I was going to start a new thread about my newly acquired Beaver, I'm not contemplating a full restoration, more a clean up and repair job, but is seems sensible to just add to this thread and keep all the Beaver info in one place……..hope thats ok?

Rewind a few days, and i saw a Beaver VBRP advertised on Gumtree, it was cheap and local…….Tempting ! The only problem being space, my workshop is crammed in the corner of an oversize domestic garage, with a door that limits headroom when open.

Out with the tape measure and after some 'Man' measuring i convinced myself it was a goer, so me and a mate hooked up the trailer and set off to collect.

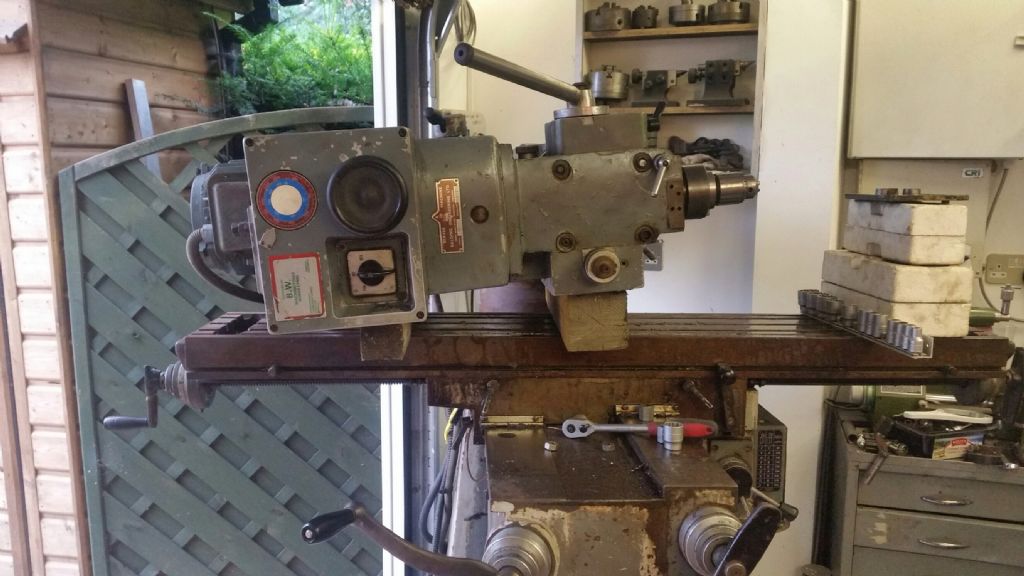

This is my unsuspecting universal mill before it was ousted to make room…..

The seller had a forklift and agree to load the mill onto my trailer, we decided to swivel the head down on to the table to lower the COG, there are 4 bolts to loosen, and then the head should rotate on a worm and gear, unfortunately it wouldn't budge more than a few degrees either way. after much faffing about we decided to undo the bolts completely and withdraw the head enough to clear the ring gear, this allowed the head to spin. we had a strap around the forklift tines to support the weight of the head.

After some initial forklift wheelie shenanigans, (heavy old thing) we eventually got her loaded up….do you think we had enough ratchet straps on

The journey home was uneventful, apart from it raining heavily and the mill spewing loads of oil everywhere, pity anyone following us. As it was late we stuck the trailer in my mates workshop overnight.

Today we brought her home, luckily my aforementioned mate has a bloody big tractor, with a home brewed crane on the back, which made short work of unloading, he dropped it right in front of the garage, and in ten minutes we had it shoved in place on steel rollers.

First job was to work out why the head wouldn't rotate, so i wound the table up to support the head and unbolted it completely to gain access to the worm and gear.

Once inside it was obvious what the problem had been.

Strange thing is, i can't see how this gear and worm could have ever worked together, think someone has had a fiddle before……

I decided that would have to be a job for later, so boiled the head back on minus the gears and set to manually rotating it back vertical…….bugger me its heavy! in the end i used a small trolley jack and loads of wooden packers to get me most of the way vertical, with the last 30 degrees done by brute strength.

Result…..it fits….and the garage door opens…..just !

Decided to have a few hours of peace, cleaning off all the swarf, oil and shite….first impressions are good, minimal backlash, and no visible wear to the ways….The table has a few battle scars, but nothing that's going to affect anything i do in the future. Interestingly it has piping for a one shot oil system, although no resevoir or pump are present, this may account for the good condition of the ways.

More updates to follow

Mark Guy.