Hallo Michael,

I also tend to think of myself as a model "maker" for some of my engineering work – but the only other clue that I have to the size of work you are considering – is the reference to a 4" blade capacity (diameter?) – so something like a Proxxon FET maybe?

However, in my experience, there is no single perfect "universal" cutting tool that works for all my needs – in wood or metal.

So (for instance) for wood – I have several sized table saws and a bandsaw. The bandsaw is great for generally sizing stock materials and also if I need any curved cuts (although I also own jig and scroll saws of course). I can run the stock through it and get stock to general shape and size. It may still need edge jointing or sanding. My table saws will not handle all of the work that the bandsaw can do but they are generally much better at making straight and very accurate cuts once I have the materials near to finished thickness.

Working metal has some similarities to wood work but the range of tools I use is larger and perhaps more specific to material and it's size. My 3-in-1 machine can cut (shear) tinplate quite well but will not shear the 1mm mild steel quoted in the handbook. For very heavy & large cuts (to reduce thick stock to usable size) I have a large reciprocating McMaster power saw – slow but powerful. For roughing small'ish stock, I've a small (Aldi) bandsaw that I can use as a chop-saw or held vertically – but neither of these are finishing tools. I view them both as a way of preparing stock to a workable size (so very like my wood bandsaw in that respect.

Of course a 'model engineer' will be finishing most of their parts in the lathe or milling machine – so possibly won't actually "saw" that much (or at least won't think of it as such). And this is why I wondered what size (and type) of "modelling" you have in mind.

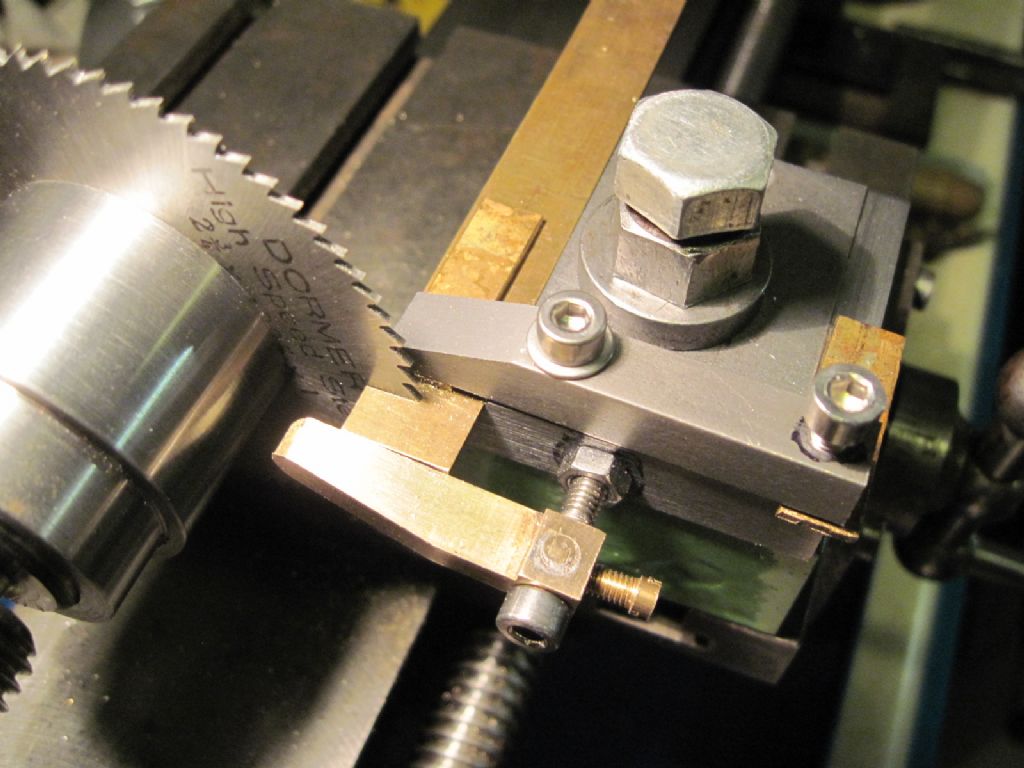

I don't have one – but a Potts saw table (a Hemmingway kit) mounted on a lathe will cut small brass and aluminium plate very accurately – either by hand or using the cross-slide feed. It will cut quite thick sections (if clamped) using an ordinary slitting saw. Because it's using the lathe's spindle – you can adjust the speed to suit the material and saw diameter used.

Of course, if you only need to cut very small or short items – then a simple saw arbor and a jig to hold the work may be all you need. I have several such arrangements, as well as horizontal mills that can handle my larger/longer 'sawing' needs (but I'm assuming you will not)

So, to summarise. The hobbyist 3-in-1 will not cut/shear much above 0.5mm (at least cleanly) in my experience, a metal bandsaw will cut most things but will almost always need further finishing work on another machine, whilst sawing on the lathe (or with the mill) can often be to the size and finish required but will need some extra set-up time to prepare the machinery for use.

Regards,

IanT

PS The Proxxon FET table saw will cut non-ferrous metals (with the right blade) but I do wonder how long it would stand up to doing so – I assume it's mostly intended for wood. A Potts lathe-type saw attachment involves some fiddle with set-up time but will be as robust & reliable as the lathe that's being used….

Edited By IanT on 23/03/2020 00:24:41

IanT.