Martyn,

I agree with Hopper, and you can easily check the truth by measuring the diameter of both gears, they should be identical without having to go to the trouble of counting the gear teeth.

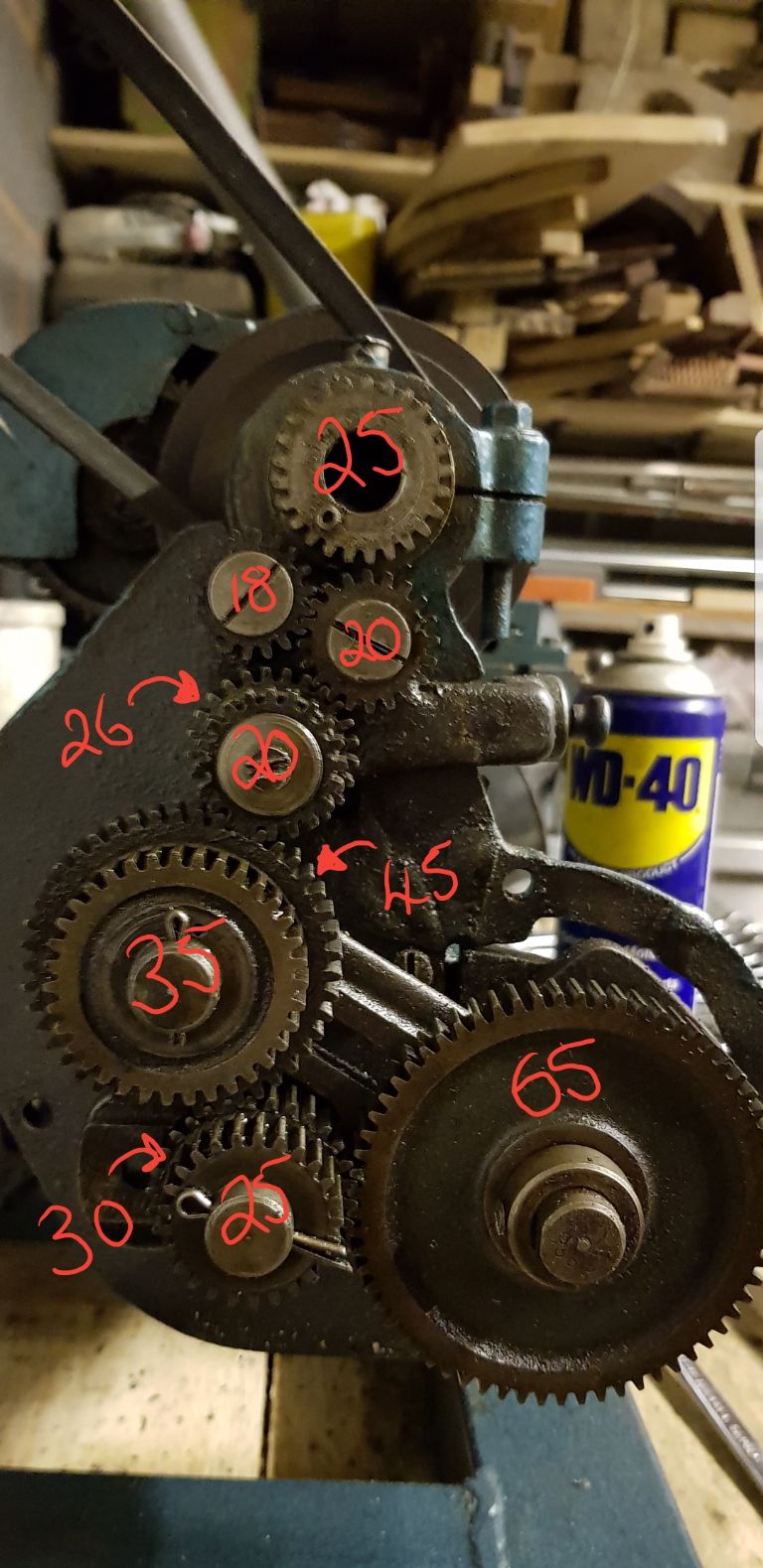

ML 4 lathes were all fitted with a 25 tooth gear on the spindle, locked as yours is with a grub screw across the joint and it was matched after the tumbler reverse gears by an identical 25 tooth gear. The stud that is mounted on was extended to fit the first gear in the chain, the so called Mandrel gear.

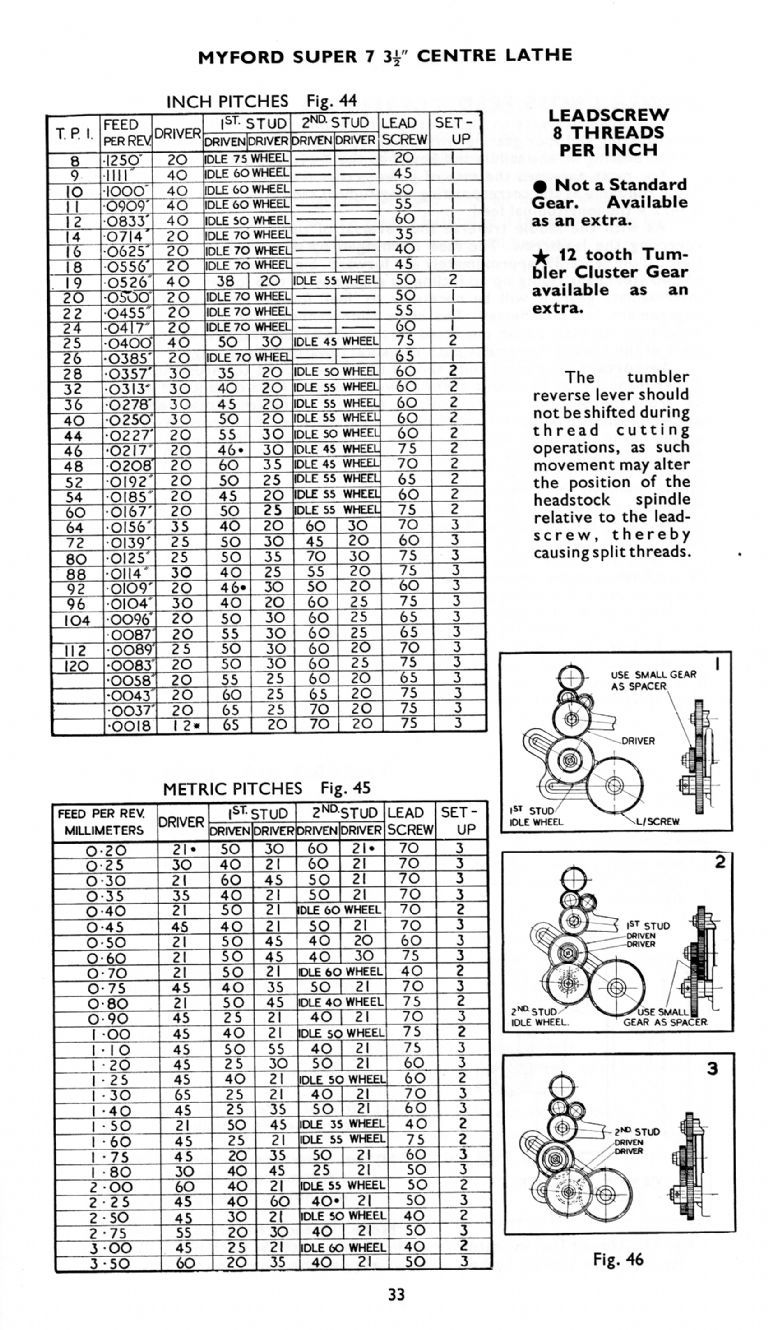

The reversing gears are both idlers and play no part at all in the calculations

And your earlier thinking on the differing charts is correct, there are often several ways of setting up gear trains that give the same result for the pitch of a screw thread, no one result is better than another.

Regards

Brian

Martyn Grogan.