Hi Nyrup,

I believe that you ordered 060-325-22208 from this page.

After reading your post, I carried out some rough and ready tests on SC3 – Brushless Motor – belt drive mini-lathe. Usual disclaimers apply. Sorry in advance for failing to follow certain principals.

– Half Nut locked down on leadscrew – lever set to neutral, made sure the top slide was not loose – taking out any slack by adjusting the gib screws. Used the 000 QCTP and holder as it was already in place from another experiment. Adjust the blade to the centre or perhaps just below. 25mm diameter bars stocks used for steel, aluminium, and cast iron.

Parting off steel: Start off speeds needed to be played about with, and initial sounds we not so good.

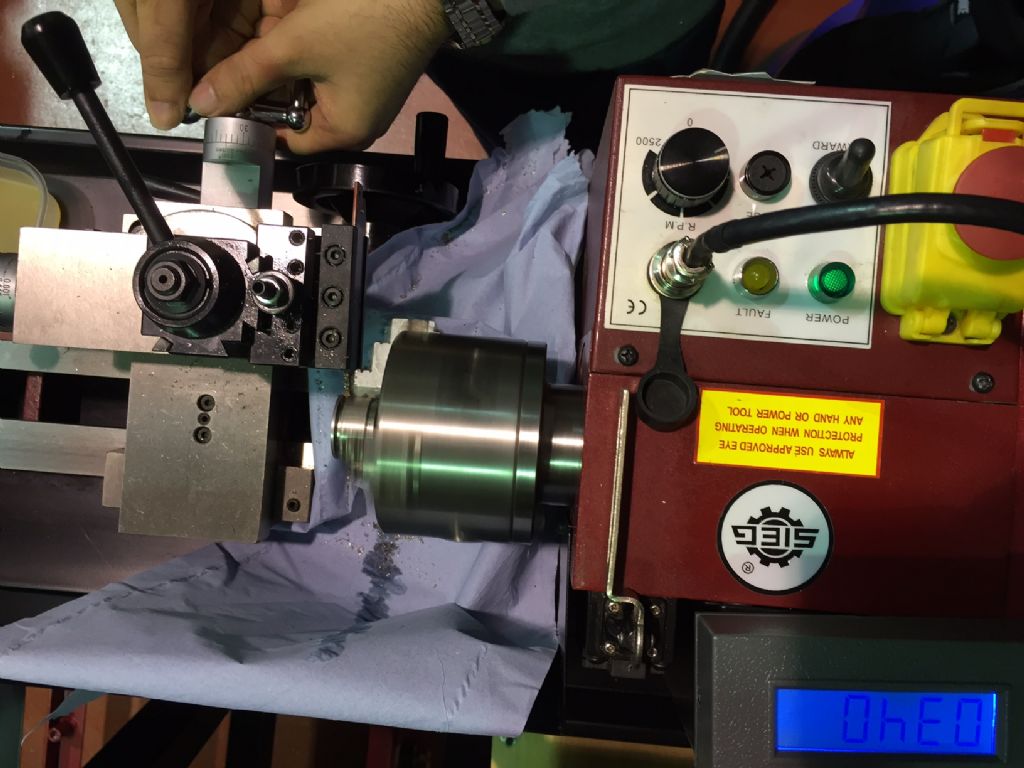

Speed reads 340 rpm. Picture taken upside down. Coolant applied at various stages with a small paint brush. Probably didn't need it. After getting about 5mm into the cut, the sounds settled and parting got easier.

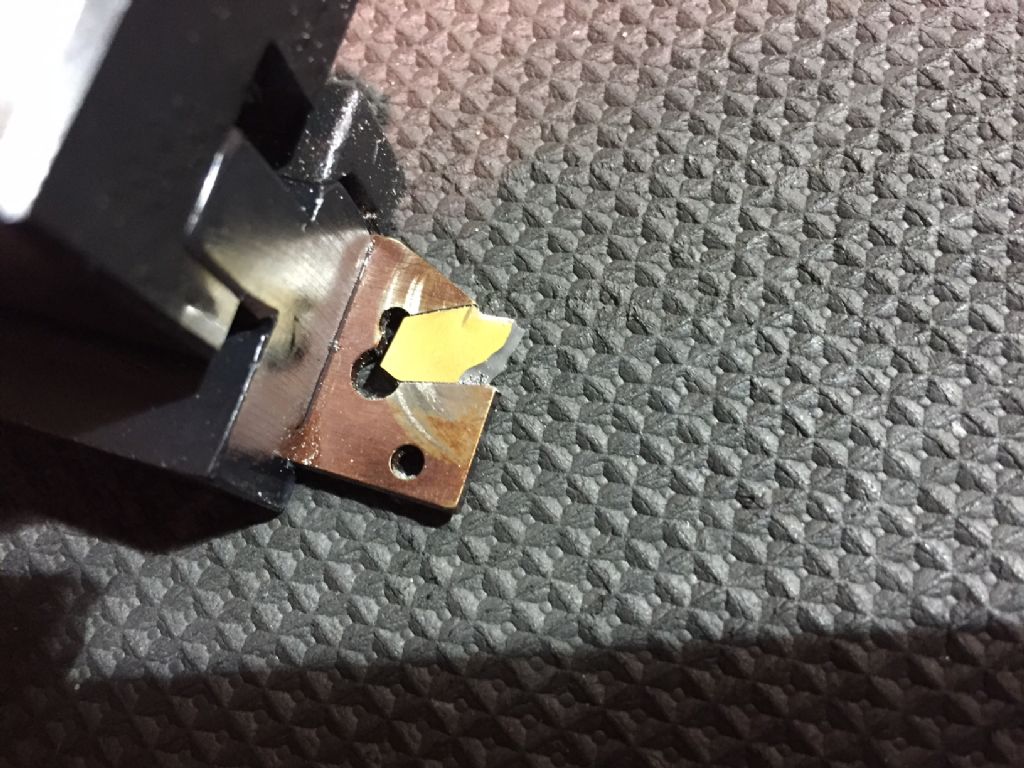

At this point I got a bit 'over-confident' and luckily the GTN2 insert just fell out of the blade. Couldn't figure out how to put it back in, so asked JS for advice. 'Hit back in' with nylon/rubber mallet:

Job done, back to parting off the remainder. Figured out that I had not quite got the tip to line up with the center. Still parted off:

Aluminium: After conducting above test, proceeded to part off Aluminium, initially at around 1,300 rpm:

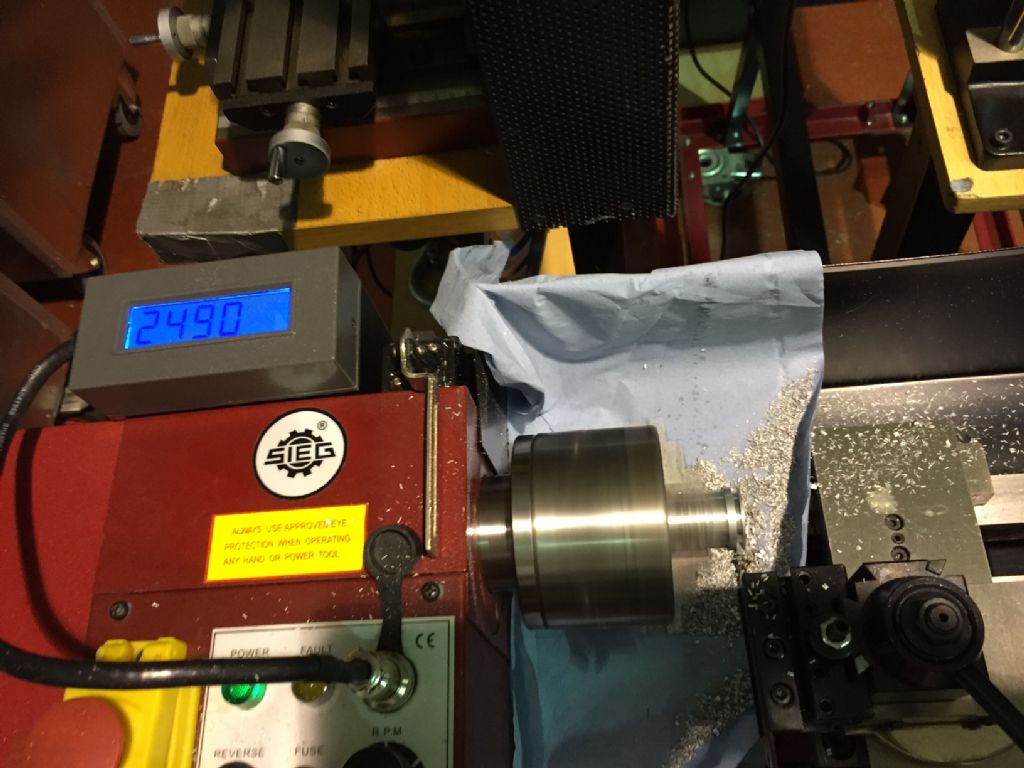

Liked the sounds at this speed, no need for coolant, so increased the speed to max. 2500 rpm just to see what would happen:

Confetti time. Not really recommended unless you also wear a face mask, but looks and feels really nice:

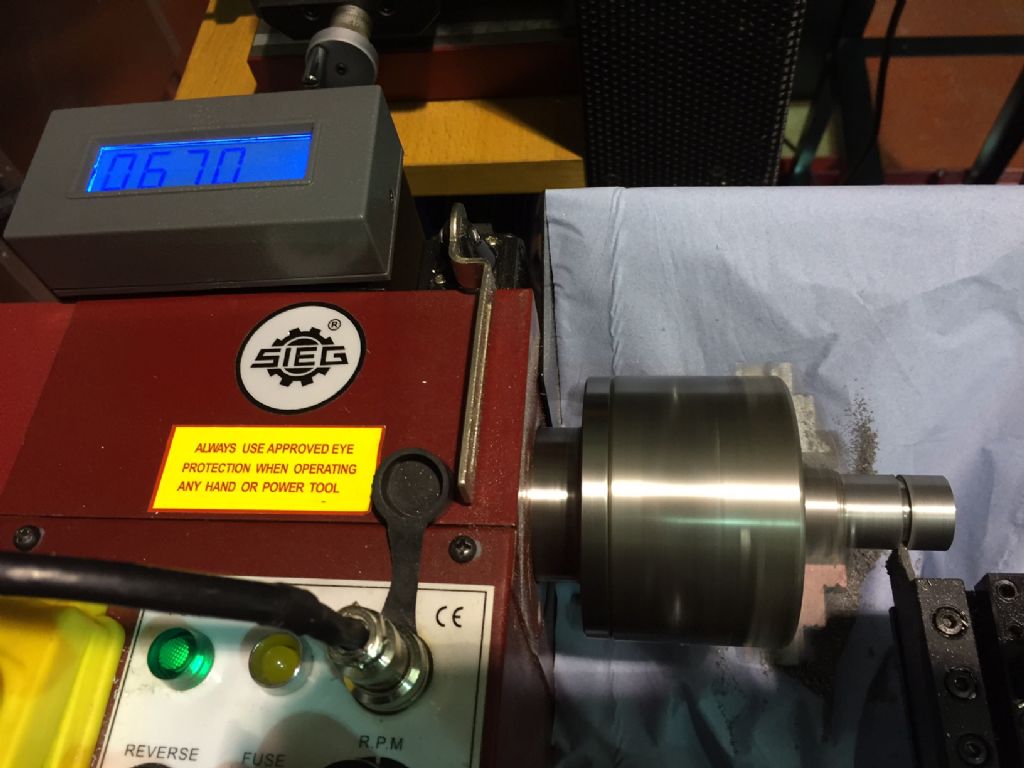

Cast Iron: I must have some really dirty stock of this, or, this stuff really behaves badly, or need to play more with this, perhaps adjusting tip height, speed. Proved to be a pig to deal with at around 300rpm, so increased to around 670rpm:

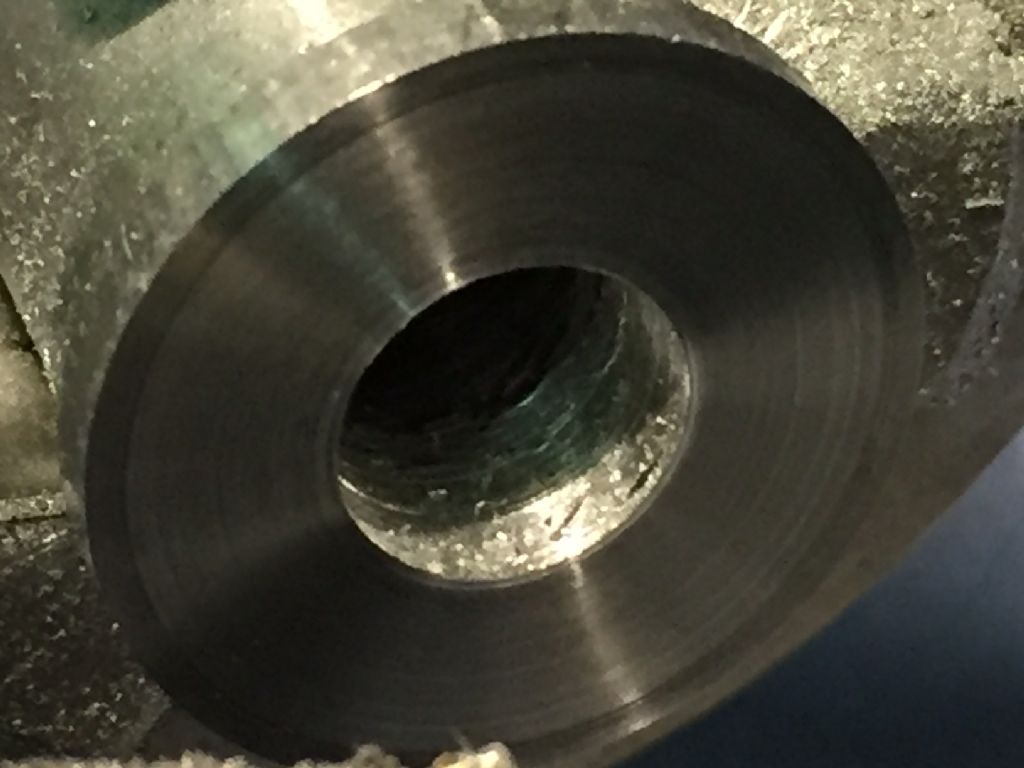

It was going reasonably at this speed, but very slow feed, and then the tip broke, possibly because I was a little nervous and failed to keep constant feed, resulting is some welding:

Didn't have time or chance to play with brass, but I am sure that it will behave similar to aluminium.

In short, was happy with results from first time experimental tests. Results may be different on different mini-lathes which have hi/low gear drives, and speeds will need to be played around with on such machines. Also, experienced users will have their own methods and get their own results. The guard was taken off for the purpose of taking pictures. Short videos were also taken on the phone for own reference. No time at present to put up on You Tube. If people want, will be happy to do so when I have some time.

Ketan at ARC.

Nick Hulme.

![dscn2324[1].jpg dscn2324[1].jpg](/wp-content/uploads/sites/4/images/member_albums/133289/530711.jpg)

![dscn2323[1].jpg dscn2323[1].jpg](/wp-content/uploads/sites/4/images/member_albums/133289/530710.jpg)