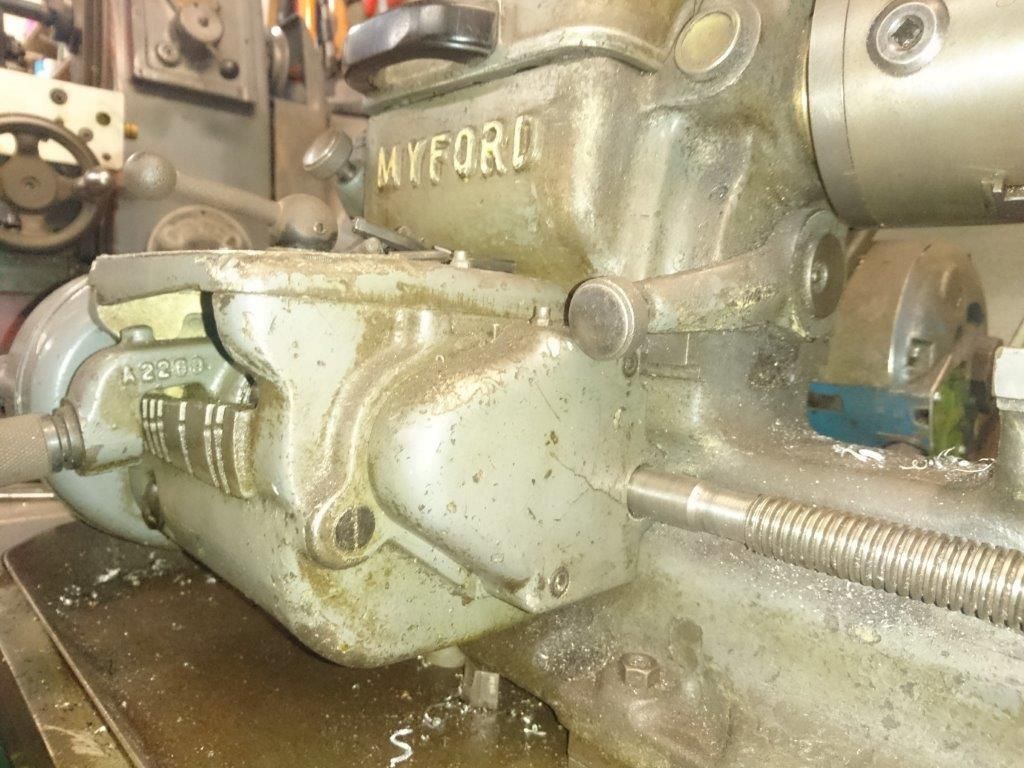

I didn't plan on going overboard in restoring, just clean, inspect, adjust & lubricate. I want to preserve the original gray paint but touch up where required.

I see a lot of the lathes with blue motors on them, possibly standard on the later models, but I wonder if this lathe has the original motor? Here is a pic although it didn't catch the markings well.

Thanks for the book suggestions Hopper and the warning, I can relate  What about the manual on the Myford site for non-power crossfeed version? Is it more of a parts list than an operation manual?

What about the manual on the Myford site for non-power crossfeed version? Is it more of a parts list than an operation manual?

Thanks all, regards

Hakon

Mike Crossfield.

A quick search revealed what a gem this was and I'm really excited to be part of a community of owners of such vintage machinery.

A quick search revealed what a gem this was and I'm really excited to be part of a community of owners of such vintage machinery.