Posted by Roger Head on 28/12/2016 23:50:16:

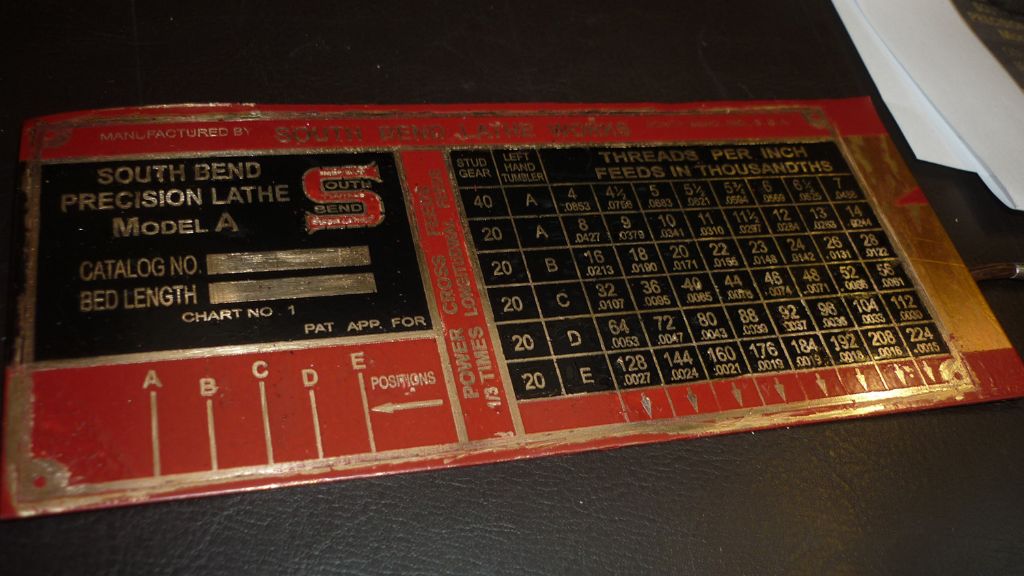

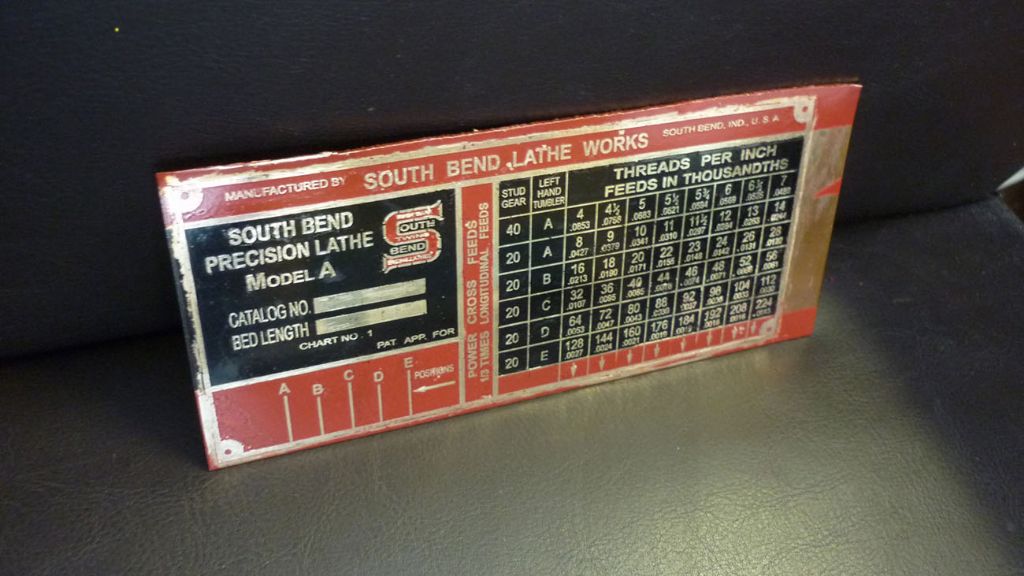

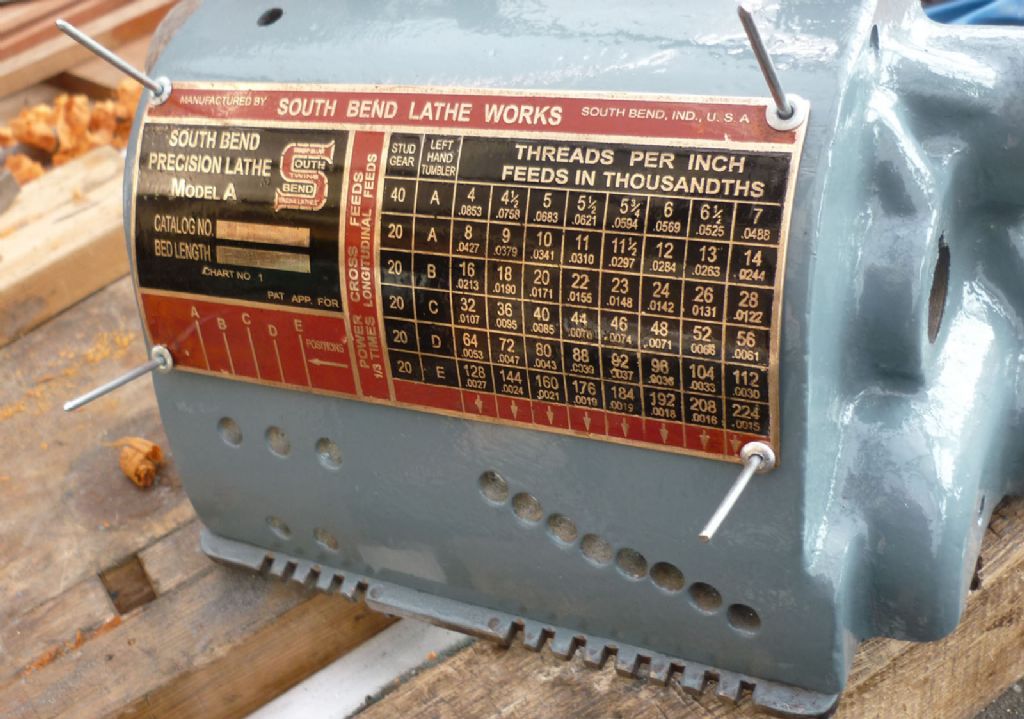

Hi Mark, that plate looks really good  . As you say, getting any real depth of etching consistently is very difficult, but if a shallow etch is acceptable, then getting sharp, high-resolution linework is quite straightforward.

. As you say, getting any real depth of etching consistently is very difficult, but if a shallow etch is acceptable, then getting sharp, high-resolution linework is quite straightforward.

I am particularly interested in the red and black infill that you have achieved – could you please give us some details on your method and materials for achieving that, and also some close-ups of the finished plate.

My 13 x 40 has no plate for the threading dial, only a table (in a poorly photo-copied manual) that looks like it was scratched out by a one-legged chicken clutching a blunt pencil! That page in the manual is now deteriorating through constant reference, so I've been 'thinking about doing something' (i.e. procrastinating) for a while.

Roger

Hi Roger, Sorry just noticed your post.

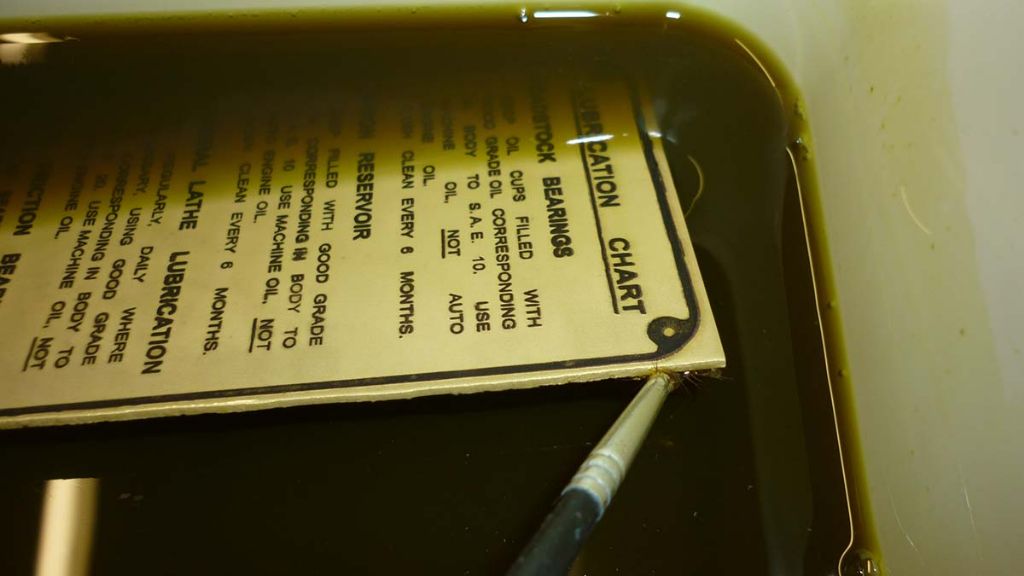

heres some more photos, this plate was my very first attempt, using a used Samsung ML 1860 b/w laser printer i bought on ebay for a tenner. Still had the Samsung proper toner cartridge in which worked great!

(but when i replaced the toner cartridge with a generic cheap replacement off ebay to do further plates ,it was rubbish,The toner wouldnt transfer properly using heat and was just crap, so anyone doing this be warned some toners don`t work with this method).

The red and black enamel was just two tins of Rustoleum painters touch spray from Wilkinsons. In black and Balmoral red.**LINK**

Because of the shallowness of the etch it was quite an ordeal to do. I masked off the main areas and sprayed them. Gave them a day to dry and then the hard bit carefully scraping off the paint from all the high spot (ie the letters/numbers,etc… It was almost impossible to not knock little bits of paint off here and there. I just touched it up with a very fine brush and a bit of spray paint sprayed onto a plastic yogurt lid.

Once i thought it looked ok ,i painted the all thing with a couple of coats of clear acrylic lacquer that i had lying around. as said the hardest bit is removing the paint from the high spots . I di try abrasive paper on a glass plate on another plate i did with some success, again the depth of etch makes it difficult..

RRMBK.