Posted by Absolute Beginner on 02/11/2017 23:16:32:

When measuring tight tolerances with an indicator, how hard should it be pushed against the measured surface to register a correct tolerance?

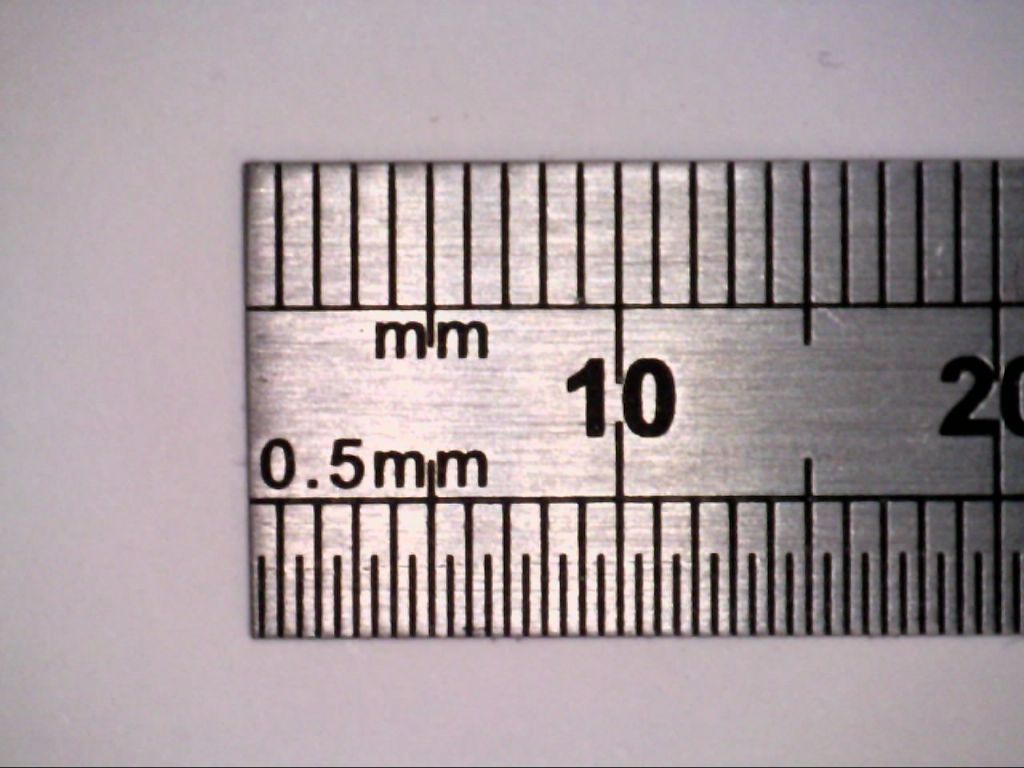

What do you consider to be a tight tolerence? What talking about indicators, are you also talking about micrometers, and digital calipers as well? Or are you jst talking about diat test indiactors? With dial test indicators, the rigidity of the stand holding the indicator can have an effect on the value that you are able to measure. The smaller the units you are measuring the more difficult the task of measuring becomes. If you are talking about 0.01mm , that is very easy to measure compared to 0.001mm or 0.0005mm. Sometimes , when working to very tight tolerences, specific gauging is often made, to be able to compare these part sizes. Particular when you are making parts where the size to be acheived needs to be less than 0.001mm. In the home shop, making round things, is achieveable to 0.001mm but not when milling.

Absolute Beginner.