If it works for you Alfie – then sure – parting-off is fine but there are other ways to do it (as suggested above).

To my mind, one consideration is the 'fiddle' factor. If you are only doing one or two lengths, then your way is simple and presumably uses the kit you already have. If you have a large number to cut then there is the hassle of stopping the machine (OK if you have a clutch), easing the chuck off, re-setting the work to length (and any required internal support).

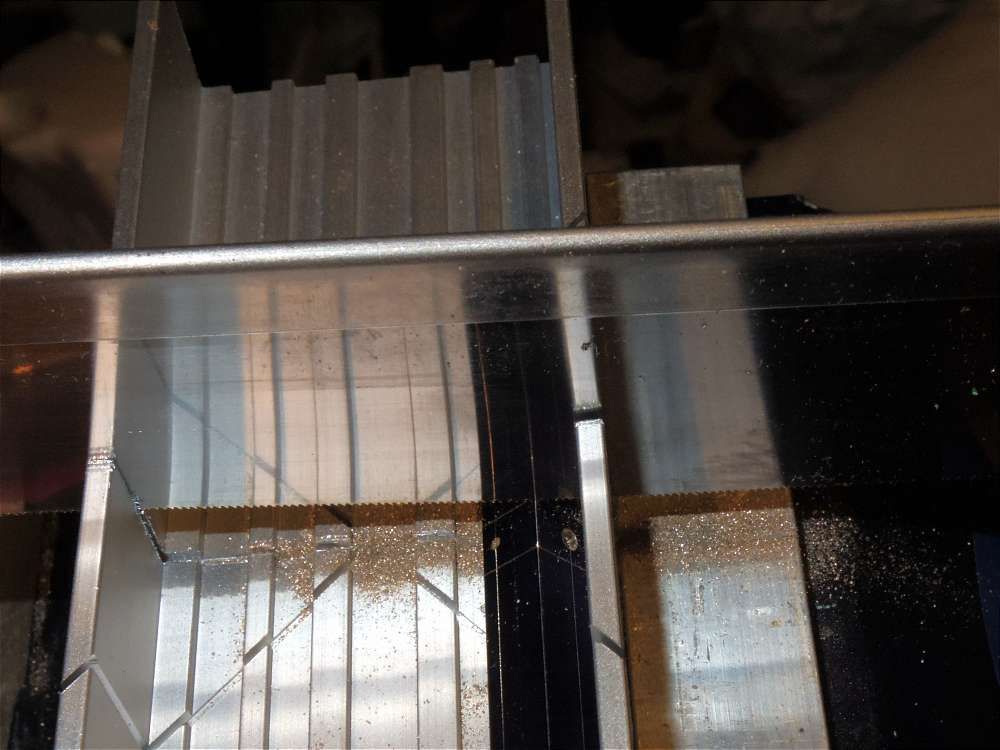

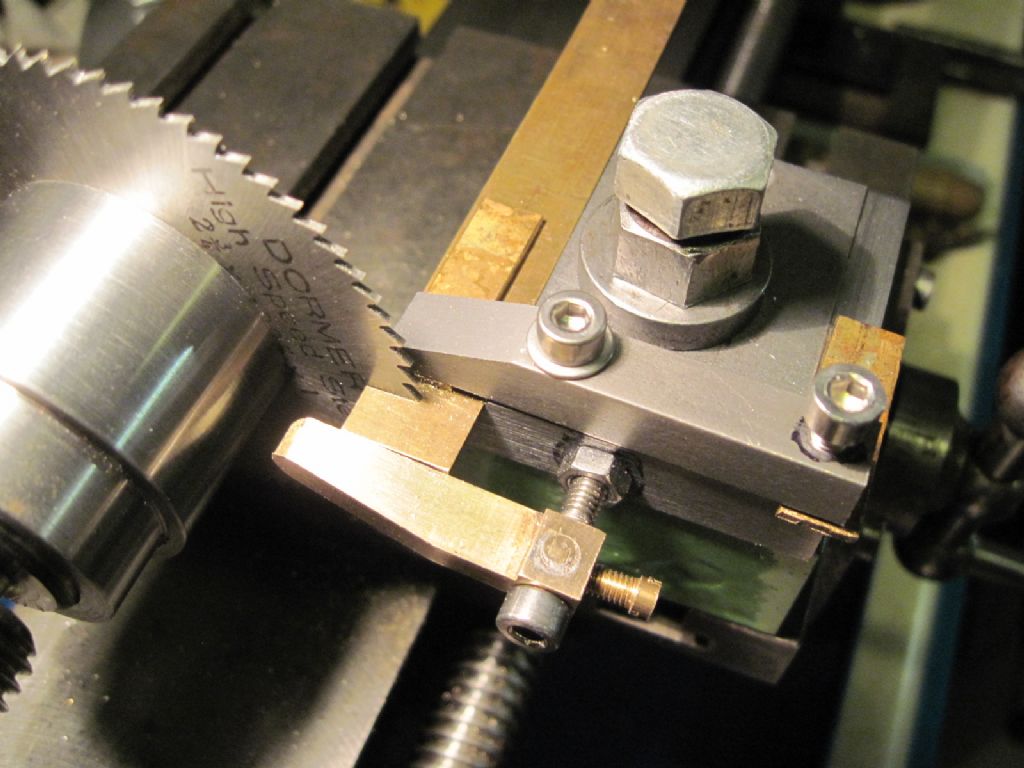

I have a very simple table-saw, which is just a steel square with a 'built-in' toolmakers clamp and a length-setting gauge. Once set up, I can run the cross-slide back, unclamp the work, slide the material forward, re-clamp and take another cut with the cross-slide. It's quick and accurate enough for my needs. I've used it for brass strip and rod too but not for tube (as yet). If I needed the tube internally support, I would find a way to clamp the inner support material further back and then I could slide the tube forward without needing to cut the support too (I hope that makes sense – the first cut would simply set the internal support bit to the correct length). I use the finest slitting saw I have. I have several 'tables' (with different depth slots & v-guides on each edge) – they bolt to the normal tool-post support instead of the QCTH base I (used to) use…

This may explain it better.. (P.S. I like it when other folk post photos – so I try to do so myself too)

Regards,

IanT

Neil Wyatt.

Neil Wyatt.