I think you're probably on a hiding to nothing trying to use the Myford. I agree with Baz that slitting saws always run slightly eccentric. Another issue is that they can go walkies if not properly supported. Even on my Bridgeport slitting saws often don't cut true when deep slotting. On the horizontal mill they are fine, but it's a heavy old beast.

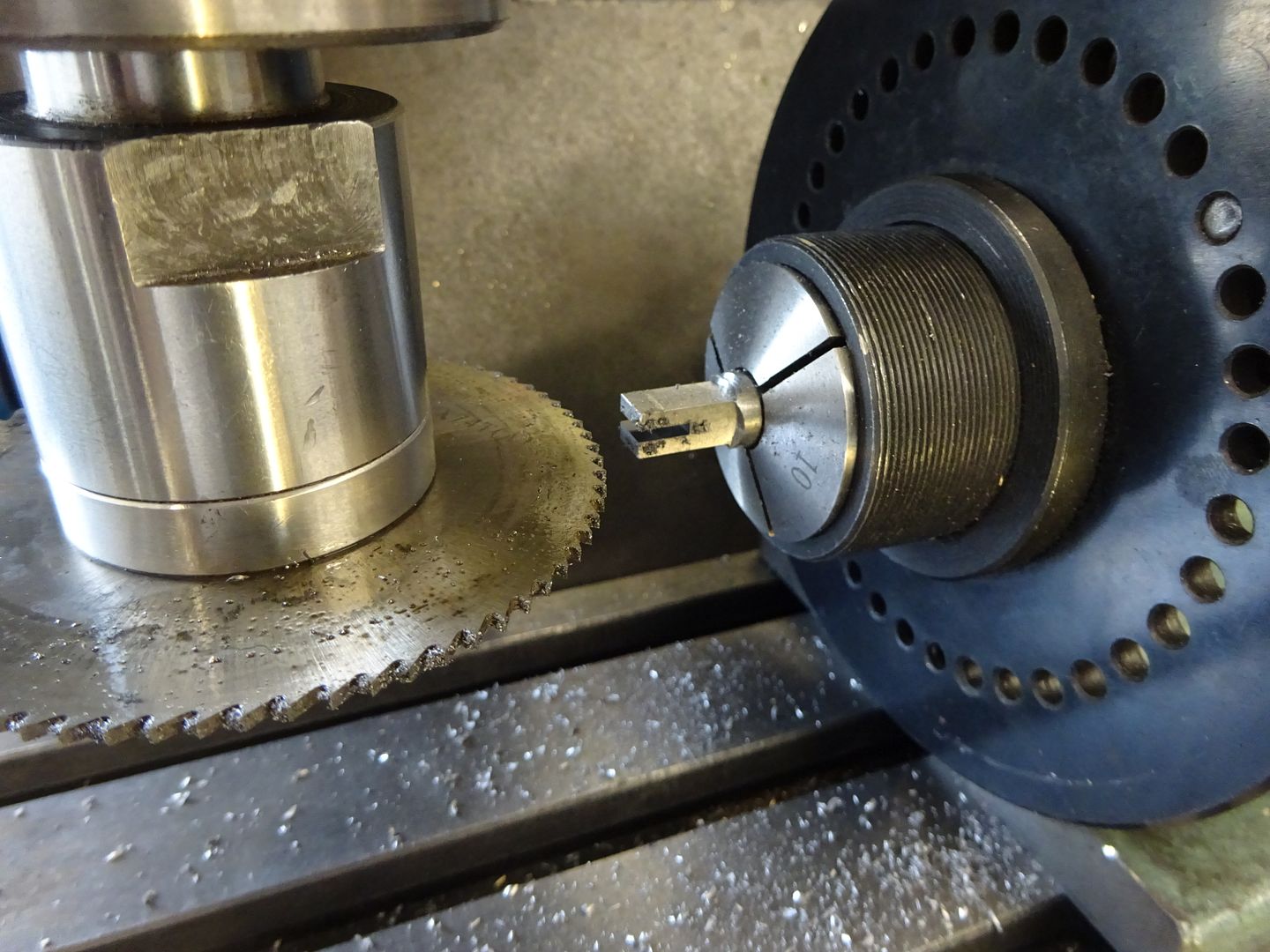

When I make clevises it's easier to use a slotdrill or endmill end on rather than use a slitting saw to make the slot. A problem with stainless steel is that some alloys work harden if you let the tool rub. An issue may well be that the Myford isn't rigid enough to take a decent cut per tooth to prevent work hardening. If I was going to use a slitting saw I'd use a coarse tooth one, as below, apart from the one bottom right:

The coarse teeth ones have a big enough gullet for the swarf to escape without jamming. Fine tooth slitting saws are intended for shallow slots only.

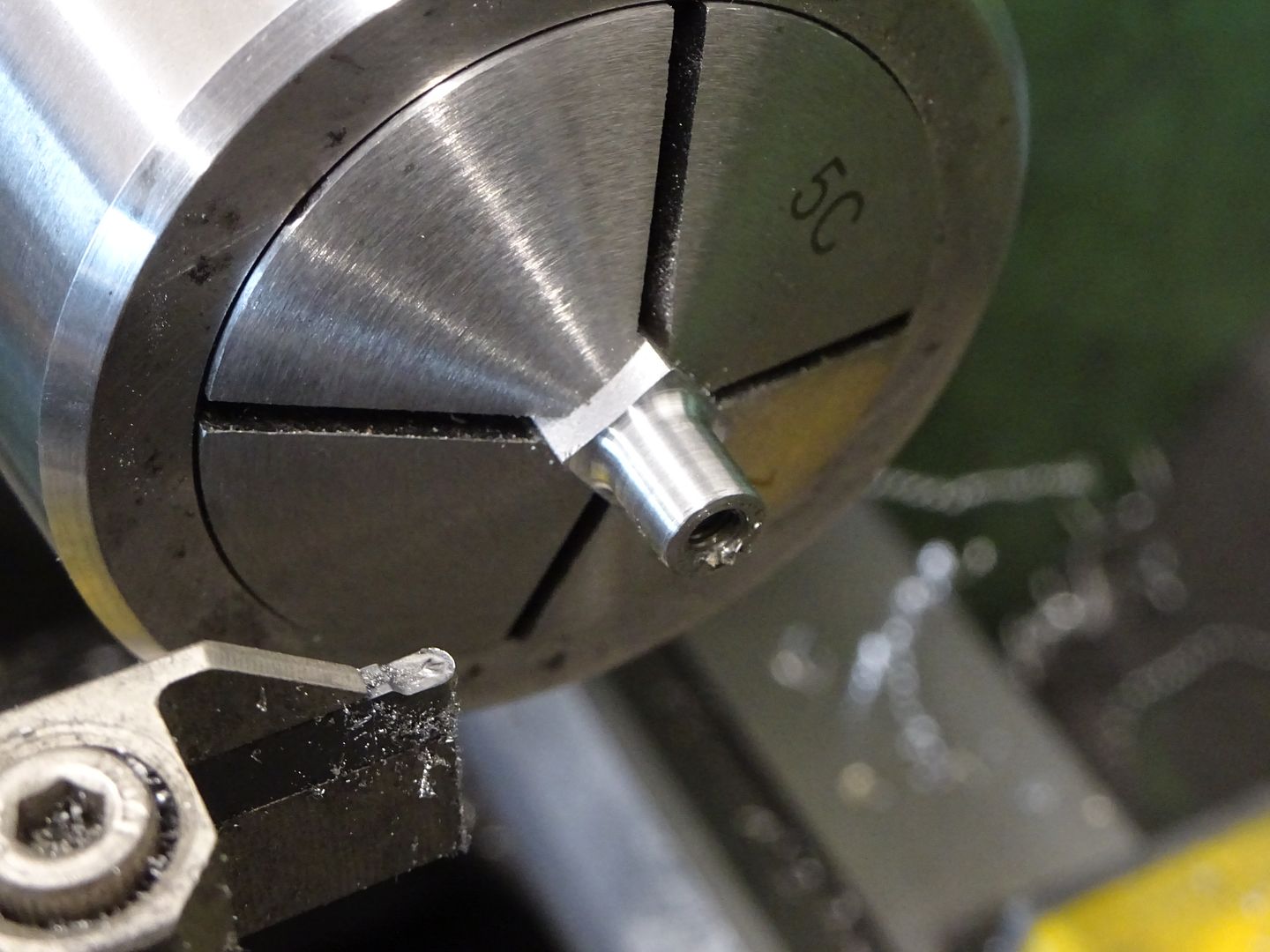

To summarise, forget slitting saws and use a slotdrill or endmill. Or drill out the waste and finish by filing. When making clevises I cut the slot first on a longer length of material and then turn the remainder using a split bush.

Andrew

Andrew Phillips 4.