Posted by Swarf, Mostly! on 18/06/2021 09:49:12:

Hi there, again, Mark,

If you do decide to buy a new bull wheel and back-gear cluster, I suggest the following modification:

Drill a hole (say, 6 mm clearance) through the bull wheel diametrically opposed to the sliding gear segment. (While the bull wheel is off the mandrel this is more convenient than having to disassemble the lathe. If I were to need to remove my lathe mandrel and bull wheel for any reason, I would perform this same modification before reassembly.)

Then cut a length of square bar to span the head-stock casting and fit a 6 mm dowel in such a position that the dowel can be engaged with the hole in the bull wheel with the ends of the bar resting on the front and rear of the head-stock casting.

Should you, for example, need to unstick a stubborn chuck, fit the bar and dowel to the hole in the bull wheel. This will immobilise the mandrel without any excess sress being imposed on the teeth of the bull wheel or back-gear. The torque applied to the chuck will be transferred from the mandrel, via the woodruff key, to the bull wheel, thence to the dowel & bar and then to the head-stock casting.

It might be argued that drilling such a hole in the bull wheel would cause inbalance but I do not think this would be serious in an ML7.

Best regards,

Swarf, Mostly!

Hi there, all,

Those of you who are familiar with the ML7 will have immediately realised that part of what I wrote, above, is sheer bunkum!! A plain bar will not span the head-stock casting – the bull wheel gets in the way.

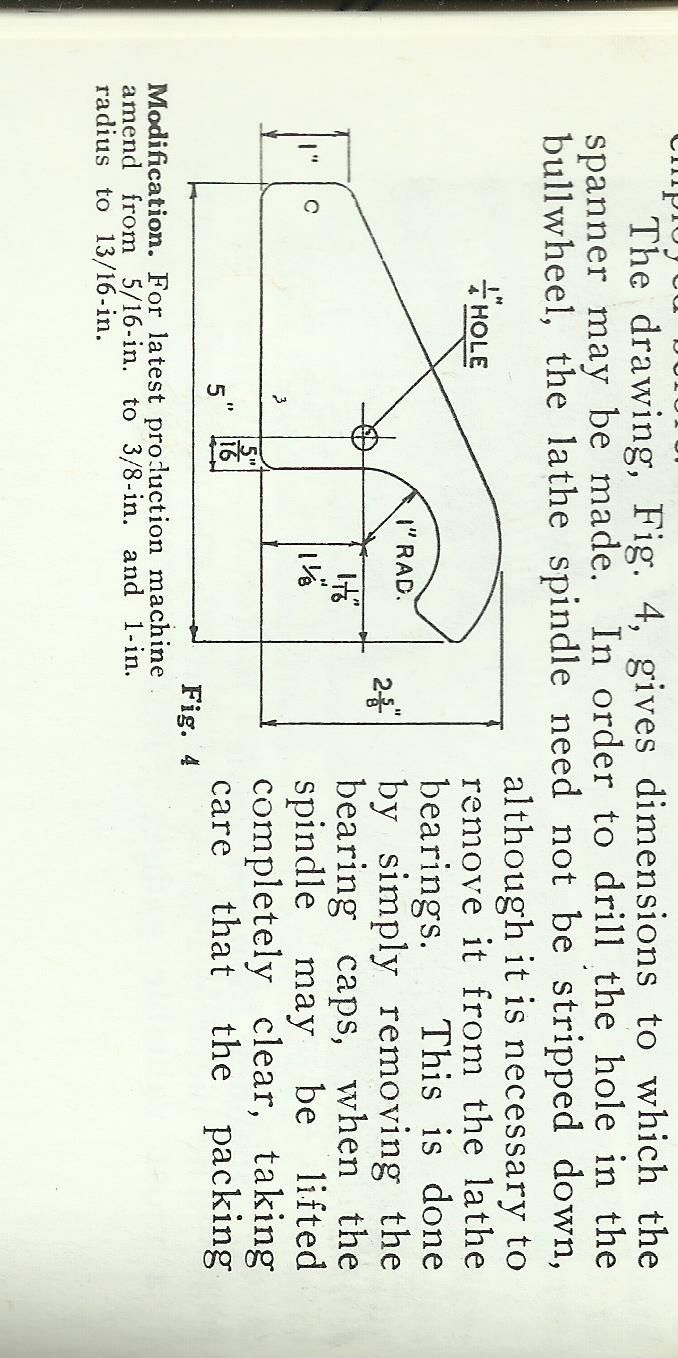

However, while I was searching for a new book to read to while away lockdown, what should fall out of the book-case but 'A Man and His Lathe' by Laurence Sparey, published by TEE. Browsing its pages, I found what my memory had half remembered. Here's a scan of part of the relevant page:

My suggestion had the dowel in the bar whereas Mr. Sparey puts his dowel into the hole drilled into the bull wheel. I have to confess I prefer his scheme. The photos in 'A Man and His Lathe' are rather dark so I didn't scan the relevant photo of the C-spanner in action. Does anyone know if the book is still in print?

I apologise for reviving such an old thread but I wanted to correct my error. I am embarrassed by the web-site's rendering of my scan – moderators, please feel free to re-orient and reduce size.

I wonder whether the original poster has solved his problems?

Best regards,

Swarf, Mostly!

noel shelley.