Apologies if what follows is overly negative, it's partly personal opinion! Even though I have the test gear and a long running interest in electronics, I don't enjoy diagnosing especially without a circuit diagram! Faced with this problem, I'd do a few simple checks, and if the answer wasn't fairly obvious, I'd flash the cash and replace the board.

Too late now, but dealing with faulty electronics, it's best not to rush into taking stuff apart. Diagnosing electronics isn't as simple as fixing a mechanical mechanism where how it works and what's wrong can often be sussed just by looking and poking at the parts. Unless a faulty electronic component is actually smoking, it's not obvious what's wrong. Now there are two problems: the original fault, plus new issues resulting from the board having been removed and bits de-soldered.

The initial symptoms suggest a faulty potentiometer. These contain a carbon track along which a wiper arm rotates. They're prone to wear and vulnerable to dirt. Made-down-to-price equipment usually contain ordinary consumer pots, which aren't made for constant use in a dirty workshop, rather than the much more expensive sealed units available: it's cheaper to replace 4 or 5 ordinary pots than to fit a fancy one once.

Intermittent pots can often be restored by squirting switch cleaner from an aerosol can inside through a gap in the casing; I use Servisol, other brands available. Otherwise, replace the potentiometer with one of the same ohm value, type linear.

Running at low speed after a new potentiometer was fitted suggests the pot is the wrong ohms value or was wired incorrectly, such that the control voltage wasn't getting from the pot to the board. A multimeter set to measure about 12V would confirm the pot is working correctly and the control voltage is reaching the board.

Only after that would I look deeper, and the device Steve has removed is a suspect. As I don't know the board in question, to be sure of what the 3-legged beastie is, I would have to look on the web for a data sheet matching its part number. Could a bipolar transistor, FET, SCR, or a Triac; it matters – how they measure on a multimeter varies.

With luck one of better motivated and qualified motor experts will be more positive than me. If not, my list of preferred alternatives, in order of easiness:

- Replace the existing board with a new one – Amadeal seem to stock them, about £100. Advantage is it fits straight into the existing lathe and the reversing, NVR, pot and safety interlock switches all just work.

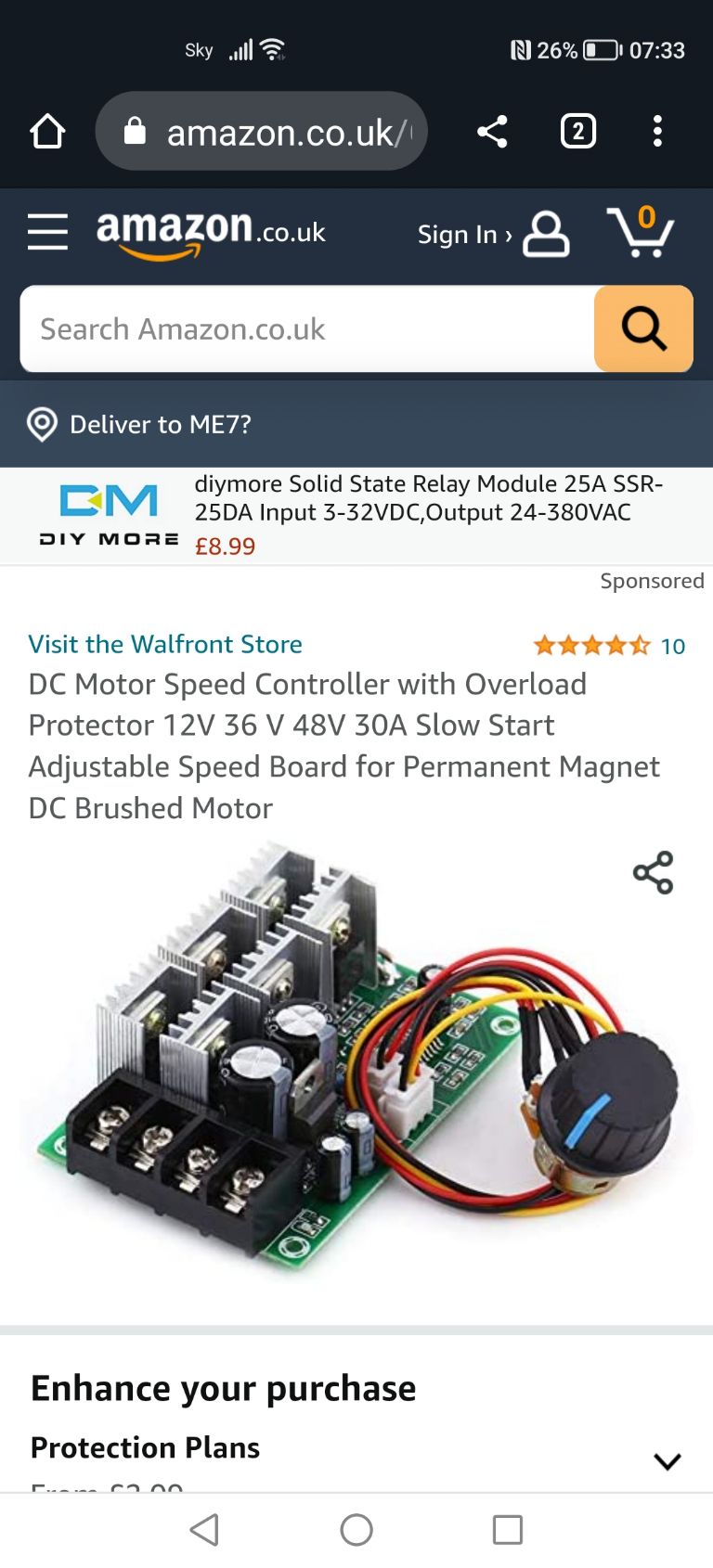

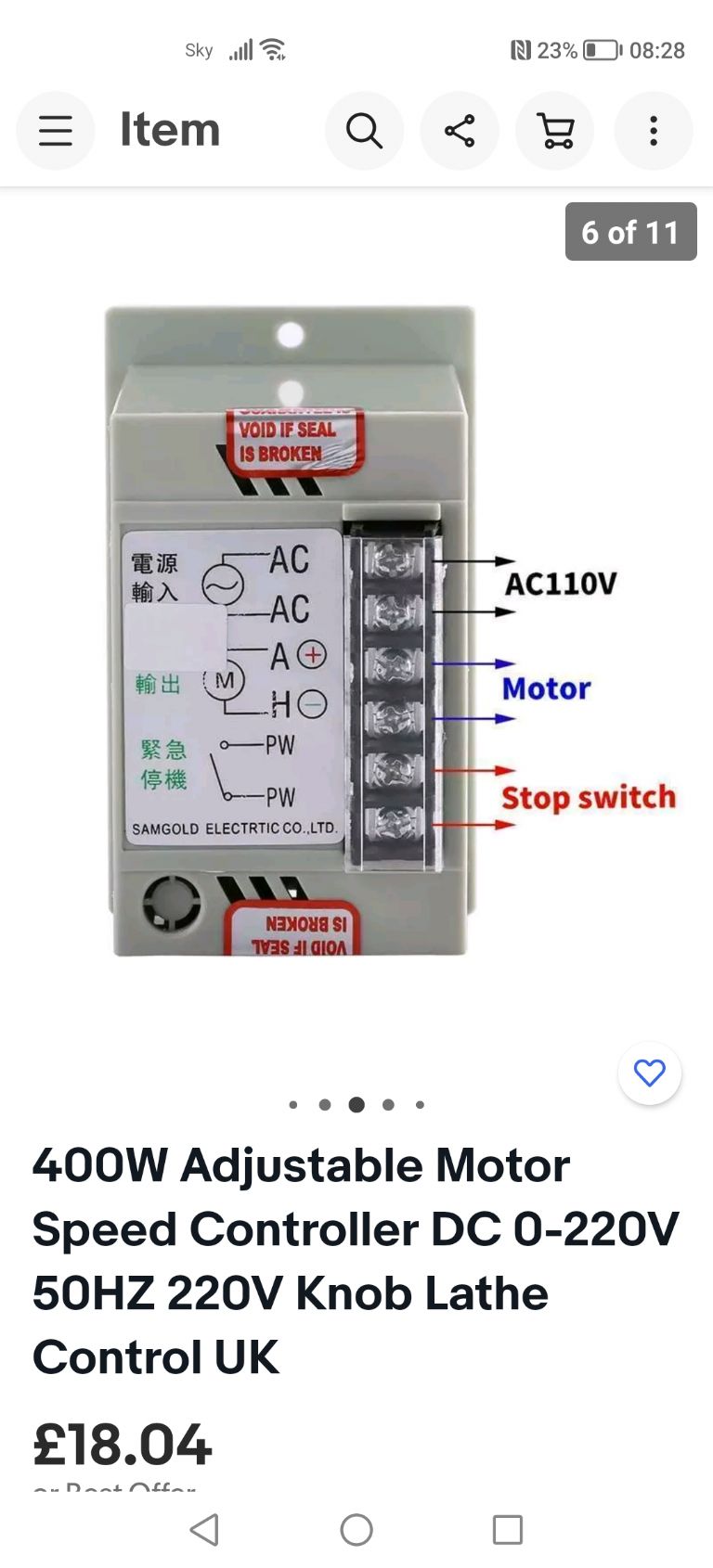

- Replace the board with an external unit of the second type pictured. The example illustrated would work, but even the 500W version is a shade underpowered compared with the motor. Won't deliver full power during normal cutting and might go pop if the motor overloads due to a stall. An unknown here – some power supplies are designed to protect themselves against all manner of abuse, others just emit smoke. No hint in the blurb as to how clever the unit pictured is, but a number of reviews say they've been successfully used on mini-lathes. Big advantage cost – £25. Disadvantage, more installation work compared with a new board, but not rocket science.

- Replace motor and board with an industrial Sewing Machine motor and controller. This option is proving ever more popular – power and reliability at reasonable cost. Disadvantage: everything is different, so more installation work.

The lathe is fixable, but probably not by basic multi-meter methods.

Dave

Steve Lang.