Posted by John Munroe on 16/03/2016 14:47:22:

Posted by Ian Phillips on 16/03/2016 13:20:28:

Without knowing the purpose/loading of your application its hard to be specific. The simplest method would be two circlips in grooves close to the end of your rod.

Ian P

Hi Ian,

Actually, my original plan was to use two e clips. Do circlips and e clips serve different applications? The bracket is rotated and the torque is around 0.3N-cm.

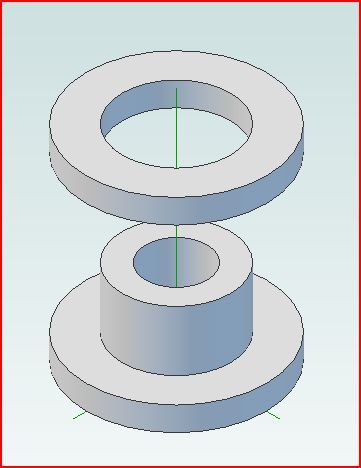

My current idea is something like this

(bracket end) E clip, washer, teflon washer | teflon bushing | teflon washer, washer, E clip (rod end)

where | xxxx | denotes the bore in the bracket.

I wonder if a washer is needed between E clip and teflon washer? The clip is held fixed by the groove, so it wouldn't exert much pressure on the teflon washer, right?

Edited By John Munroe on 16/03/2016 14:47:52

I used the term circlip in a generic sense.

Since you know the operating speed, loading and presumably other details, what you end up using is going to depend on what materials are involved, what engineering facilities you have and also how much you want to spend!

Mainly though its the end use or purpose that will determine what is the best approach.

How much play/looseness can you tolerate in the joint, does it matter if it a rattling fit, there might even be a rattle (noise) that detracts from the final product's acceptability, Slightly preloading the already mentioned PTFE washers would prevent noise.

Ian P

Ed Duffner.