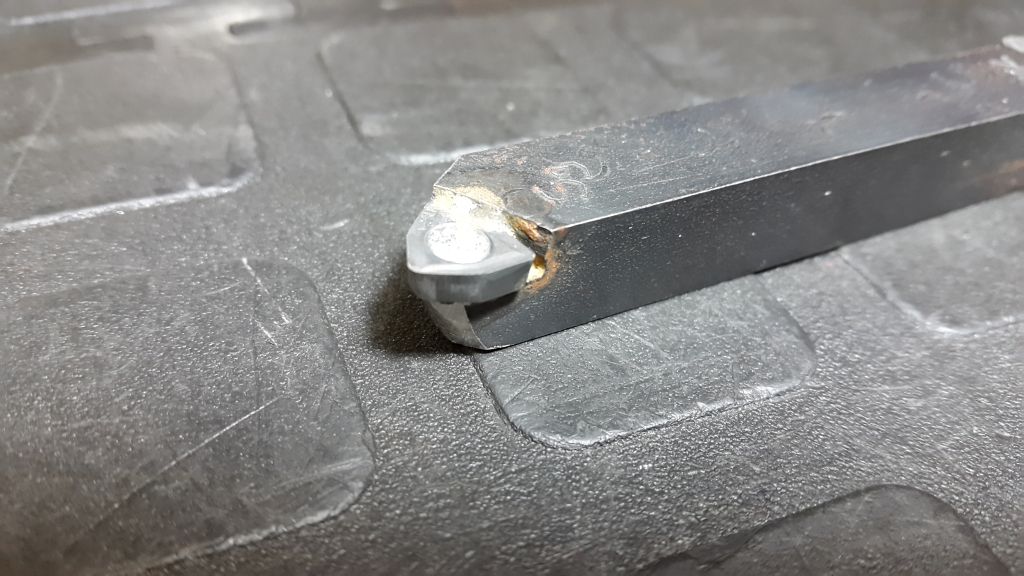

Hi Nigel, all makes sense, but if you’ve machined over 50 wheels it’s more of a chore than fun. The beautiful thing about this hobby is you can never be bored, currently my interest is in developing an alternative alloy for steam cylinders as tin is becoming exorbitantly expensive; cast the first cylinders a few weeks ago. The little ‘skinny’ mandrel handles a 1.5mm roughing cut without complaining which is not bad considering I mix my cast iron to be harder on the outer profile for my non-tired wheels; this is of course with chromite sand in this area. The wheels I cast in this fashion actually outperform the tired ones.

I started restoring bikes when I was at school, I don’t recall having any problems clocking the drums and skimming. I do however recall battling with rebuilding and truing up the wheels. If you interested in vintages I’ve uploaded pics of my 58 and 25. I had to make the brake shoes for the 25 as they were missing.

This morning I did a few experiments on a spare wheel, and I found a few ways to get rid of the chatter. Buffer’s method worked also, thanks for that. I think this little exercise will make a nice write-up, thanks to everyone that pitched in and steered me in the right direction.

PS: Buffer can I mention your method? If so can you PM me your name for reference.

Luker.