Posted by IanT on 27/08/2017 10:10:54:

…

P.S. Hopper – I've never seen anyone mention that 'tapered' parting tools only have side clearance at the tip – and a small clearance should really be ground (both sides) back from the tip….

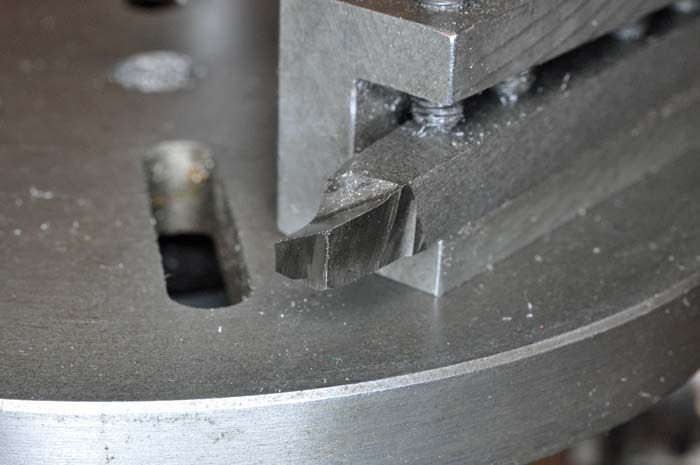

Hard to explain without diagrams, but yes I was referring to teh usual tapered cross section parting tools. Never seen grinding the sides for extra clearance be particularly successful. What I was attempting to explain was that if you grind back rake on, say, the first half inch of the top, going, say, 1/8 deep at the rear of the ground notch, if you then keep grinding off the front face of the parting tool to repeatedly sharpen it, as is usual, the cutting tip of the tool moves down that sloping ground top surface and thus moves down the tapered cross section, thus becoming narrower than the top of the unground tool blank, which may end up jammed in a deep groove if parting say 2" bar etc.

If you then try grinding the sides of the blade to make it fit into the groove, you end up with a blade getting narrower and narrower as you keep sharpening it and needing to create extra clearance.

That's why I grind the top of my parting blades dead flat all along. To sharpen, simply grind the front face. No further mucking about needed, no jamming, and no need to grind a half inch off the end of the tool when it gets too ground down to be useful and start all over again.

Piero Franchi.