Posted by Paul Ainsworth on 15/07/2018 09:19:22:

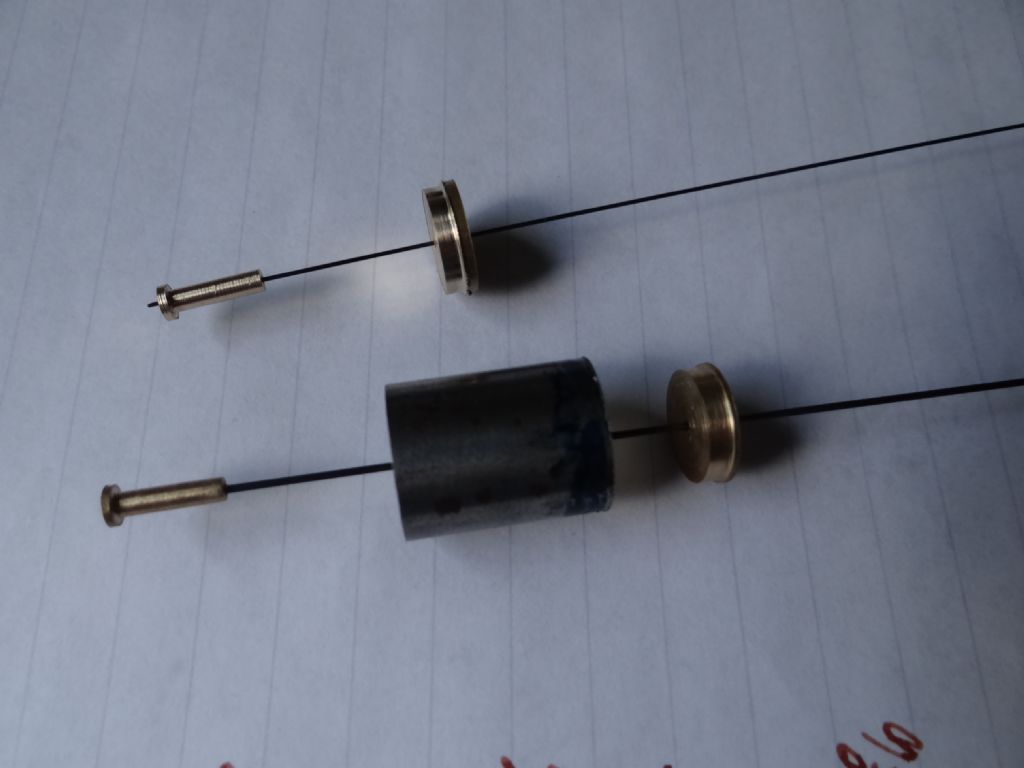

I have to drill and tap 3/32" brass rods on both ends. I've gone with M1.4 x 0.3 thread as the suggested 0-80 taps/dies are rarer than a rare thing, so I need to drill a 1.1mm tapping hole.

What speed? These are available 840/490/280/145/85/48

What feed? Constant push or pecking?

I have just finished a job in PB102 bronze on my Myford and in which I needed to tap 39 (thirty nine) M1.4 holes 3/16" deep. To be honest, it is not as difficult as it sounds. The most important thing is to start by centring lightly with a No.0 centre drill and use a new, high quality HSS drill. 1.1mm dia. is good for brass over a short length but, despite what the book says, you can get away with using a 1.2mm drill instead of 1.1mm for bronze. There will not be quite as much thread but they are strong enough for purpose. I have been told that 75% thread depth is still 95% efficient, so you are not losing much strength anyway.

It is also much better to never cut dry, always use a cutting oil and "3-in-1" with added PTFE will do the job for you. I drilled at about 800 rpm, with light cuts, relieving the drill frequently and tapped by hand, relieving the tap every two turns.

I have never tapped this small a size before but did all 39 holes with the same drill and the same tap and don't think you will have any problems either.

Kind regards,

Leszek

Paul Ainsworth.