The coding on the reamer, such as H7, defines the expected tolerance that it would give. While this is of little interest to model engineers it is of great importance in manufacturing where interchangeability is a must.

I will give a simple description on how it works.

For example, we want a 10,00mm shaft which slides in a bush (a sliding fit is between a push fit and a nice rotating fit).

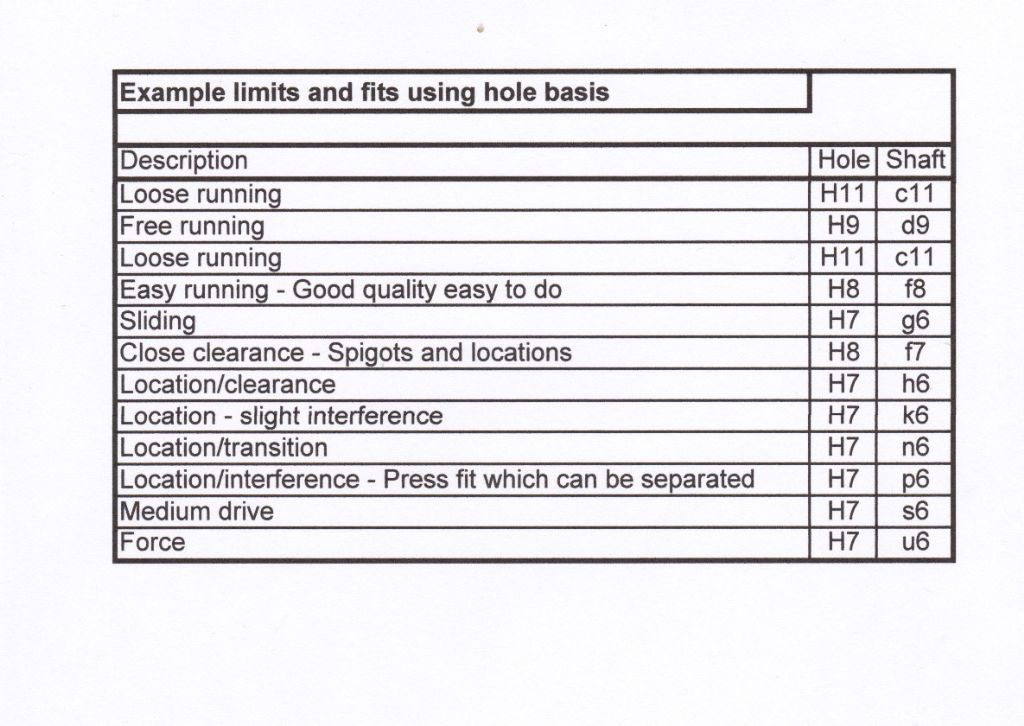

The established standard kindly gives a chart

which suggests a hole and shaft tolerance – H7 & g6 (upper case = hole, lower case = shaft). The number gives the machining process that will achieve the required tolerance with ease.

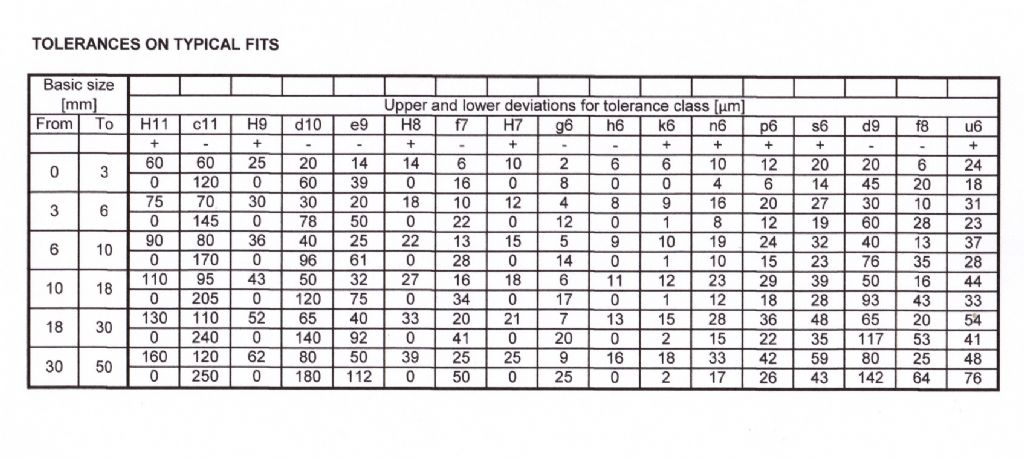

It shows that we should be able to achieve the tolerances by grinding, broaching, reaming, boring or tuning. Finally we need the tolerances and required dimensions.

The hole requires a tolerance of 0 to +18 μm and the shaft -6 to -17 μm. It follows that the dimensions are 10,000 to 10,018 mm for the hole and 9,983 to 9,994 mm for the shaft. A 10mm reamer marked H7 should give us the correct hole dimension.

Fits and limits can get horribly complex and, unless one’s interest was manufacturing engineering, there were usually better things to do.

JA

JA.

JA.