Honing with a brass rod and lapping compound, I acknowledge, was a cheap and perhaps less desirable method of three-jaw ‘rectification’ and, upon reflection, hardly necessary anyway.

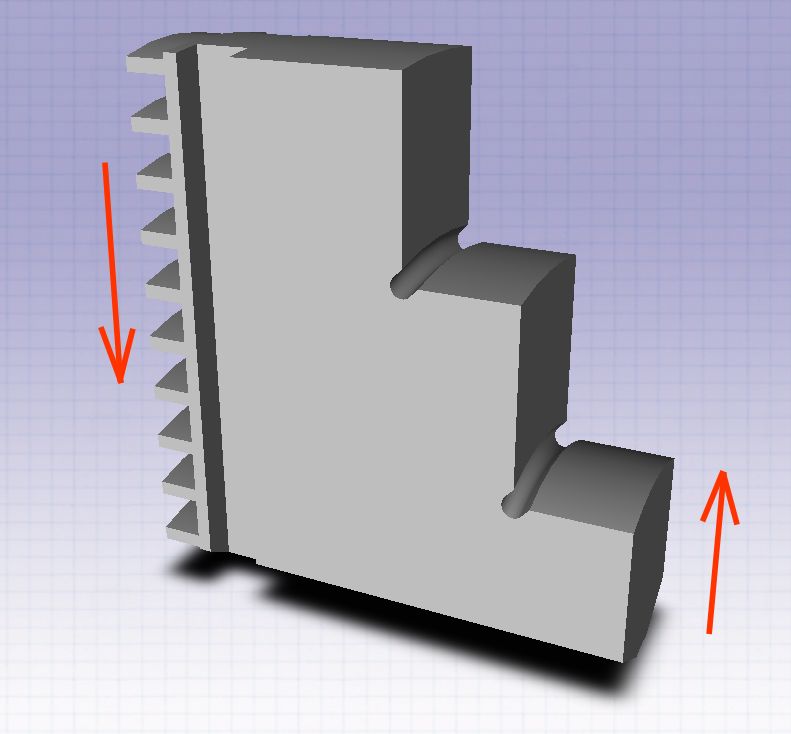

Not wishing to labour the point, I would however suggest that given any degree of play between the jaws and the chuck body, and a respectable NGP in the vertical direction, the jaws would tend to rotate/deflect (anti-clockwise in this diagram),

such that there would be more metal removed from the back of the jaws than the front, i.e. the opposite of bell mouthing. I would not care to determine what the results would be from lateral (jaw) twist.

"Twist'ut jaw and lack'ut theen" was a phrase I recall, although my vernacular spelling might be a bit suspect.

Given the need to carry out such 'improvements', I would certainly favour Old Mart’s hole-drilling technique.

Incidentally, the use of collets for repeatability and accuracy was my preference too, OM.

These went with it when I sold the ML7.

Sam

NGP = Narrow guide principle

PS – Was there more than one version of the Griptru chuck? I can only relate to the version with tangential conical wedges. It was possible to centralise the chuck to within 0.0001", so long as you stayed with the same stock diameter, and in that case always selected the same keyhole for the chuck key.

Edited By Sam Stones on 22/07/2020 01:18:00

Hopper.