Martin Cleeve (a pen-name of Keneth Hart) was a recognised authority on screw-cutting in the lathe. He was granted a patent on a swing-clear tool holder, which is another solution to speeding up screw-cutting.

Download a PDF version of Martin Cleeve’s article here.

Alastair Sinclair’s letter:

Enjoy more Model Engineer reading in the monthly magazine.

Click here to subscribe & save.

Dear Sirs,

I am pleased that you have decided to make the readership aware of the very excellent Metal Master Machine Tool in the February issue. I remember reading about this in the article by David Urwick in ME No 3480 January 1974 (a copy of which I still have) and thinking that there could not be a more versatile machine available for the model engineer.

I was particularly impressed with the screw-cutting system employed which featured the single-tooth dog clutch on the headstock mandrel to ensure perfect pick up of the thread being cut every time even at high speed and without stopping the machine, except when checking progress. David mentioned in his article that this system was based on that of the EXE lathe which originated the method and which first became available during the 1920’s.

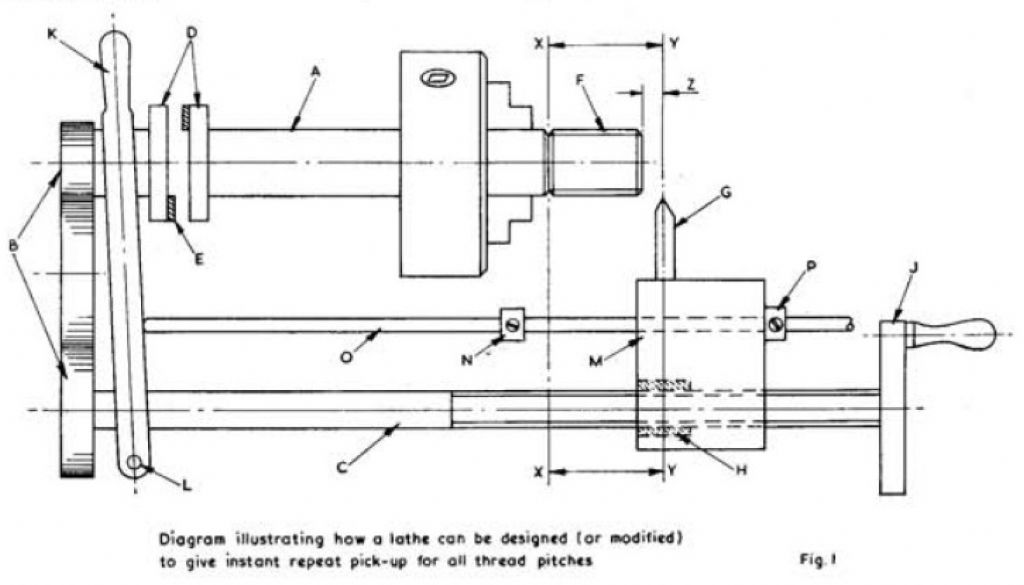

Now by far the most detailed and informative article describing the working principle of this system is given in ME No 3557 March 1977 by Martin Cleeves entitled ‘Screwcutting in the Lathe’ which goes on to extoll its particular advantages and to describe how he modified his ML7 to use this system by the introduction of a clutch on an extended output spigot of the tumbler reverse. He also gives advice on the cutting of metric threads using this and of multiple start threads which it seems it can do with considerable ease. There are no construction details of his clutch mechanism given but the photographs are good and no doubt there are Myford owners out there who would be keen to try this excellent method and design their own clutch details to suit.

I have to say that given the superiority of the EXE system which provides totally foolproof thread cutting, it is difficult to see why this was not adopted as the standard method of design for all screwcutting lathes thereafter.