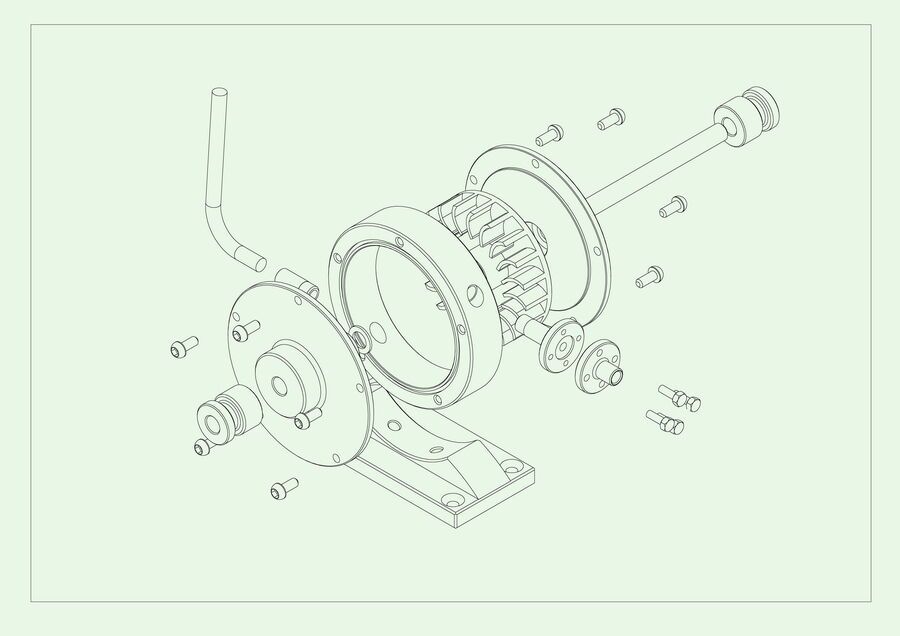

I want to see how the model turbines I have built compare with ones that can be purchased. The Radial Turbine Link describes the Radial Turbine I just purchased shown in the photo below. The radial turbines seem to be the type most available and I have not tested this kind of turbine. I picked this particular model since it appeared to be a good design that seems to have ball bearings on each side of the rotor as shown in the drawing below. It also includes a speed reducer which is something I have also wanted to test. I created a Radial Turbine 1 folder and will update it as I get more information. This model is coming from China so It will be about a month before I receive it.

Edited By Turbine Guy on 09/01/2023 20:55:37

Edited By Turbine Guy on 09/01/2023 20:58:27

The quoted post describes my purchase of the turbine I call Radial Turbine 1. The posts following this post discuss my testing of this turbine and what others have done with this turbine. I believed that I could improve the performance by designing a radial turbine for the GWS EP 2508 propeller I use in my turbine performance spreadsheet. I thought that by reducing the blade height, covering the blade on both sides, increasing the amount the flow is turned, and adding a radius to turn the exhaust flow would improve the performance. I 3D printed the rotor I call Radial Rotor 2A shown in the following photo and used it in what I named Radial Turbine 2 shown in the following drawing. The following spreadsheet was updated to include the performance of this turbine. This design did significantly improve the performance over Radial Turbine 1.

Turbine Guy.