Hello all

I suppose it's about time I show what I've been up to for the last few months, I know most of you don't bother with cleaning your machines down after use, but me and my dad do, its a bit fussy and pointless but hey ho! The only problem with the Myford is cleaning it down takes nigh-on an hour+. On the mini lathe the cleaning down process is quite easy because of the rear tray. so i decided to mock a rear tray up for the Myford.

Ideally I wanted it to fulfil certain requirements, these being;

-Not to block the plug sockets behind the belt tension lever, yet still permit the easy use of said lever.

-Still be able to use the myford cover

-Allow easy swarf clearance

-Look half presentable

-Be easy to remove

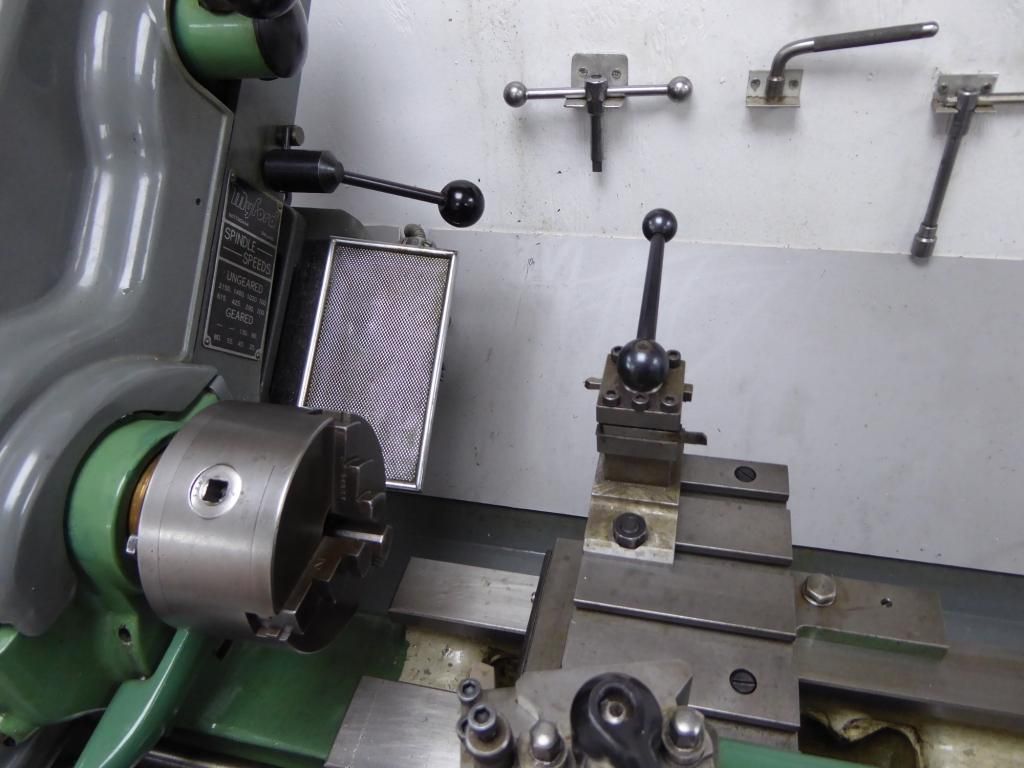

Here's what I came up with:

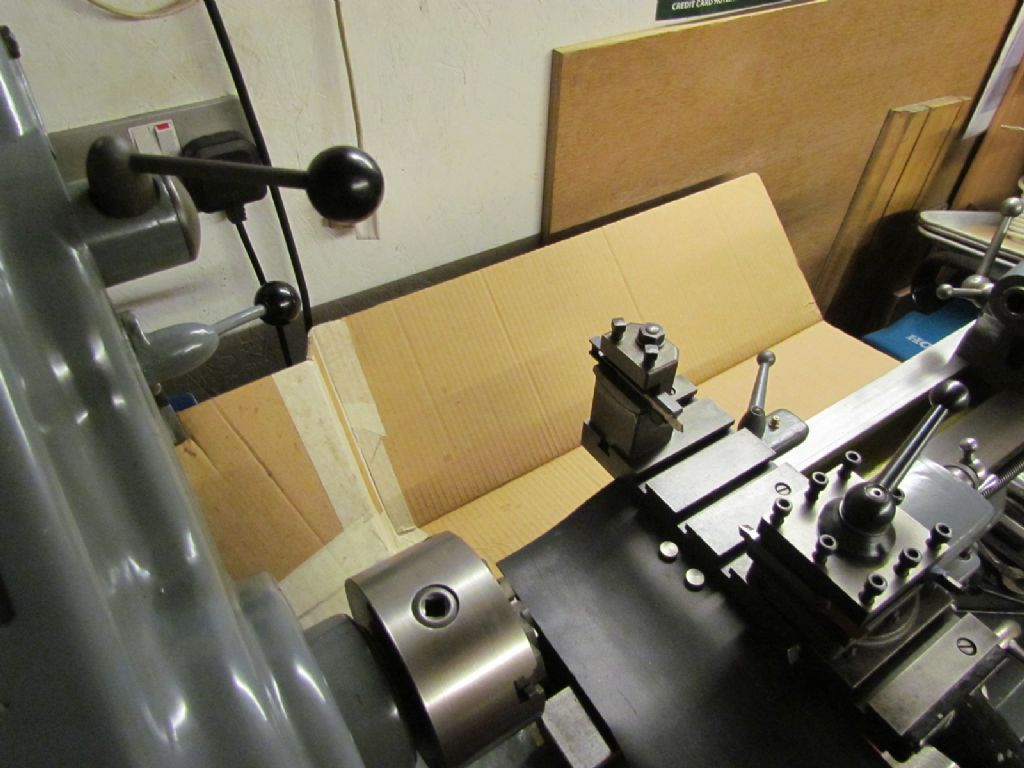

Plenty of clearance for socket and lever

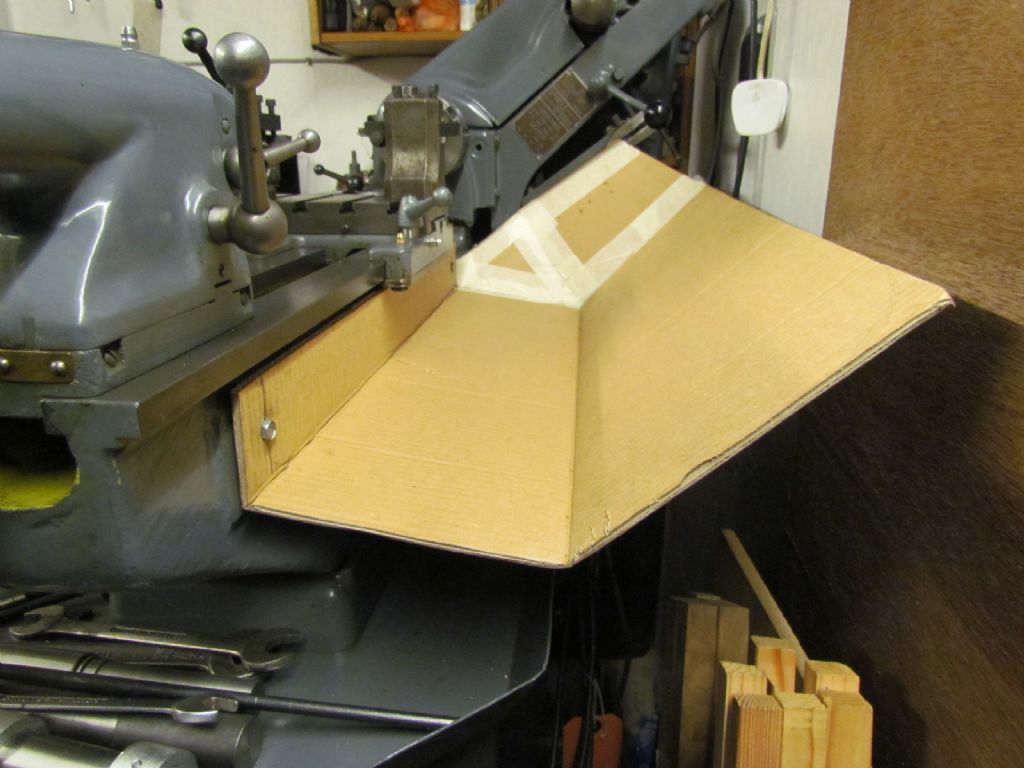

The Myford cover still fits

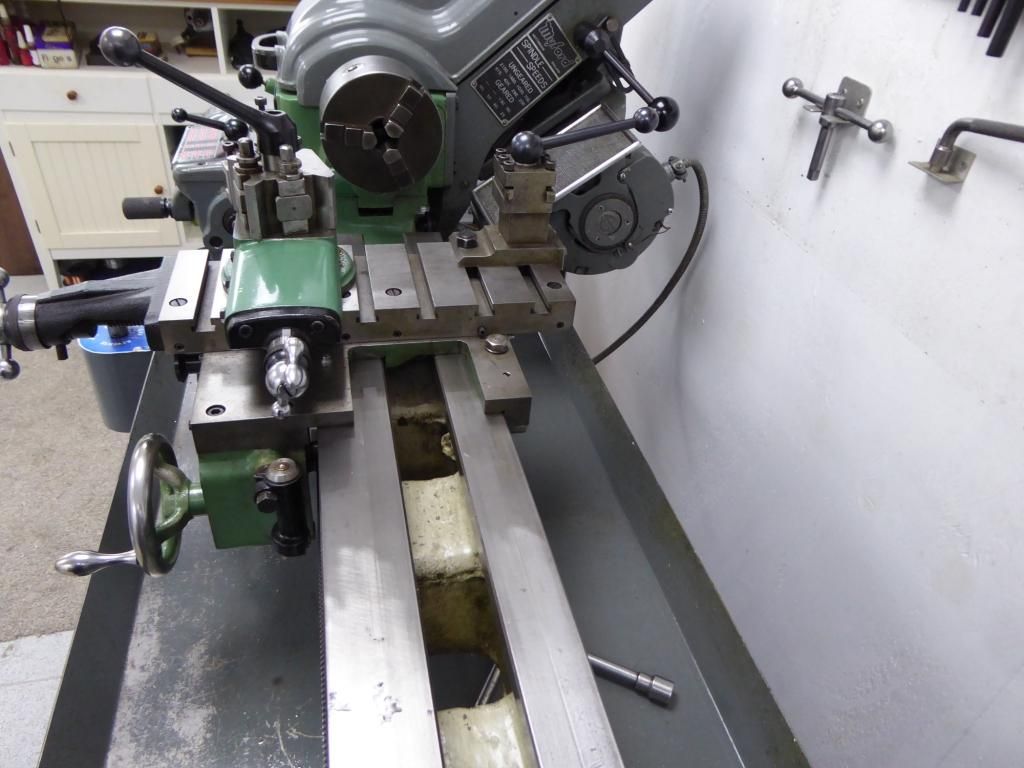

Swarf can just be brushed from the carriage into the tray, then into the awaiting dustpan.

View from the end showing how it's fastened to the rear of the bed using the tapped holes for the taper turning attachment etc. This also permits easy removal of said tray. Only 3 fixings needed.

The only bit that needs a bit of fettling, the swarf has the whole tray to land in and most of it ends up down this tiny little gap!

Doesn't look too horrendous either!

And it works!

We'll use it in its cardboard form to iron out any problems then it probably be cut out of aluminium. which then will rattle like hell!

Any thoughts and suggestions greatly appreciated

Thanks for looking

William

KWIL.