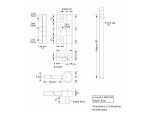

Unimat 3 milling head depth stop

by

–

One useful addition to the Unimat mill/ drill attachment that compliments the Unimat 3 lathe is a depth stop. Such an item is quickly and easily made with most of the dimensions tailored to suit the material available. One dimension to be aware of is the position of the lower fixing screw hole, which must avoid the quill clamping screw and nut in the Unimat casting. Another less important dimension is the length of the stop block, which is equal to the height of the Unimat head casting. This is only to make the accessory look more like an original part of the machine.

A slitting saw was used to make the 25thou. wide slot but a small hacksaw could be used if preferred. Although it is not shown on the photograph, a small ring was added to the top end of the stop rod, to prevent it from dropping out of the clamp housing. It is shown on the drawing of the stop bar. It could be a light press fit or fixed with a dab of Loctite. If preferred, a small anvil similar to those on a micrometer can be set in the top of the stop rod, with another in a corresponding position on the under side of the motor mounting plate.

Advert

Enjoy more Model Engineer & Model Engineers’ Workshop Magazine reading every month. Click here to subscribe.

Article Tags: