The author now has 50 years’ experience in driving small, coal fired locomotives so it seemed to be a good idea to write some notes for others who have, perhaps, recently bought a locomotive or built a kit such as a Polly. These notes are intended to cover the operation of copper boilered locomotives such as those described by LBSC and Martin Evans. Covering scales from ¾ to 2½ inches to the foot and gauges of 3½ to 7¼ inch and, whilst allowing for a large 5 inch narrow gauge locomotive, they should still make sense for 2½ inch gauge, although I don’t think I’ve ever driven one. They are not intended to cover steel boilers which require water treatment to preserve them. Additionally, the writer lives in a soft water area where a 40-yearold copper boiler, recently scrapped with worn out tubes, was found to be very clean internally, showing negligible deposits. In accordance with standard practice, this article has been quality reviewed by other experienced drivers/ model engineers.

When raising steam, a blower in the chimney will assist the fire.

Enjoy more Model Engineer reading in the monthly magazine.

Click here to subscribe & save.

Copper boiler testing

Please note: This section is not intended to be a treatise on copper boiler testing but is included merely to provide you an idea of what to expect.

It is assumed the boiler has passed hydraulic and steam tests and is appropriately insured before steaming. To obtain a valid test for insurance, you will need to be a member of a model engineering society. Testers appointed by societies work under the rules developed by the Northern Association of Model Engineers (NAME) and the Southern Federation of Model Engineers. The testing is performed at the discretion of the boiler tester and is initially to twice working pressure, then to 1.5 times working pressure on re-test. Currently the hydraulic test is valid for four years. Following a satisfactory hydraulic test and award of a certificate, a steam test is performed. This is mainly to check that the safety valves are capable of releasing sufficient steam produced by the boiler, with the steam blower – or jet – on hard, so as to maintain the pressure within the limit of ‘working pressure’ (as indicated on the engine’s pressure gauge with a red line). The steam certificate is valid for one year. If you are considering a commercial boiler it must be ‘CE’ marked if manufactured after 29 May 2002 or it will be considered to be a non-compliant boiler and effectively scrap metal. This ‘CE’ requirement has been brought about by the introduction of an EU Pressure Equipment Directive.

What is in the boiler?

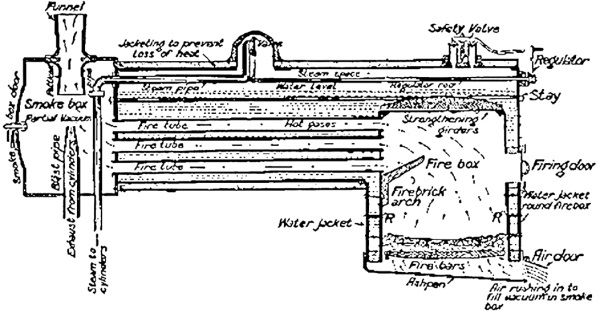

I have included a cross-sectional drawing representative of a full size, 19th Century locomotive boiler with a conventional locomotive firebox. The firebox crown is shown above the label ‘Strengthening girders’.

Model locomotive boilers are broadly similar in layout with some notable exceptions:

- The firebox is generally too small to contain a brick arch.

- Many boilers have stays connecting the outer firebox to the inner firebox crown, above the label ‘Strengthening girders’

- Many models and more modern full sized locomotives are fitted with a superheater, whereas this boiler supplies saturated steam to the cylinders.

Steam is said to be saturated when it is at the same temperature as the water from which it evaporated; superheated steam has been heated to a higher temperature away from the source water.

In practice, a superheated boiler is fitted with several large flues in place of the upper firetubes and the steam from the regulator is conducted towards the firebox and back to the smokebox through hairpin shaped tubes before passing to the cylinders. There are other designs of superheater, including concentric tube, ‘radiant’ types that extend across the firebox crown but the principle remains the same. This heating reduces the tendency of the steam to condense in the cylinders and increases efficiency. In full size practice coal consumption was of major interest to the companies involved but this is less important with the small quantities we burn. However, we are trying to do work by expanding gas in the cylinders, so if some of our precious gas condenses to liquid, vital performance will be lost!

Many clubs require the fitting of a spark arrester for public running, to reduce the risk of burns to passengers. This can often be conveniently arranged with a sheet of 1⁄8 inch square hole mesh fitted diagonally from the front tubeplate, above the top tubes, to just below the smokebox door. Do not worry about covering the superheater flues as they are unlikely to pass cinders unless you are very heavy handed with the regulator. There will need to be a cut-out for the blast pipe. Under no circumstances allow the exhaust from the blastpipe to pass through the mesh as oil will quickly cause it to choke up. Be aware the fitting of such a spark arrestor will have a slightly detrimental effect on the draughting by adding friction to the passage of flue gases.

Your first duty is to the boiler

Without wishing to cause hysteria, your paramount duty to a locomotive in steam is to keep the firebox crown covered with water. The crown is the top heating surface of the firebox immediately above the fire. Naturally, the steam pressure in the boiler acts upon the firebox crown externally, attempting to crush the firebox and also to expel it downwards from the boiler. The effective water level can be altered by the gradient of the line and particular care should be taken when moving an engine from elevated steaming bays that have a steep slope to ground level track. In this case, position the engine so the firebox will be at the lower end when on the slope before raising steam. Boiler safety is of utmost importance in view of the large amount of energy stored in the form of superheated water. The boiler water, which is heated above its atmospheric pressure boiling point, will flash-boil to a very large and destructive volume of steam should the boiler suffer structural failure precipitated by too low a water level. You may be interested to know that water in a boiler at 80 psi has a temperature over 160 degrees centigrade. The abbreviation psi is used here to represent ‘pounds per square inch’ which is the gauge pressure, rather than the absolute pressure, as the (approximately) 14.7 psi of atmospheric pressure is shown as zero on the gauge.

A word on couplings

It won’t go amiss to say a few words on coupling things together. My own club uses flat steel strip couplings. Coupling pins have an R clip through the end or are fitted with a C shaped spring retaining clip which hooks back over the end of the pin. Whichever type you use, make sure they cannot come out. When connecting things together, make sure the links are parallel with the frames when on a straight; this is important on multi-gauge track, driving cars usually have a multi coupling frame at both ends to account for this sort of thing. Some clubs also use an additional chain or wire link to prevent a runaway in the event of coupling failure.

Preparation

Now let us talk about preparing the engine for a run. You will need lubricating oil, steam oil and clean water. An airtight container of fire lighting charcoal soaked in paraffin or white spirit (airtight as you wouldn’t want the paraffin leaking in your car boot) and a supply of suitably sized anthracite. The latter should be as free from dust as possible; some is bagged wet with adhering dust such that it really requires washing and drying before use. Dust will pass through the tubes and add to the accumulation in the smokebox, quickly spoiling the steaming properties of the boiler and it won’t do much for your complexion either! It is also important that the coal size suits the engine; the 3½ inch gauge will probably steam well on grains with a 7¼ inch needing lumps around ¾ inch diameter. The idea is to maximise the surface area available for combustion without choking the airflow through the firebed. Should you fire with excessively large coal, steaming will be impaired as a large volume of cold air will pass straight through the fire without taking part in the combustion process. Within reason, fine division of the coal increases the surface area available for combustion and heat production but too small and the particles will choke the airflow. You will also need a means of drawing the fire (a blower), an electric fan and power source or other device powered by compressed air, plus a driving trolley and suitable couplings.

Couple the engine to the tender, if fitted, and connect any water pipes present, preferably on a steaming bay away from the main running line. On a tender engine you are likely to find flexible connections for injector water feed, axle pump water feed, an axle pump bypass return and a pressure connection for the emergency hand pump.

Beware of a watering can or hose which may have accumulated debris since it was last used; give it a rinse out before using it to fill your tanks. Close the regulator, close any open boiler drain cocks/blowdowns and the blower valve and fill the tank(s) with clean water. Open the cylinder drain cocks if fitted. Put the valve gear into mid-gear by positioning the reverser in the middle of its travel – we don’t want a runaway. I have been asked how you tell which way the regulator opens; if you ensure the valve gear is set in mid-gear as just described, you need not be too concerned until you have some steam pressure. Steam leaking from the open drain cocks will betray an open regulator as pressure builds. If there are no drain cocks to tell tales there could possibly be a slight blow up the chimney from the blast pipe as pressure builds and/or condensate leakage from the piston rod glands. Otherwise you’re on your own with the reversing lever, as any movement from mid-gear will result in the engine starting; so if you still don’t know which way is open, it is prudent to leave the reversing lever well alone until you are safely seated, ready to drive away later. (Editor’s note: application of the engine brake might be prudent if the engine is situated on anything other than perfectly level track – any may be wise in any case.)

Fit the ashpan and grate if not already present. Familiarise yourself with the fixing of the grate so you know how to drop the fire quickly should a water feed emergency occur. Fill the boiler with water so the firebox crown is covered. This may be done in different ways: with the hand pump, by pushing the locomotive up the track with the bypass valve closed or by removing a safety valve and using a funnel. Check the hand pump by giving it a few strokes if you haven’t used it to fill the boiler. You will feel the resistance and hear the clacks rattle if it works. If the inlet valve has stuck, indicated by the pump handle springing back under the effect of vacuum, release it by draining the cold water from the tank and adding some hot water from a kettle.

You should be aware that although it is good practice for the boiler to have its gauge glass positioned such that water showing in the glass means the firebox crown is covered, this is not always the case. If you have not built the locomotive, do not take this for granted. Look at the boiler backhead and you will be able to see the ends of the longitudinal stays which support the flat area above the firetubes and superheater flues; the lowest of these pass just over the firebox crown so give a good indication of the minimum permissible water level. You can see one of them clearly marked ‘Stay’ in the drawing, below the regulator handle. This stay idea is not needed for a marine firebox such as found on a Sweet Pea as you can see the circular end of the firebox tube at the backhead. A hollow (tubular) stay is often used to route steam for the blower to the front tube plate in the smokebox. Do not be over enthusiastic with the water as the level will rise as steam is raised. A glass half full is usually sufficient to light the fire if the gauge is positioned correctly on the boiler. At the temperature associated with an 80psi working pressure, the water will have increased in volume by about 10%. Top up the tanks again if you have used this water supply to fill the boiler.

Lubrication

It would now be wise to ‘oil round’ before considering a fire, covering the axle boxes and horns, the motion work and paying attention to the highly stressed little ends in the crossheads, the axle pump (if fitted) and the eccentric sheaves if you have inside gear. Don’t forget the tender axleboxes if you’ve got one! Top up the mechanical lubricator(s) with steam oil. Treat any mechanical steam water pump lubricator to steam oil and oil any exposed motion, drain the condensate and refill with steam oil if a displacement type is fitted.

Steaming

1. Fire lighting

Some people use wood, some fire-lighters but the writer prefers charcoal soaked in paraffin or white spirit. On no account use methylated spirit – the flame is virtually invisible in good daylight and you will surely set fire to your charcoal tin with a burning shovel! Charcoal burns hottest, to give you a good fire quickly, and produces less eye-stinging smoke. Broken charcoal briquettes as used on barbecues can also be used to good effect in place of lump charcoal.

Check the position of the bottom row of tubes by looking through the firehole door and make a mental note of the level.

Feed the firebox a good layer of soaked charcoal to cover the grate about an inch deep. Fit the electric or other blower to the chimney and turn it on. Check the water level is okay, then set fire to a shovelful of soaked charcoal and feed it carefully into the firehole. You may need to partially obstruct the outlet of the blower with one hand to avoid the flames being extinguished by the strong draught. If the fire doesn’t take hold, try again, noting the last point and the fact that the lighting shovelful may need to be quite wet with paraffin. Allow the fire to spread around the charcoal for a few seconds before closing the firehole door.

Feed the fire with charcoal once it is well alight; it doesn’t matter if you feed dry charcoal once the fire is well established; this will minimise the white smoke and save you money. Close the firehole door after each addition. Continue stoking the fire steadily with charcoal until the top of the fire is just below the level of the bottom row of tubes, which you memorised earlier. Allow the fire to burn through, top up with a little more charcoal before starting to feed coal in small quantities. If you hear a lot of spitting and popping and are getting showers of sparks from the blower at this stage, the draught is probably excessive. It is better to reduce the draught and take a few minutes longer to raise steam than to stress the boiler by forcing it too hard. This is more important with larger sized boilers than say a ¾ inch scale, 3½ inch gauge Titch. Full size boilers have to be steamed very gently; as the firebox end could be very, very much hotter than the front tube plate area, causing immense stress to the boiler if forced. As the lighting charcoal burns away, continue adding coal to maintain the level of the fire. As soon as the boiler pressure reaches around 30 psi the electric or other blower can be removed and the locomotive’s own steam blower will take over. Be careful not to burn yourself as it will be very hot and careless handling could cause you to drop it on your engine. Leave an electric blower running for a while to reduce the amount of heat soaking into the unfortunate motor. Remember the steam blower operates via an adjustable valve which controls the draught; you will not need a strong blast to pull the fire up, increasing the pressure steadily. It is common practice to wave one hand over the chimney of a model to feel the draught intensity whilst adjusting the steam blower valve with the other. At this point you will probably become aware if the regulator isn’t closed as you may have difficulty in raising much pressure and unexpected steam may be issuing from the drain cocks, if fitted, or chimney. A quick adjustment of the regulator position is quite safe as long as the engine remains in mid gear.

As the pressure increases, maintain the level of the fire by adding coal, keeping an eye on the pressure as it approaches safety valve release pressure. Check that the safety valve opens at the correct pressure and releases any further steam produced and not allow working pressure to be exceeded. This quick DIY steam test is for the driver who wishes to continue his hobby without Divine Intervention! Note that larger engines are equipped with two safety valves, which should be set to lift sequentially; they should lift in order but the principle of pressure release remains unchanged.

Once satisfied with the safety valves, you will need to keep an eye on the water level, replenishing the boiler with the hand pump, steam pump or injectors as available on the engine. It is important to check your means of boiler feed at this stage before much water is lost. Of course the axle pump can only be checked whilst under way but these are reliable devices when compared with injectors in the smaller sizes.

It would be wise to blow down the gauge glasses, briefly, to clean them and check the water level resumes position quickly, indicating there is no blockage in the fittings, which could cause misleading water readings. There are single and three cock water gauges, the former, fitted to smaller locomotives need no explanation but the drill for the latter is as follows.

- Close the two cocks in the passages communicating with the boiler and open the drain – the water should empty quickly.

- Open and close the top cock with the drain still open – steam should blow through.

- Then open and close the bottom cock with the drain open – a mixture of steam and water should blow through.

- Finally close the drain and open the other two cocks and the water level should re-establish quickly.

The hand pump needs no further explanation but the injector is worth a word or two. Start the injector by turning the water supply on, then opening the steam valve. Assuming the injector picks up, the water flow can be reduced to just stop the overflow from dripping. Increasing the draught of the blower will help compensate for the steam used and the influx of pressure-reducing cool water. To stop the feed, turn off the steam and then the water. Be aware than an injector will not feed warm water so tank engines need a cold supply fed from the driving trolley. Injectors have a definite range of operation pressure and will not feed below and above a certain pressure.

Adjust the draught level to a gentle blow to maintain the fire and pressure without causing excessive waste by violently lifting the safety valves.

If you have a mechanical lubricator fitted with a hand wheel it is sensible to rotate it by hand about 20 turns, this will ensure the clack or non-return valve is primed with steam oil and less likely to cause a blow back into the oil tank.

Transport the locomotive to the running line and couple securely to a braked driving trolley and you are ready to climb aboard and start driving.

Starting out

Open the drain cocks (if fitted) and ease/wind the reverser into full reverse gear (if traffic conditions permit reversing), leaving the blower open for the time being. Release the brake and gently ease the regulator open and travel a few yards in reverse to clear the condensate from the cylinders. Close the throttle smartly if she slips, before opening again carefully. Starting in reverse reduces the chance of you receiving a hot oily shower and is particularly useful on smaller locomotives if drain cocks aren’t present. Change to full forward gear and start forwards, closing the drain cocks after say thirty feet. The blower may also be closed as the exhaust blast should now maintain the fire but with a light load a little blower may be required to maintain pressure. Only experience will tell. Be aware that you may have set off with a quantity of charcoal left under the coal fire – this will burn away suddenly under strong exhaust blast, leaving you short of fire. Once the locomotive is up to speed, the valve gear can be ‘notched up’ to reduce the distance the pistons have travelled down the stroke, before steam admission is stopped, economising on steam. Compensate for the reduced power by opening the regulator more. It is full size practice to drive with regulator wide and control speed by varying the cut-off once under way on the main line. This is usually impractical on our tracks but ‘notching up’ is still good practice and a source of driver satisfaction. It is wise to take it steady with your speed, as excessive regulator opening and the consequent blast will hasten the build up of ash/cinders in the tubes and smokebox cutting short your run.

Be aware the chimney should not be dry and should have traces of black steam oil – this will confirm the lubricator is working.

Keep an eye on the fire and water level, firing should be little and often to reduce the effect of black coals in the furnace. If you have an axle pump, check the position of the bypass valve. Closed gives maximum boiler feed and fully open gives none at all with an infinite variation between. Many locomotives are arranged so the end of the return pipe is visible under the edge of the tank or tender filler, so the action of the bypass can be checked visually. Aim to adjust the feed level to maintain a steady level in the glass. If your engine has a steam pump it’s merely a matter of opening the control valve and regulating to a suitable speed once the condensate has cleared. The operation of an injector has already been described. The writer finds the injector very useful whilst stationary on the smaller locomotives. However, although more challenging, it is quite possible on a 3½ inch gauge, whilst under way. It can be a source of driver satisfaction if you manage it on the move but this is routine with larger scales.

You can then carry on, subject to signals, coal, water and oil supplies. When coming to a stand you will need a touch of blower to maintain the fire. Open the drain cocks, place the engine in mid gear and apply the brake before dismounting. You will find that small locomotives can reel off laps without stopping, other than to replenish coal and water, if they are well driven and in satisfactory condition.

With the locomotive in continued operation you will need to oil round periodically and to check the level in the cylinder lubricators. Don’t go wild with the oil on the motion for it may find its way on to the rails. As mentioned above, the chimney top should show traces of steam oil if the lubricator is working correctly; should you end up covered in oil, take steps to reduce the feed. You will need to rake the fire periodically to break up any clinker that forms and to clear the ash pan to maintain airflow. Don’t go mad with the rake as anthracite is prone to shattering, choking the fire with small particles. With extended, hard operation such as found on a society public running day, it may prove necessary to take the locomotive out of service for a short while the smokebox is cleared of cinders and the bottom row of tubes are swept. Be careful where the abrasive ash goes – a piece of card can be used under the smokebox door to collect the cinders and protect the ‘works’ and paint. Do not use a bristle fluebrush to sweep the tubes while there is still a fire in the boiler – you will soon have a wire thing and a bad smell. Don’t ask how I know!

After the run

Withdraw from the running line to clear the road for other drivers and adopt the following procedure on the steaming bay.

Fill the boiler up to near the top nut on the glass by a convenient means and use the blower to raise the pressure close to safety valve lifting pressure, then close the blower and drop the fire. Be careful of the hot coals, some societies provide troughs to catch the cinders. It may be helpful to disconnect your tender at this point, as you have no further need of feed water. Open the boiler blowdown valve and allow the contents to escape. Filling the boiler beforehand and raising the pressure should achieve maximum dilution of any dissolved matter and give the best chance of eliminating it from the boiler. With a copper boiler it is best to drain fully as a scale, fitting corrosion and frost prevention measure, also drain any water tanks as there is bound to be leakage in storage, which will promote undesirable general corrosion of your pride and joy. Leave all boiler valves and drains very slightly open to prevent them seizing when the engine cools down. Open the smokebox door and remove any cinder residues, then sweep the flues with a suitable diameter fluebrush. The writer believes the tubes are easier to sweep whilst the boiler is still hot. All that remains is to clean the engine externally, for which turps substitute, white spirit or paraffin is useful, followed by a wipe of clean oil. The author has found that smaller injectors fitted to 3½ inch gauge respond well to being removed from the locomotive after running, having the water blown out with a puff of air and dry stored in a suitable container for the next run but take great care not to lose the cones! This practice eliminates possible corrosion of the delicate cones as there is nearly always some water left in the pipework. Your injectors will appreciate an occasional bath in a hot solution of citric acid to keep them deposit free.

Operational problems

Poor Steaming: –

- Check smokebox door is closed and sealing properly.

- Is the pipe sealing secure where the steam and exhaust pipes exit and enter the smokebox?

- Is the coal of good quality? Some has been found to shatter into small pieces, choking the fire.

- Is the fire clinkered? Give it a good rake out.

- Is the ashpan blocked with ash?

- Do the tubes need sweeping? The bottom row are most prone to blockage and have a disproportionate effect on the production of steam.

Not pulling well: –

- Are all the brakes off? Hand brake, carriage brakes and engine brakes could all cause this.

- Lubricator failure causing increasing cylinder friction.

- Are the drain cocks closed?

Injector troubles: –

- Overflow blowing steam/ water when all valves are closed – leaking clack valve, possibly due to dirt or scale under the valve.

- Won't pick up – is there enough or too much steam pressure? Is the feed water hot? Are the cones clean? Is the injector water valve allowing air into the water line?

Public running

It is best to practise your driving s kills on ‘fun running’ or ‘Club’ days without the pressure of a queue of would-be passengers. If you need a load, you will no doubt be able to rustle up some members as ballast. As you become more confident, seek some guidance from an experienced club member regarding your own local practices. (Editor’s note: Most clubs operate a ‘licence’ system where a driver has to prove his or her competency, not only in engine management but also in knowledge of the track, its signalling and safety features, before being allowed to pull passengers.)

kills on ‘fun running’ or ‘Club’ days without the pressure of a queue of would-be passengers. If you need a load, you will no doubt be able to rustle up some members as ballast. As you become more confident, seek some guidance from an experienced club member regarding your own local practices. (Editor’s note: Most clubs operate a ‘licence’ system where a driver has to prove his or her competency, not only in engine management but also in knowledge of the track, its signalling and safety features, before being allowed to pull passengers.)

Check list

Before lighting the fire: –

- Apply brakes if fitted

- Put valve gear in mid gear

- Oil all moving parts

- Check/replenish all mechanical lubricators with steam oil; drain/replenish displacement lubricators.

- Fit the ashpan and grate, check the smokebox door is closed properly.

- Close any open valves such as blower, blow down and injector steam valves.

- Open the draincocks if fitted

- Fill water tanks or tender, after connecting any water pipes.

- Fill boiler with sufficient water to adequately cover the firebox crown sheet.

- Replenish tanks

- Check operation of hand pump.

- Cover the grate with about inch of pre-soaked charcoal.

- Gather together fire irons, auxiliary blower, soaked charcoal and a match.

- Check the water level, turn on the blower and light the fire.

After lighting the fire: –

- Adjust the blower draught

- Feed the fire charcoal to establish a depth of fire.

- Switch to coal and feed little and often.

- Once you have about 30 psi change to engine’s own steam blower.

- Raise pressure gently, controlling the blower as the pressure rises.

- Check the operation of the safety valves.

- Check the operation of injectors and or steam pump if fitted.

- Prime the mechanical lubricator by turning the handle, if this is possible.

Starting out: –

- Couple adriving trolley securely.

- Check the draincocks are open if fitted.

- Select reverse gear if travelling backwards is possible.

- Ease the regulator open and travel a few yards backwards to avoid the oily shower of condensate.

- Stop and select full forward gear.

- Ease the regulator open, closing smartly if she slips before trying again more gently.

- As you gather speed close the blower and notch up the gear.

- Keep an eye on the water and fire, controlling the supply of water and coal in a little and often manner to avoid loss of pressure.

- If you have a boiler water feed emergency, stop and drop the fire; better a red face than a ruined boiler or worse!

Stopping

- Crack the blower open close the regulator.

- Open the draincocks if fitted

- Apply brakes and put valve gear in mid-gear when at rest and check these before dismounting.

- Don't forget – you shouldn't leave a locomotive unattended, this is particularly important in the smaller gauges due the low volume of water in the boiler.