Posted by Bob Worsley on 29/08/2021 10:54:04:

Interesting. Just reading old copies of ME and around 1981 there are endless letters (remember those?) about how naff the Myford oiler is. This was a pump action type that you just push onto the nipple, not lever action. My Harrison also came with a similar oiler and never managed to get anything out of it.

In issue 3666, October 1981 there was a letter describing why these oilers are so naff. The basic reason is that they should use grease, thin grease, not oil. A grease type pump action oiler is different to an oil type pump action oiler.

The grease to use is BP Energrease PR1. This grease is almost translucent, and a sort of reddish brown colour. I am sure I had a tin of this bought decades a go but can't find it. It will settle out if just left so will need a good stir.

It would seem that the thing not to do was to use oil, in my experience it just leaks out of the gun and makes a revolting mess.

I am trying to find a modern equivalent to this grease, but the world has gone lithium based and not to sure if it is similar. Closest match so far is SKF LGMT 2 which is a mineral grease with a similar colour.

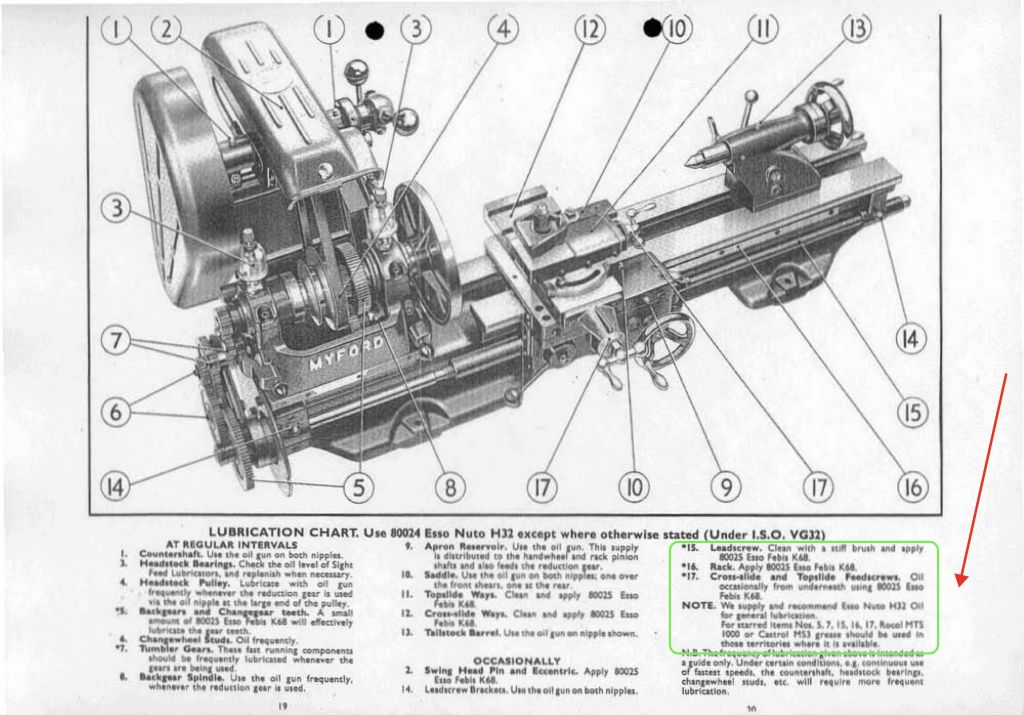

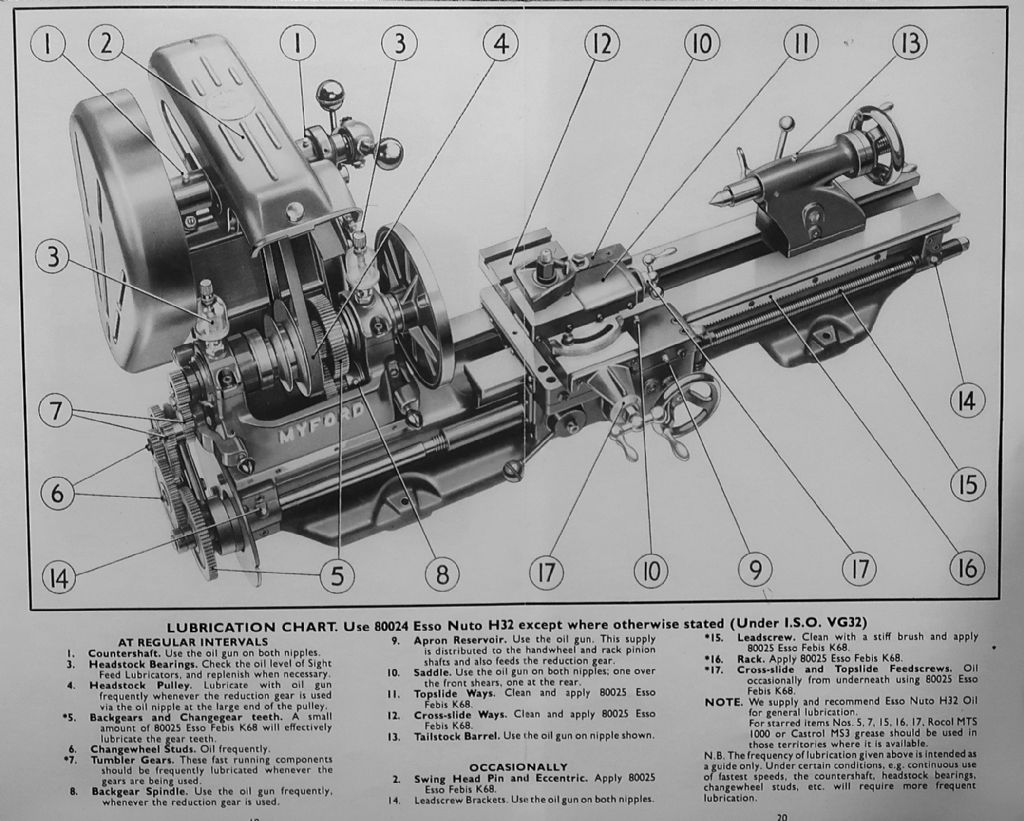

Don't really see any difference between oil or grease on a leadscrew for picking up contamination, both are sticky. But grease does seem better to lubricate things like the leadscrew end bearings, Norton box, change gears, feedscrews etc because it stays there, oils slowly run off.

Your right, it was essentially a grease gun that myford supplied and never designed to hold oil. I have since bought an oil gun from some german company that some recommended here. I havent had to use it yet but i believe you need to lengthen the shaft of it to reach one or two of the harder to reach nipples.

And as far as and difference between oil and grease attracting dirt, ive found this to be the same between both also.

Ive found a fine wire brush does a great job of cleaning shavings off the leadscrew. I will stick with grease, it seems to do the job and you dont need much of the stuff to work its way all over the leadscrew either.

Anyway, I just fitted both the new feedscrews to the lathe yesterday and they are working great!

All been lubed with moly grease and should last a fair few years I would say.

Nigel McBurney 1.