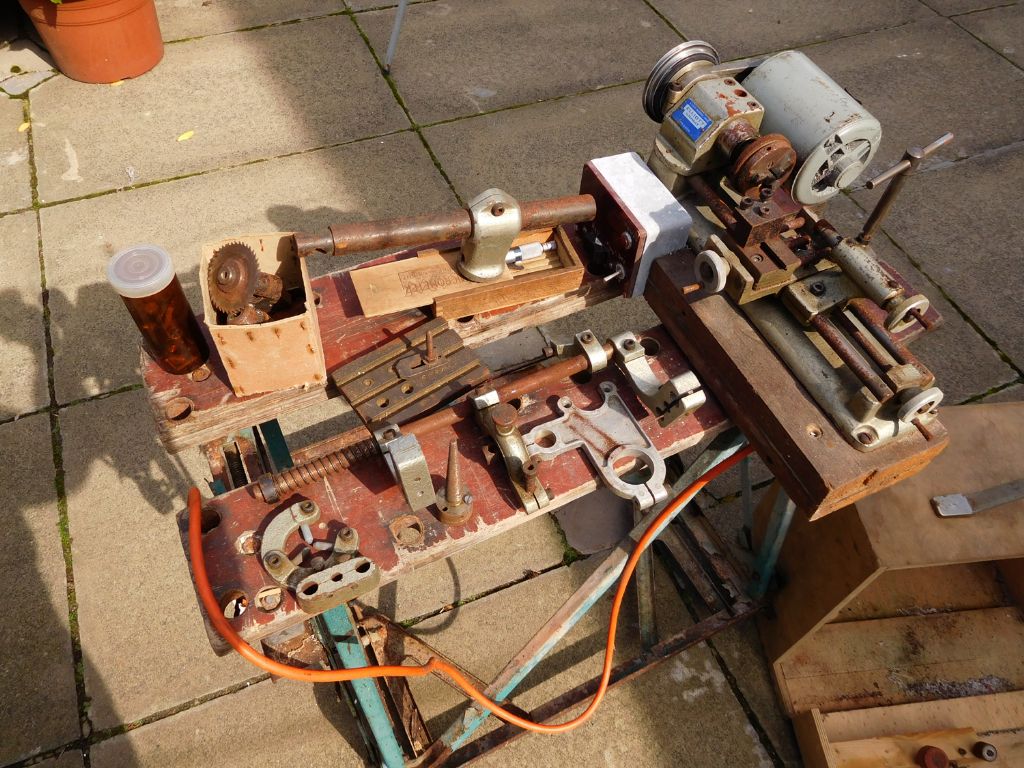

Glad to see you are making progress. Probably worth undoing the three screws and taking the backplate off the chuck too – will help with cleaning up. Probably best to mark it first so that you can keep the same orientation on reassembly but not sure if it matters.

The cross slide bars can be removed – IIRC they are held in by pointy ended grub screws but may resist even after removing the grub screws. Removing these may help 'divide and conquer' and will make cleanup easier. I put mine back in the other way up because what had been the underside looked better.

Looks like yours is a cast iron one like mine. Based on the info on lathes.co.uk I reckoned about 1961 for mine. Mine is badged 'Selecta Unimat' which may or may not be relevant to dating.

I also stripped down the spindle cartridge before putting mine into use. The ball races (aka magneto bearings) are easily replaceable and not expensive. I decided mine were OK but it was good to clean them and pack with fresh grease – I doubt it had ever been done before.

If you havent found it already, the Unimat group on groups.io is worth joining – there are both UK and US folks on there and some good stuff in the files section. They do like a Unimat SL on the other side of the pond.

https://groups.io/g/Unimat

Regards, Andy

Emgee.