So I wonder if I can air some of the problems I had to see if I can find out where I went wrong.

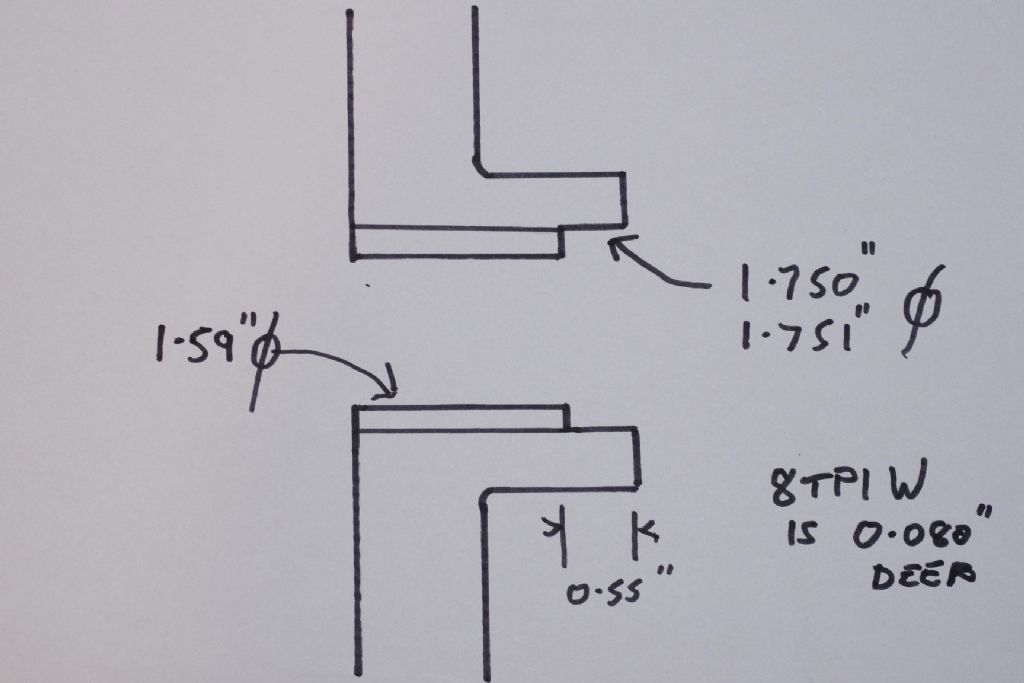

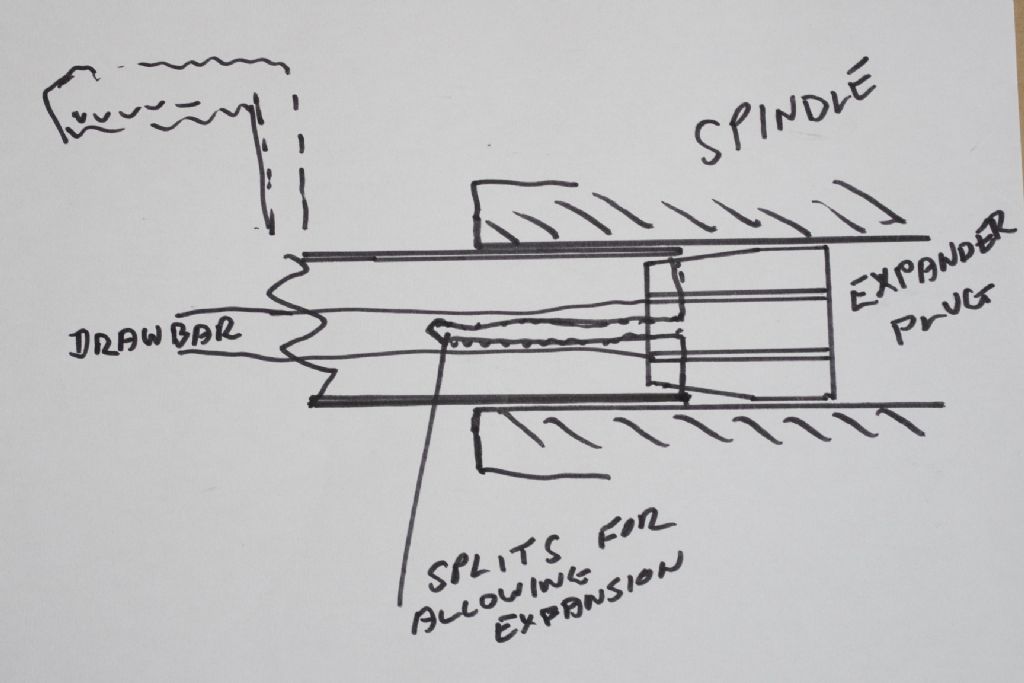

When the thread started to show on the counter-bore, the thread cut registered on the outermost edge of the boss (nearest the spindle in fitment) but didn't run along the full length of the counter-bore, which at the time I didn't understand.

I stopped at this point and reversed the plate and chuck, and the thread would start but go hardly any distance onto the spindle, so I reset, cut the thread a thou deeper and tried the fit again.

This went on for ages, with my trying to get the thread to show the full length of the counter-bore, and trying the plate on the spindle. With every pass, the thread would engage very slightly more, but nowhere near fully.

Eventually, I gave up this method and took a tiny cut off the counter-bore face and the plate screwed on instantly.

So but conclusion after all that is that maybe the counter-bore was slightly tapered?

Now I used the compound slide to machine the counter-bore, as its got a dial, whereas the carriage doesnt.

Is this a boo boo, as its the only way I can think that I could have got the taper.

In hindsight I realise I could have used the DTI to get the depth of cut from the carriage.

So, sorry for the long post, but its complicated (to me anyhow).

Anyone got any thoughts on that lot?

I've got another Boxford 1-1/2 plate to have another go but it'd be better to get it less wrong 2nd time around.

Cheers,

Jim

Edited By Jim Beagley on 01/06/2020 18:36:03

Edited By Jim Beagley on 01/06/2020 18:36:40

Edited By Jim Beagley on 01/06/2020 18:37:00

Edited By Jim Beagley on 01/06/2020 18:37:54

Jim Beagley.

. Remember, you are cutting backwards like when boring. So you should return each time to 80, or a bit more or the insert will probably break. Having the intended cuts written on a sheet of paper and crossing them off as you go is a help also. So the cuts would be as follows:

. Remember, you are cutting backwards like when boring. So you should return each time to 80, or a bit more or the insert will probably break. Having the intended cuts written on a sheet of paper and crossing them off as you go is a help also. So the cuts would be as follows: